Bending, anti-reflection, low-radiation, easy-to-clean coated glass and manufacturing method thereof

A technology of low-emissivity coating and coated glass, which is applied in the direction of chemical instruments and methods, glass/slag layered products, layered products, etc. It can solve the problems of disturbing the driving line of sight, not easy to clean, time-consuming and labor-intensive, etc., to keep clean Bright, eliminate the effect of interfering with the driving line of sight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

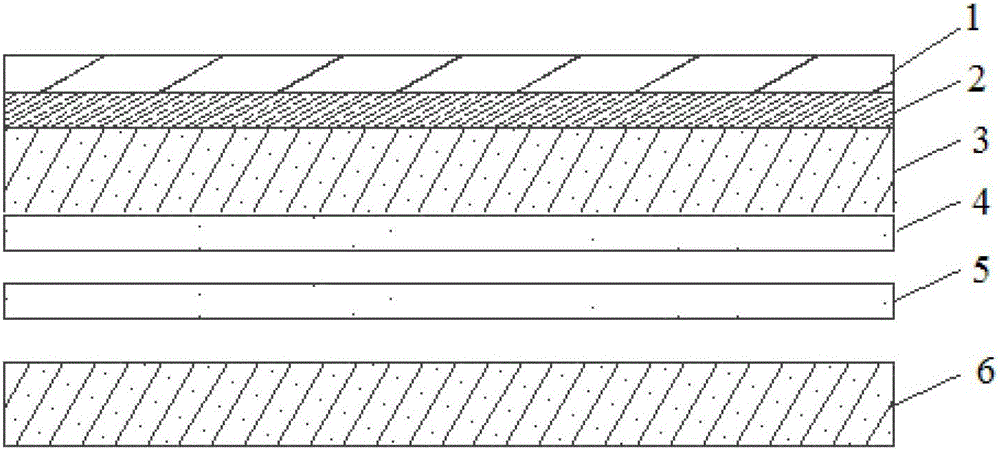

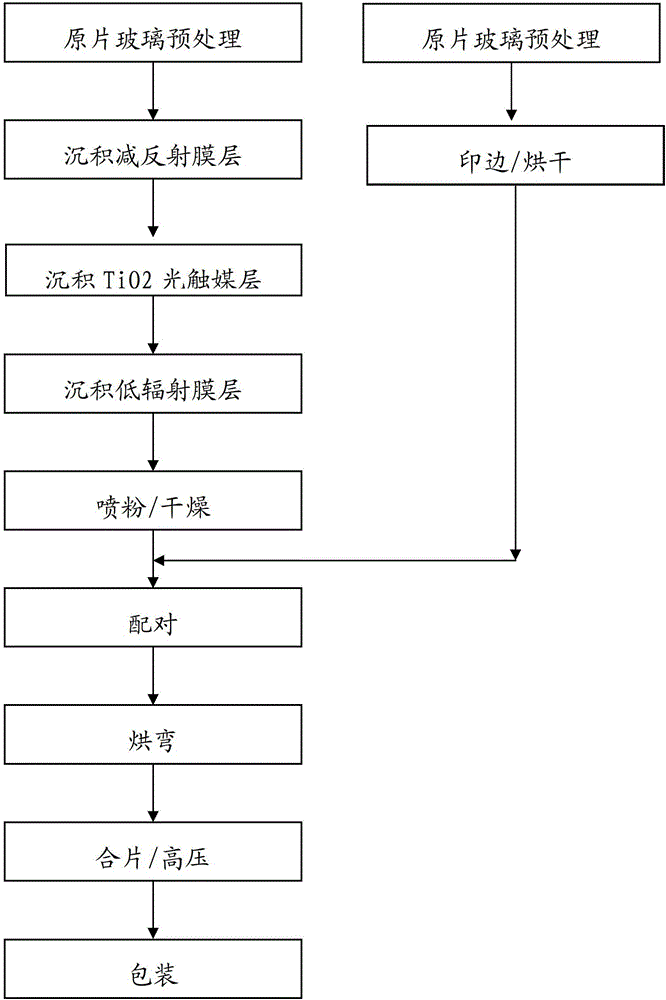

[0043] Such as figure 1 As shown, a kind of bakeable anti-reflection low-radiation and easy-to-clean coated glass is composed of anti-reflection and low-radiation coated glass, polyvinyl butyral (PVB) 5, and glass plate B6. Reflective low-radiation and easy-to-clean coated laminated glass, wherein the structure of the anti-reflective low-radiation coated glass is: TiO layered sequentially from top to bottom 2 The photocatalyst layer 1, the antireflection film layer 2, the glass plate A3 and the low radiation film layer 4 are composed.

[0044] The TiO 2 The thickness of photocatalyst layer 1 is 50-200nm; the thickness of anti-reflection film layer 2 is 219-230nm; the thickness of glass plate A3 is 1.6-2.5mm, the thickness of low-radiation film layer 4 is 80-130nm, and the thickness of PVB is 0.76mm , the thickness of the glass plate B is 1.6-2.5mm.

[0045] The anti-reflection film layer is composed of the first high refractive index film layer, the first low refractive ind...

Embodiment 2

[0066] A bendable, anti-reflection, low-radiation, and easy-to-clean coated glass. The glass is composed of anti-reflection, low-emission coated glass, polyvinyl butyral (PVB), and glass plate B in sequence. Clean coated laminated glass, wherein the structure of the anti-reflection and low-emissivity coated glass is: TiO layered sequentially from top to bottom 2 It consists of a photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer.

[0067] The TiO 2 The thickness of the photocatalyst layer is 50nm; the thickness of the anti-reflection film layer is 219nm; the thickness of the glass plate A is 1.6mm, the thickness of the low-emissivity film layer is 92nm, the thickness of the PVB is 0.76mm, and the thickness of the glass plate B is 1.6mm.

[0068] The anti-reflection film layer is composed of a first high-refractive-index film layer, a first low-refractive-index film layer, a second high-refractive-index film layer and a second lo...

Embodiment 3

[0076] A bendable, anti-reflection, low-radiation, and easy-to-clean coated glass. The glass is composed of anti-reflection, low-emission coated glass, polyvinyl butyral (PVB), and glass plate B in sequence. Clean coated laminated glass, wherein the structure of the anti-reflection and low-emissivity coated glass is: TiO layered sequentially from top to bottom 2 It consists of a photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer.

[0077] The TiO 2 The thickness of the photocatalyst layer is 200nm; the thickness of the anti-reflection film layer is 230nm; the thickness of the glass plate A is 2.5mm, the thickness of the low-emissivity film layer is 130nm, the thickness of the PVB is 0.76mm, and the thickness of the glass plate B is 2.5mm.

[0078] The anti-reflection film layer is composed of a first high-refractive-index film layer, a first low-refractive-index film layer, a second high-refractive-index film layer and a second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com