A glass processing production line

A production line and glass technology, applied in the direction of using tools for cleaning, cleaning methods and utensils, grain processing, etc., can solve problems such as low production efficiency, and achieve the effect of improving quality, ensuring cleanliness, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

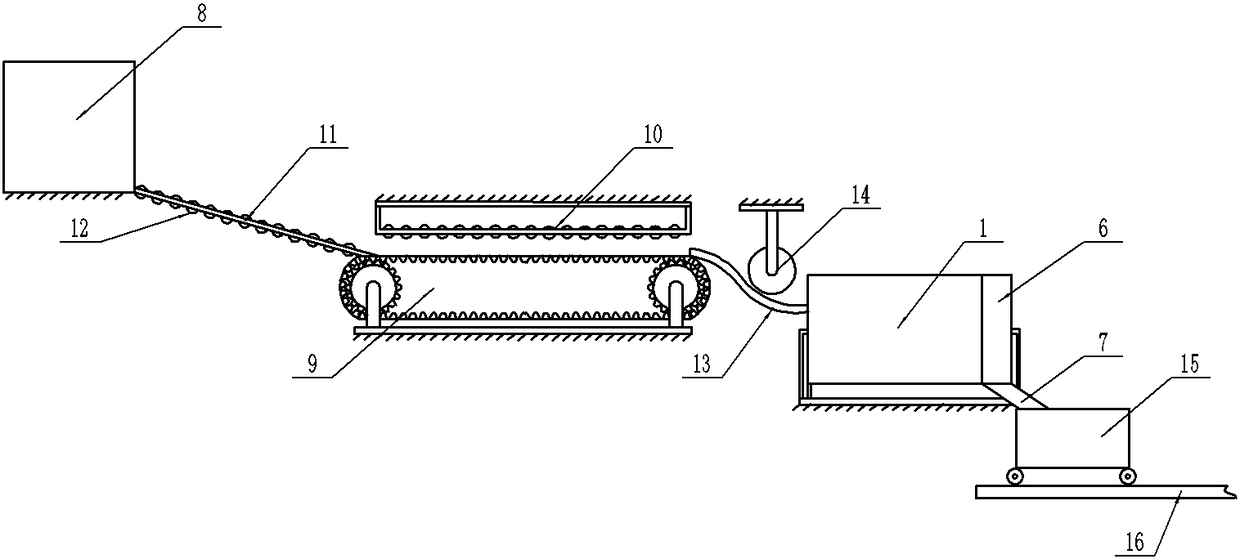

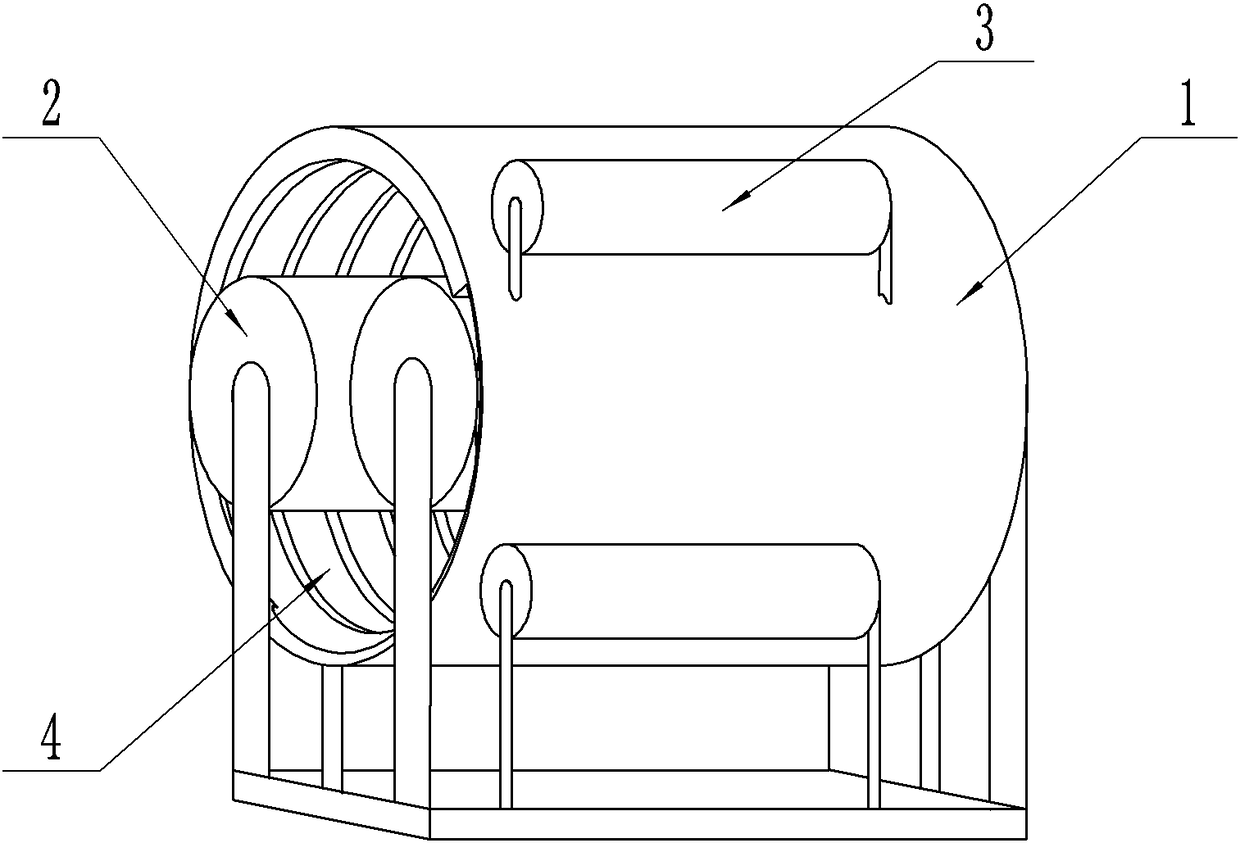

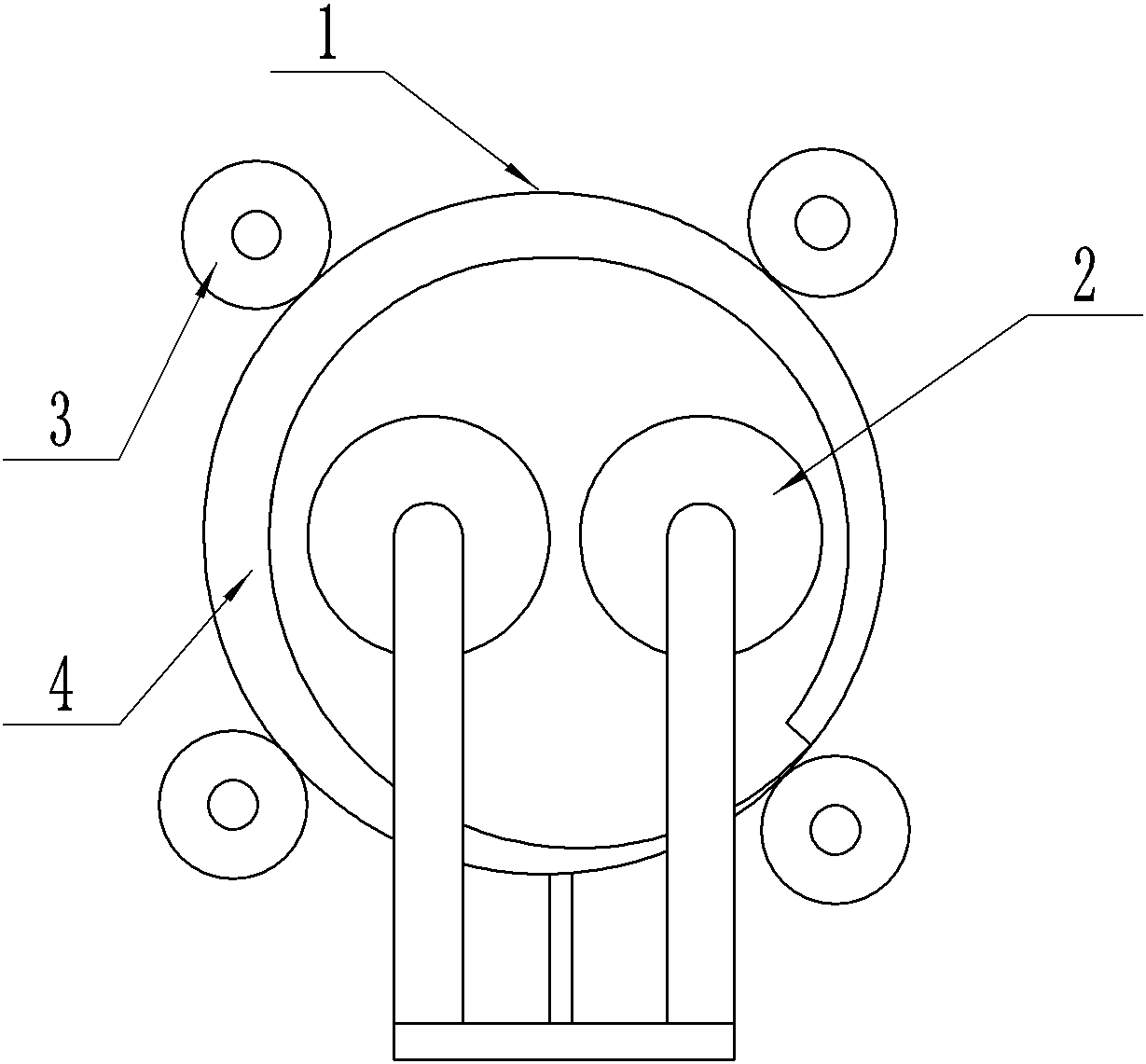

[0038] Embodiment A kind of glass processing production line is basically as attached figure 1 And attached figure 2 As shown, it includes a control mechanism, a water pump and a frame, and also includes a storage device, a cleaning conveying device, a preliminary crushing device, a rotating crushing device and a glass collection device arranged in sequence. The storage device includes a storage box 8, a storage box 8 is provided with discharge port.

[0039] The cleaning conveying device comprises a conveyor belt 9, a cleaning plate 10 arranged on the frame above the conveyor belt 9 and a cleaning channel 11 connecting the discharge port and the feed end of the conveyor belt 9, and a cleaning plate 10 and the conveyor belt 9 are formed between the cleaning plate 10 and the conveyor belt 9 for waste glass to pass through The passage of cleaning plate 10 and cleaning road 11 are all provided with some sponge rollers 12, cleaning road 11 is close to the sponge roller 12 of dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com