Hard coating film and touch panel using the same

A touch panel and hard coating technology, applied in layered products, synthetic resin layered products, instruments, etc., can solve problems such as scratches, splashing glass substrate fragments, damage to liquid crystal display elements, etc., and achieve the effect of preventing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

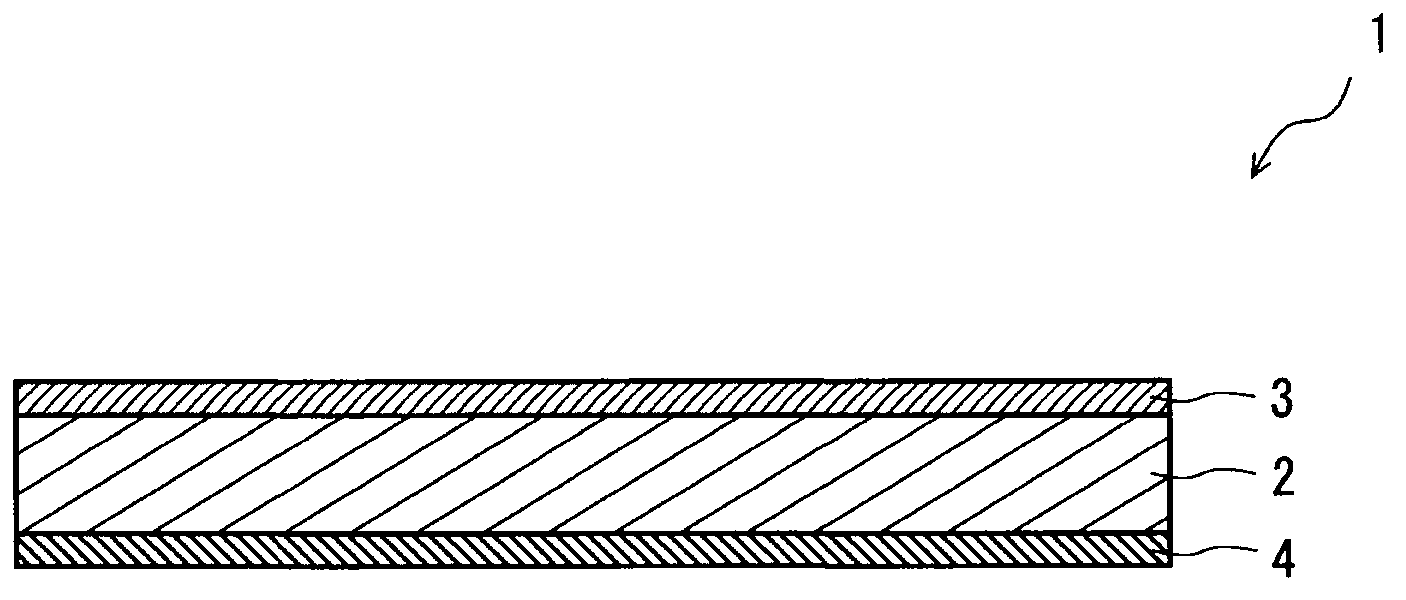

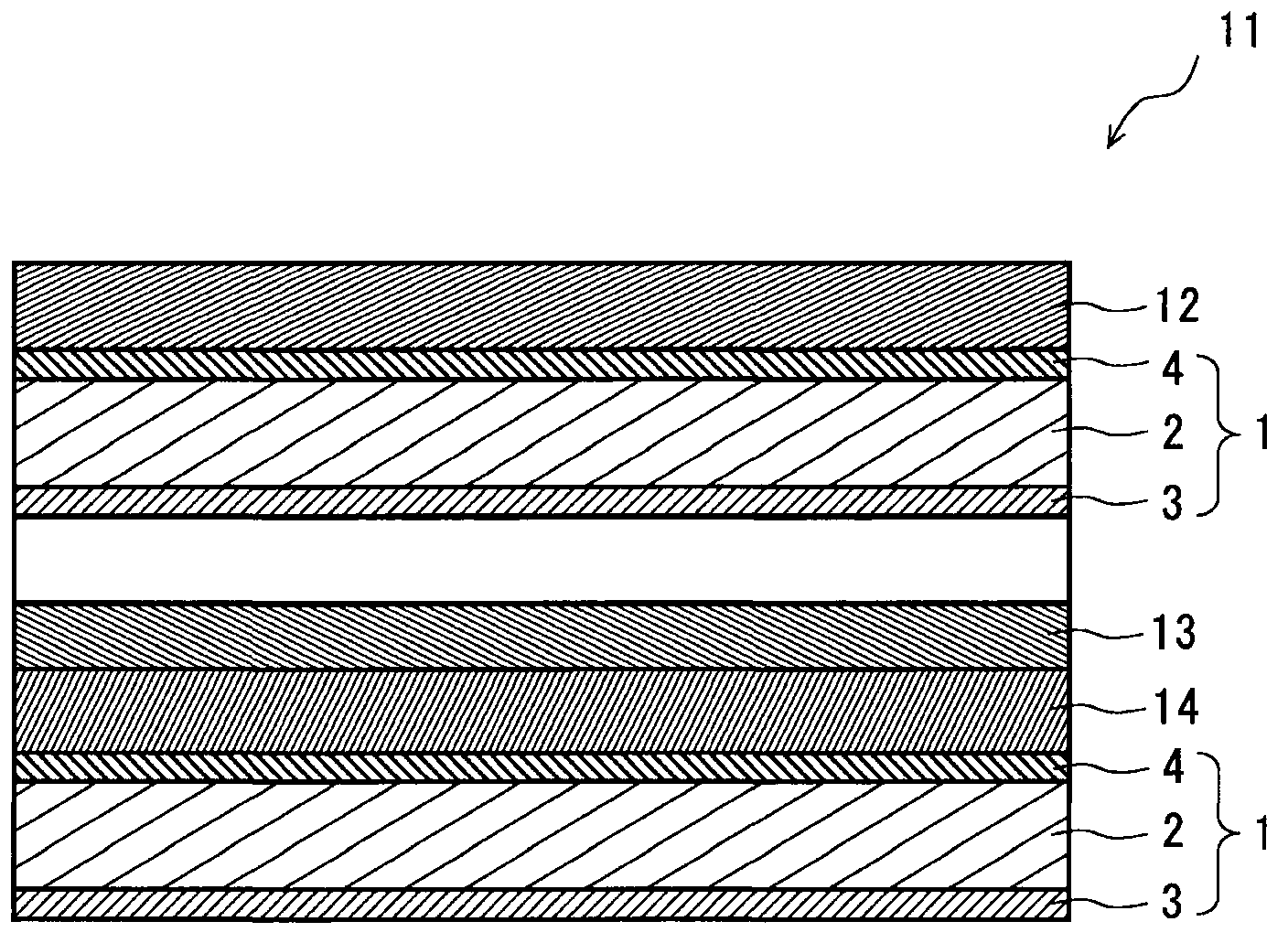

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to appropriate drawings.

[0033] figure 1 The hard coat film 1 has a base material layer 2 , a hard coat layer 3 and an adhesive layer 4 . In a touch panel-mounted liquid crystal display device, the hard coat film 1 is laminated on the glass substrate by attaching the adhesive layer 4 to the surface and / or the back surface of the glass substrate of the touch panel.

[0034] Since the base material layer 2 is required to transmit light, it is formed to be transparent, especially colorless and transparent. There are no particular restrictions on the main components constituting the base material layer 2, typically consisting of polycarbonate-based resins, cycloolefin-based resins, acrylic-based resins, polypropylene-based resins, and polyethylene terephthalate-based resins. Substances selected in the group. The aforementioned synthetic resin has excellent optical transparency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com