Ce:YAG fluorescent glass for white-light LED and preparation method of Ce:YAG fluorescent glass

A fluorescent glass and white light technology, applied in the field of low softening point Ce:YAG fluorescent glass and its preparation, can solve the problems of microcrystalline lattice defects, poor luminous effect, expensive price, etc. Effect of durability and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] By 48% PbO: 33% B 2 o 3 : 14% ZnO: 5% SiO 2 (mol ratio) Weigh the powder raw material, mix it and melt it, the temperature is 800 ° C, keep it warm for 3 hours, after the glass powder is obtained according to the above steps, add 3wt% Ce: YAG fluorescent micropowder, mix it and put it in a crucible, Put it directly into a resistance furnace at 600°C, keep it warm for 30 minutes, and then shape it. The annealing temperature is 300°C to obtain a fluorescent glass sheet.

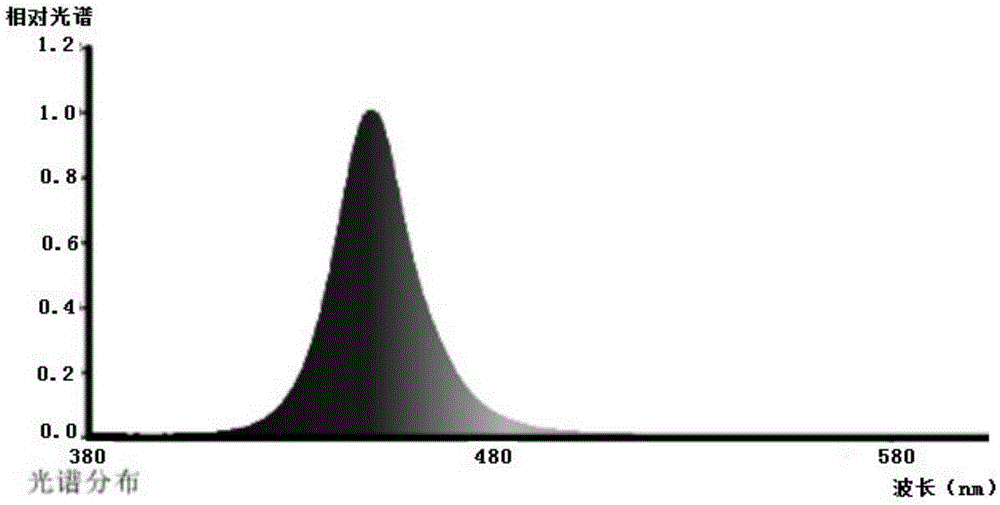

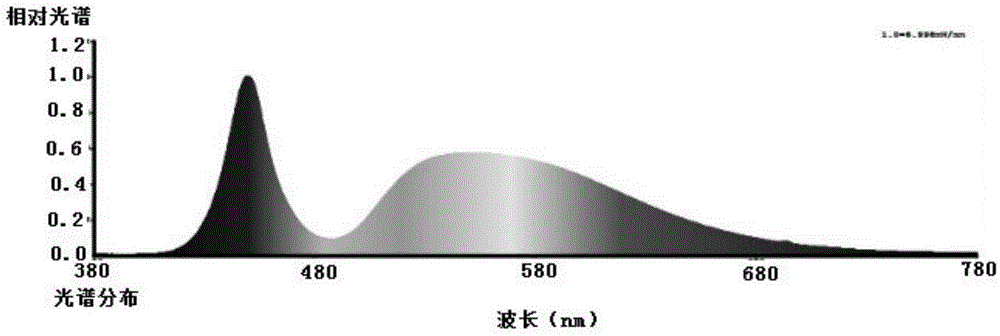

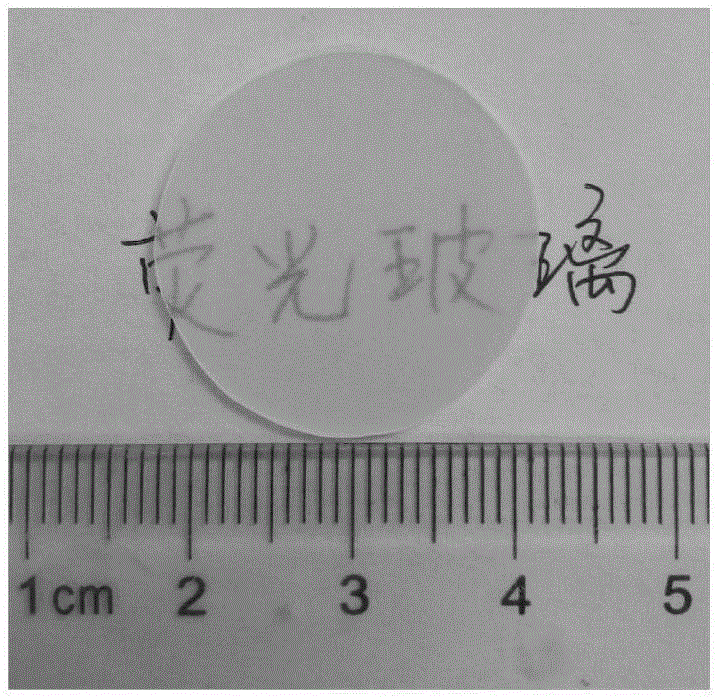

[0045] Fluorescent glass such as figure 1, Observation shows that the material prepared by this process has good uniformity, and the crystal phase containing yttrium aluminum garnet (YAG) has been uniformly distributed in the glass matrix. After the fluorescent glass sheet is ground and polished, it is packaged together with the blue light chip. figure 2 . image 3 It is a blue light spectrum diagram with a peak wavelength of 450nm. Under the excitation of the blue light, the fluorescent glass mate...

Embodiment 2

[0047] By 48% PbO: 33% B 2 o 3 : 14% ZnO: 5% SiO 2 (mol ratio) Weigh the powder raw material, mix it and melt it, the temperature is 800 ° C, keep it warm for 3 hours, after the glass powder is obtained according to the above steps, add 5wt% Ce: YAG fluorescent micropowder, mix it and put it in a crucible, Put it directly into a resistance furnace at 600°C, heat it for 30 minutes, and then shape it. The annealing temperature is 300°C to obtain a fluorescent glass sheet. After grinding and polishing, it is combined with the blue light emitted by the blue light chip to form positive white light.

Embodiment 3

[0049] By 48% PbO: 33% B 2 o 3 : 14% ZnO: 5% SiO 2 (mol ratio) Weigh the powder raw material, mix it and melt it, the temperature is 800°C, keep it warm for 3 hours, after the glass powder is obtained according to the above steps, add 2wt% Ce: YAG fluorescent micropowder, mix it and put it in a crucible, Put it directly into a resistance furnace at 600°C, heat it for 30 minutes, and then shape it. The annealing temperature is 300°C to obtain a fluorescent glass sheet. After grinding and polishing, it is combined with the blue light emitted by the blue light chip to form positive white light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com