Method for producing starting material for sintering

A manufacturing method and technology of raw materials, which are applied in the field of manufacturing raw materials for sintering, can solve the problems of reduced granulation strength, reduced usage, and poor air permeability of granulators, and achieve the effects of suppressing scattering, easy handling, and improved combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

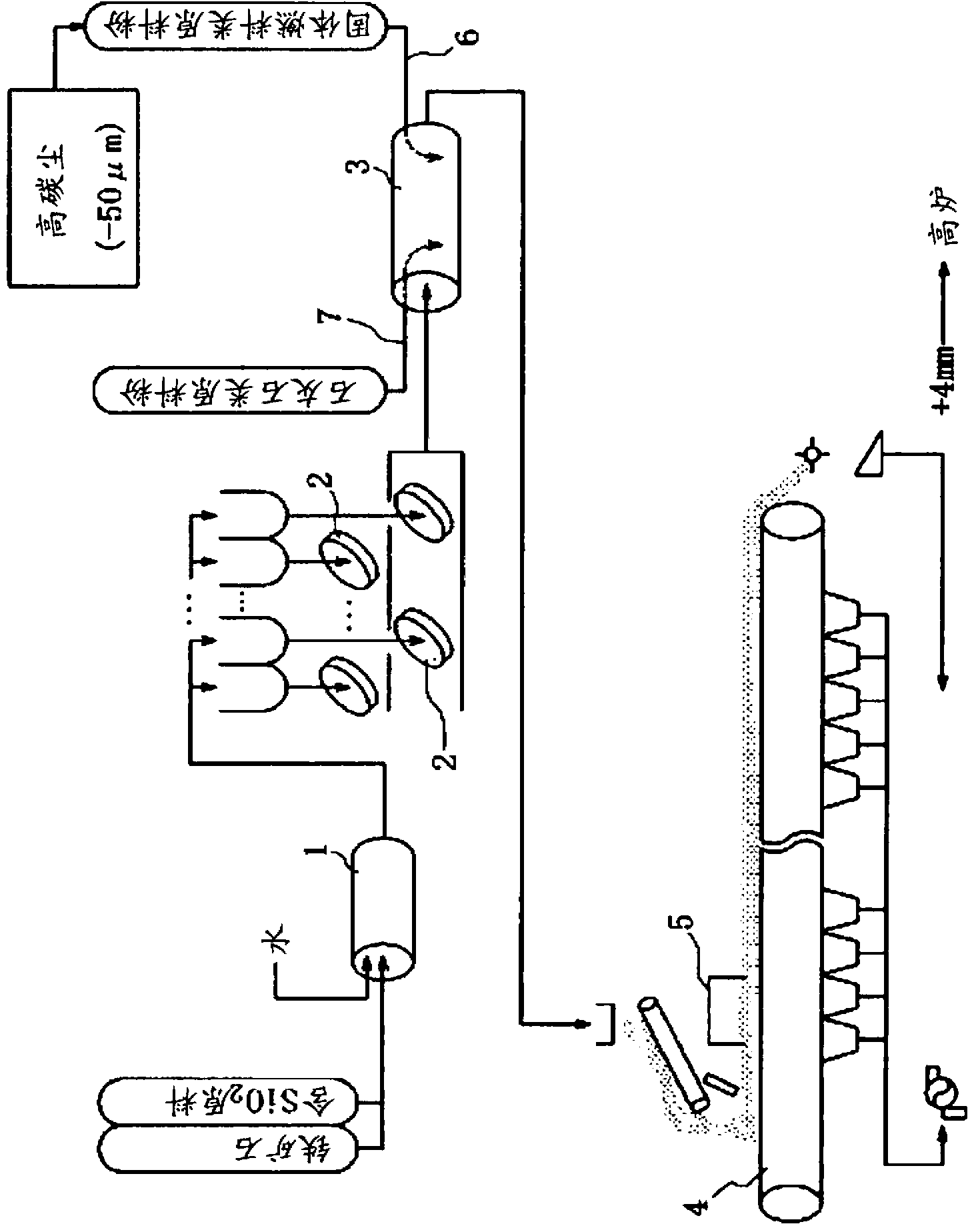

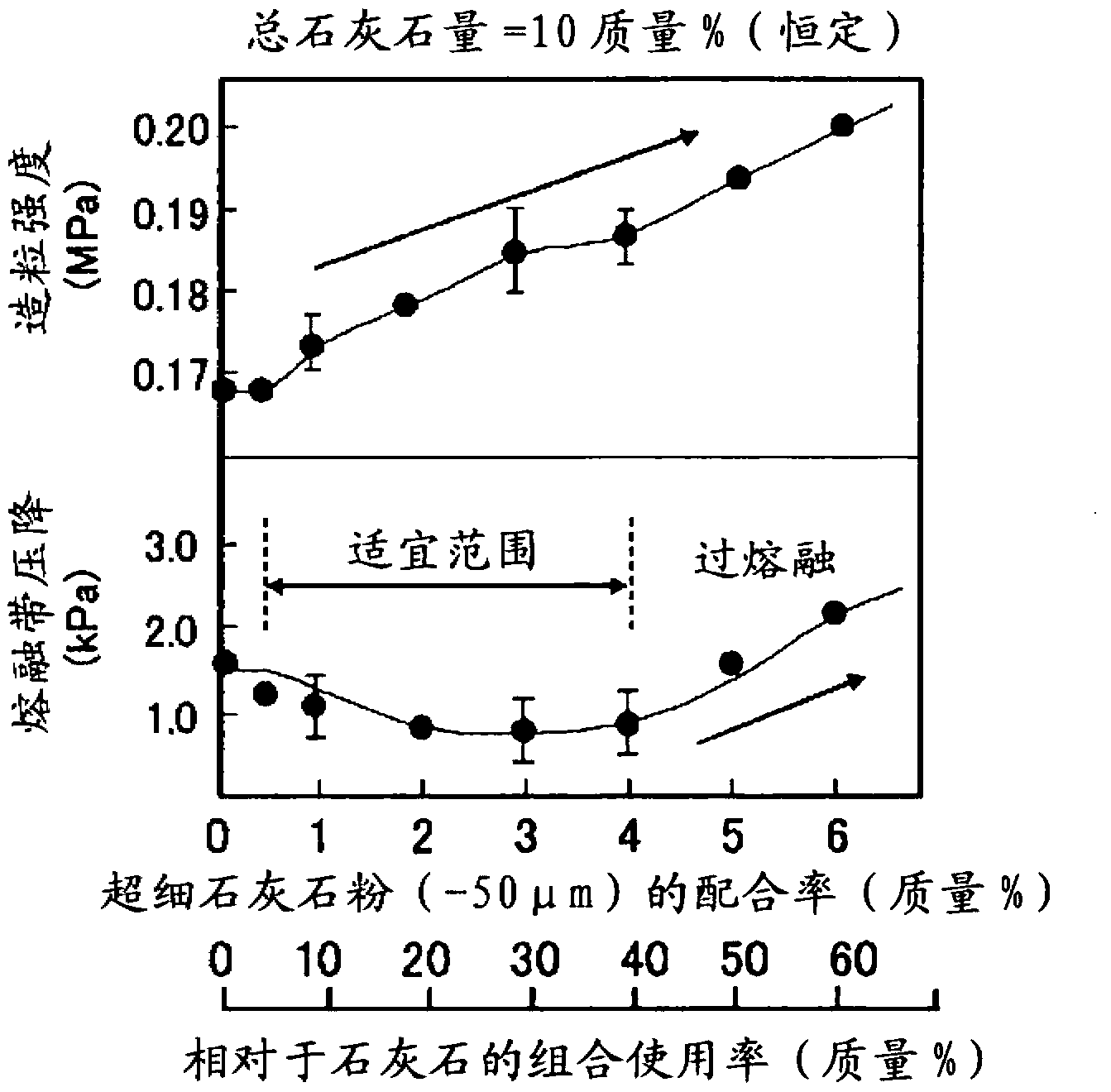

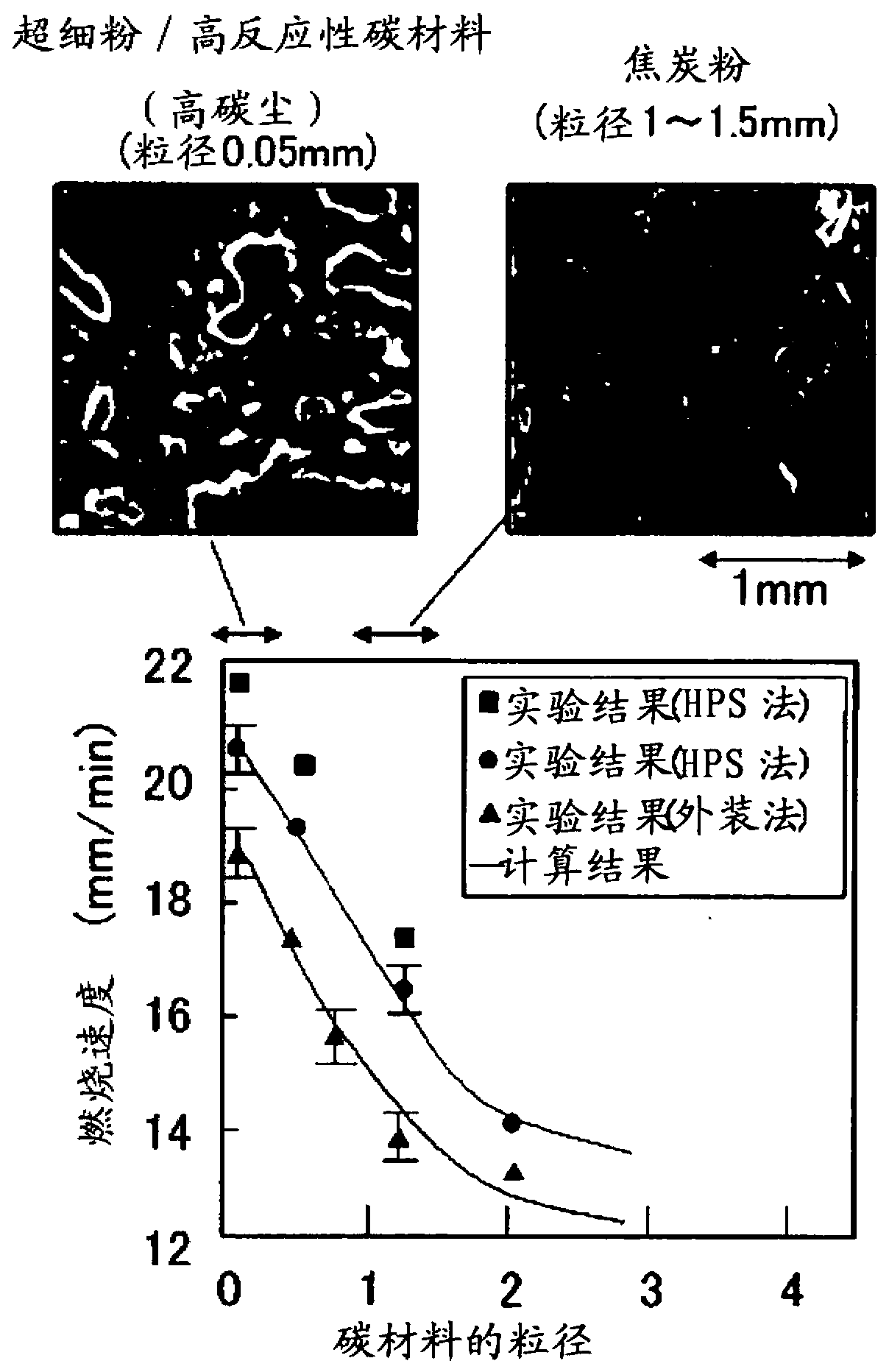

[0136] Such as figure 1 As shown, the iron ore and SiO 2 The raw materials are charged into the drum mixer 1 for stirring and mixing from the inlet to produce mixed raw materials. It should be noted that as a SiO-containing 2 As raw materials, silica or nickel slag is used. Next, the mixed raw material is charged into the pan granulator 2 and granulation is performed in the pan granulator 2 to obtain quasi-particles. Next, the obtained quasi-particles were charged into the outer layer forming drum mixer 3, and the quasi-particles were added at a position where the residence time until the quasi-particles reached the outlet of the outer layer forming drum mixer 3 was 40 seconds. The limestone-like raw material powder is 8% by mass of limestone with an average particle size of 1.2mm and 2% by mass of ultrafine limestone powder with an average particle size of 50μm (combined usage ratio relative to the total limestone: 20%), and reaches the outer layer 4% by mass of coke powder w...

Embodiment 2

[0144] In the same manner as in Example 1, various raw materials for sintering shown in Table 3 (Invention Examples 2, 3 and Comparative Example 3) were produced. Table 3 shows, for example, the mixing ratio of raw materials in each raw material for sintering.

[0145] Inventive example 2 uses 20% by mass of ultra-fine limestone powder relative to the total limestone combination. Inventive example 3 uses 20% by mass of ultrafine limestone powder relative to the total limestone combination, and at the same time uses high carbon relative to the total coke combination. 20% by mass of dust. It should be noted that the external loading time is 40 seconds for limestone powder and 20 seconds for coke powder.

[0146] The results of studying the sintering time, yield, and productivity when sintering each raw material for sintering thus obtained are compared and shown in Picture 9 .

[0147] [table 3]

[0148] Mixing ratio (mass%)

[0149] Such as Picture 9 As shown, compared with Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com