Substrate conveyer, substrate conveying method and coating, developing apparatus

一种基板搬送、基板的技术,应用在显影装置,涂布领域,能够解决没有记载、飞散并转印到晶片W上等问题,达到抑制液滴飞散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

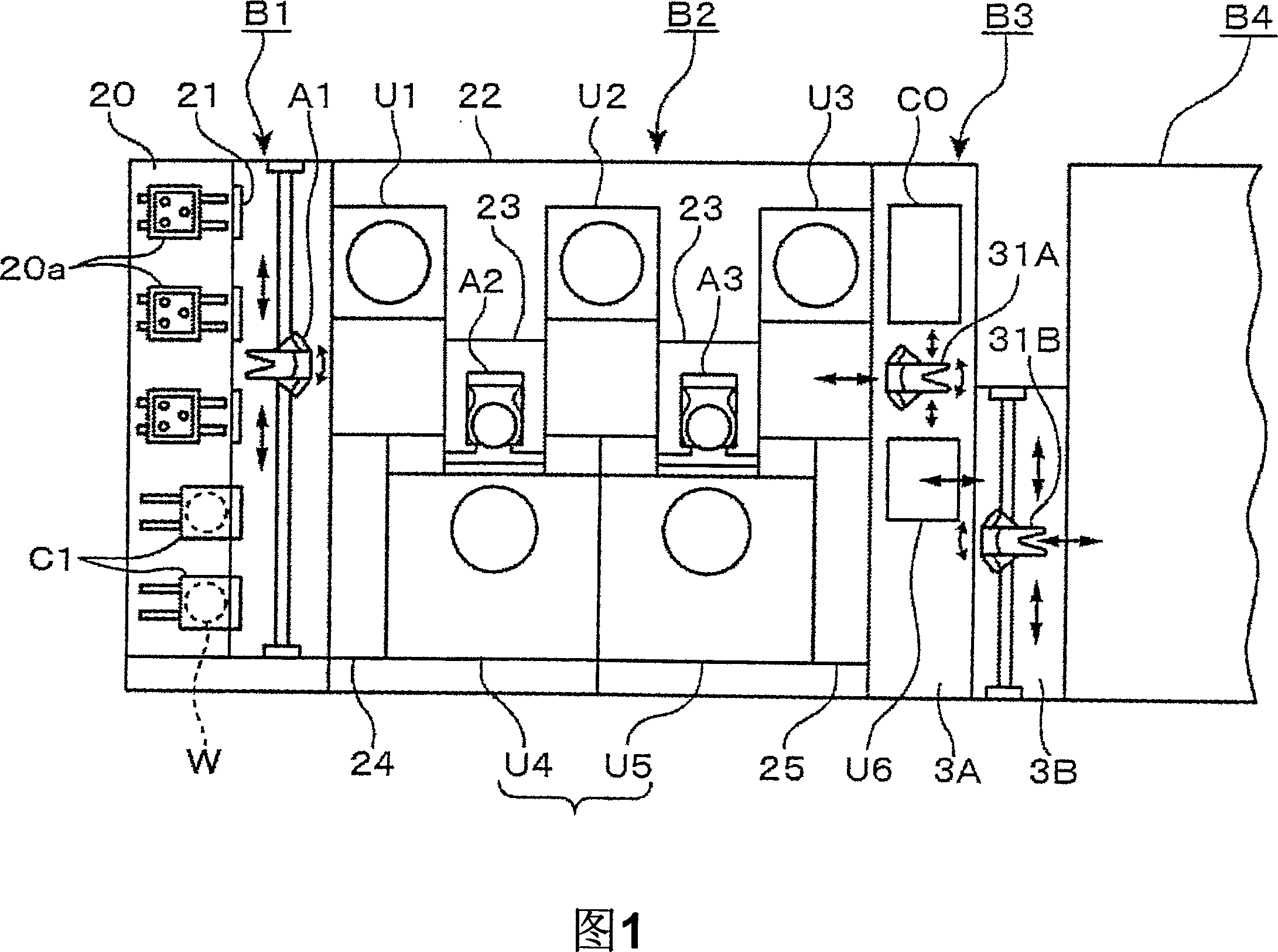

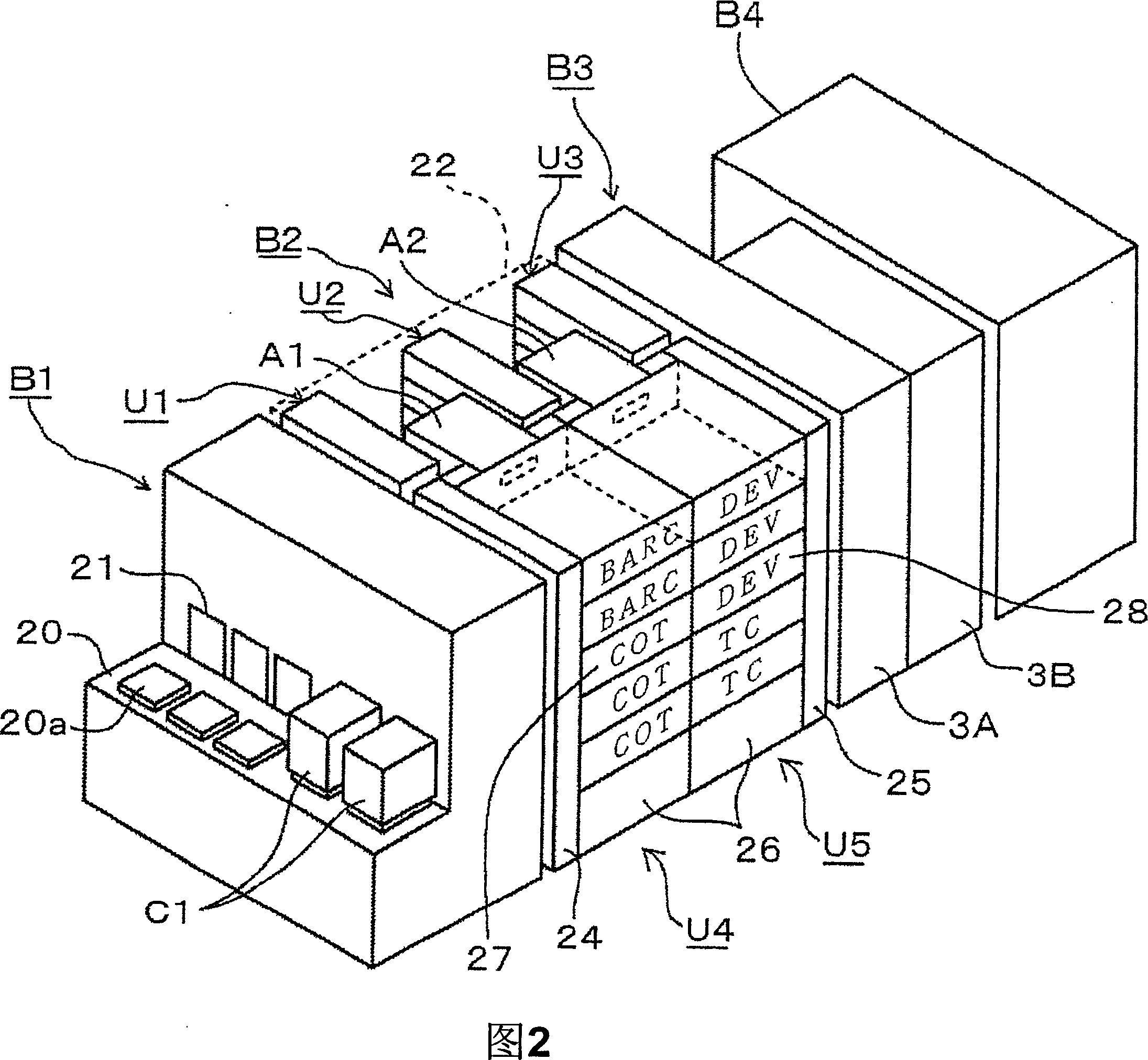

[0046] Referring to FIG. 1 and FIG. 2 , the overall structure of a system for applying an embodiment of the present invention to liquid immersion exposure will be briefly described. This system is a system composed of an exposure device connected to a coating-development device. B1 in the figure is provided with a loading unit 20a including a carrier (carrier) C1 for loading and unloading substrates such as 13 wafers W in a sealed manner. The carrier station (carrierstation) 20, the switch part 21 provided on the front wall surface when viewed from the carrier station 20, and the transfer mechanism A1 for taking out the wafer W from the carrier C1 through the switch part 21.

[0047] The inner side of the carrier mounting part B1 is connected to the processing part B2 surrounded by the frame body 22. In the processing part B2, the shelf units in which the heating-cooling system units are multi-staged are arranged alternately in order from the front side. U1, U2, U3 and main tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com