Process for producing rubber-wet masterbatch, rubber composition, and tire

A manufacturing method and masterbatch technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of poor operability, low carbon black yield, and insufficient carbon black dispersibility, and achieve easy preparation. , The effect of suppressing scattering and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058]

[0059] In the present invention, the slurry (A) is preferably a slurry formed by dispersing a filler material in a dispersion medium using a high-speed shear mixer, and the filler material includes carbon black granules in an undried state, and At least one substance selected from silica and the inorganic filler represented by the aforementioned general formula (1) is used as needed.

[0060] In the present invention, the high-speed shear mixer used to prepare the slurry (A) is a high-speed shear mixer composed of a rotor and a stator part, and a high-speed rotating rotor and a fixed stator are arranged through a narrow gap, and the Spin to generate high shear rates.

[0061] High-speed shear means that the shear rate is usually above 2000 / s, preferably above 4000 / s.

[0062] Commercially available high-speed shear mixers include Homogeneous Mixer manufactured by Special Mechanized Industry Co., Ltd., colloid mill manufactured by PUC Company of Germany, Cavitron (e...

Embodiment 1

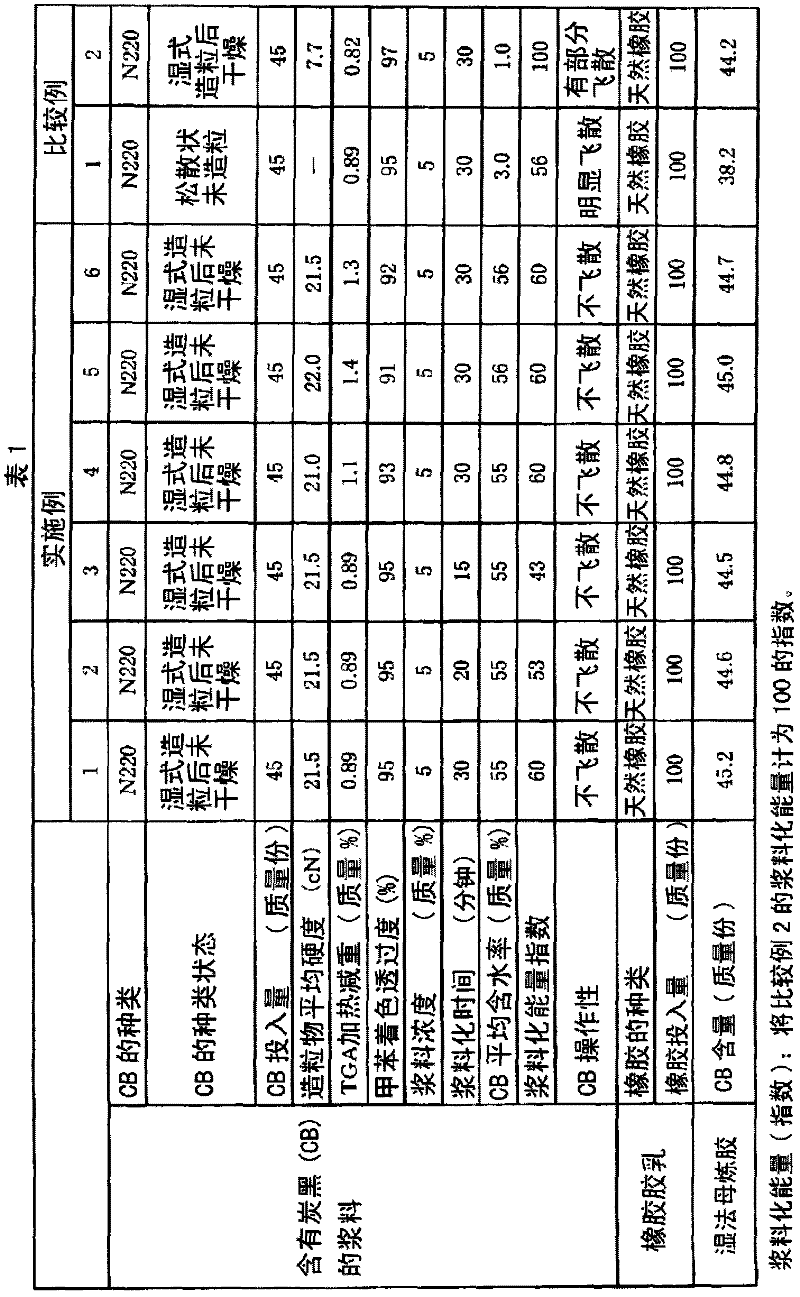

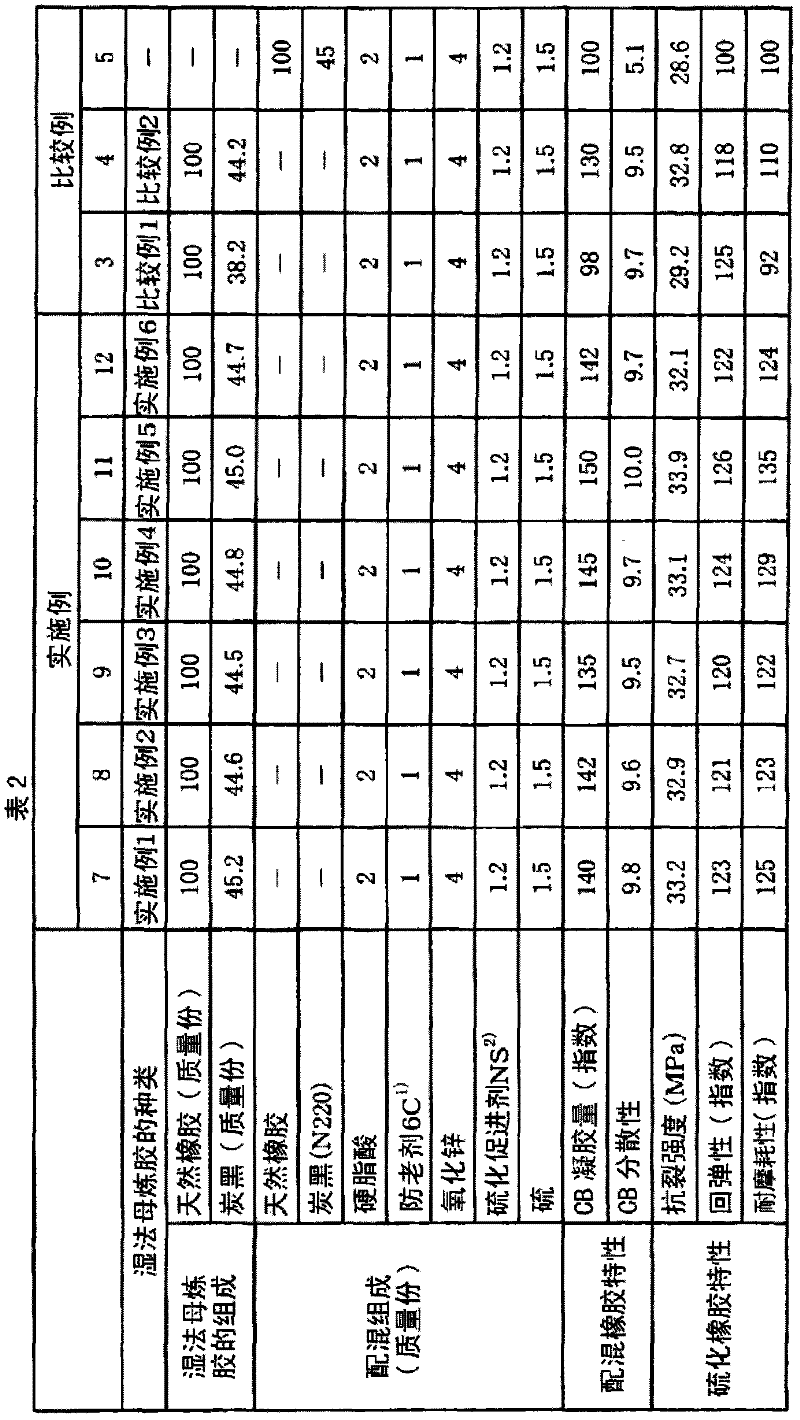

[0154] (1) Preparation of carbon black slurry

[0155] Throw into water the carbon black (N220: average diameter 1.7mm, average hardness 21.5cN, from the wet granulation of wet granulation of 52 mass % average water content rate 45 mass parts in dry weight conversion, average water content, when manufacturing carbon black The carbon black that takes out at the outlet of the granulator), with the high-shear mixer that Silverson Company manufactures, carry out the slurry processing of 30 minutes with the rotating speed of 4800rpm, make the slurry that contains carbon black of about 5 mass % of slurry concentration . Wherein, the preparation of carbon black slurry is carried out on the scale of 20kg slurry. The particle size distribution of carbon black in the slurry obtained at this time was volume average particle diameter mv=4.9 μm, D90 (90 volume % particle diameter)=8.3 μm.

[0156] In addition, the 24M4DBP oil absorption of carbon black (CB) before dispersion is 99mL / 100g...

Embodiment 2

[0162] (1) Preparation of carbon black slurry

[0163] Except having changed the slurrying processing time in Example 1 (1) into 20 minutes, it carried out similarly to Example 1 (1), and produced the slurry containing carbon black with a slurry density|concentration of about 5 mass %. The particle size distribution of carbon black in the slurry obtained at this time was volume average particle diameter mv=5.1 μm, D90 (90 volume % particle diameter)=8.4 μm.

[0164] In addition, the 24M4DBP oil absorption of carbon black (CB) before dispersion is 99mL / 100g, the 24M4DBP oil absorption of slurry recovery dry CB is 97mL / 100g, the retention rate of DBP oil absorption ([the 24M4DBP oil absorption of slurry recovery dry CB / The 24M4DBP oil absorption of CB before dispersion]×100) was 98%.

[0165] Furthermore, the slurrying energy index was 53.

[0166] (2) Manufacture of wet masterbatch

[0167] Using all the carbon black-containing slurries obtained in the above (1), a wet mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com