Method for producing starting material for sintering

A manufacturing method and technology of raw materials, applied in the field of manufacturing raw materials for sintering, can solve problems such as inability to obtain sufficient effects, mixing of micro-powdered coke in the filling layer, and reduction of coke powder coating amount, so as to shorten the time for external assembly, improve productivity, Powder produces a lightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

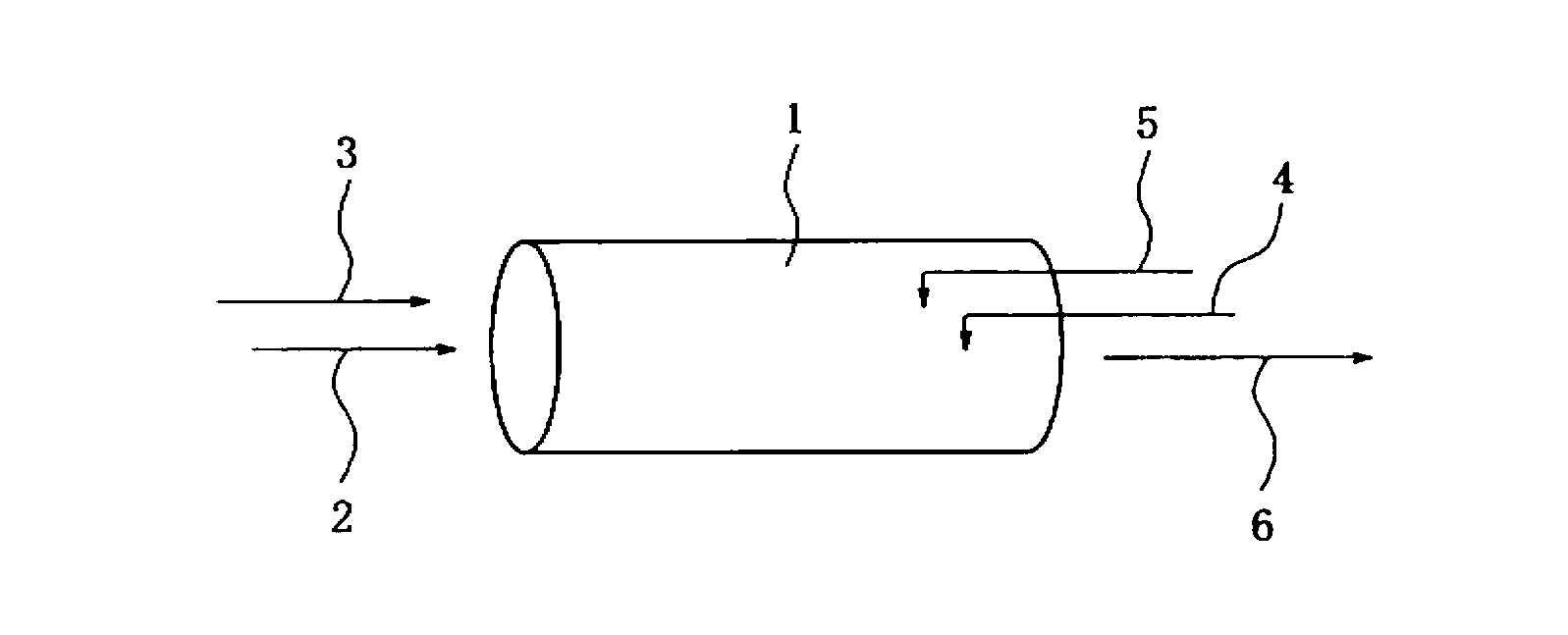

[0144] Such as figure 1 As shown, iron ore 2 and containing SiO 2 The raw material 3 is charged into the tumble mixer 1 from the inlet for granulation. It should be noted that, as a SiO-containing 2 Raw material 3 used silica or nickel slag. In the tumble mixer 1, iron ore 2 and SiO-containing 2 Raw material 3 was granulated to become quasi-particles, and limestone with an average particle diameter of 1.2 mm was added as limestone-based raw material powder 4 at a position where the residence time of the quasi-particles reached the outlet of the tumble mixer 1 was 40 seconds. 8% by mass and 2% by mass of superfine limestone powder with an average particle size of 50 μm (combined use ratio to the total limestone: 20%), and coke powder 4 with an average particle size of 0.9 mm as solid fuel raw material powder 5 % by mass and 1% by mass of high carbon dust with an average particle diameter of 50 μm (combined use ratio to total coke: 20%). In addition, the specific addition m...

Embodiment 2

[0153] In the same manner as in Example 1, various raw materials for sintering shown in Table 3 (invention examples 2 and 3 and comparative example 3) were produced. Table 3 shows the mixing ratio of raw materials in each raw material for sintering.

[0154] Invention Example 2 is a case where 20% by mass of ultrafine limestone powder is used in combination with the total limestone, and Invention Example 3 is a combination of 20% by mass of ultrafine limestone powder with respect to the total limestone, and high-carbon powder is used in combination with the total coke. The case where the dust is 20% by mass. It is to be noted that the exterior time was 40 seconds in Invention Examples 2 and 3, and 80 seconds in Comparative Example 3.

[0155] The sintering time, yield, and productivity of the sintering raw materials thus obtained were compared and compared, and are shown in Figure 8 .

[0156] [table 3]

[0157] Mixing ratio (mass%)

[0158] Such as Figure 8 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com