Motor actuator

A technology of actuators and motors, applied in the direction of electric components, casings/covers/supports, control of mechanical energy, etc., can solve problems such as abnormal sound, failure to obtain predetermined driving force, etc., and achieve the effect of preventing flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

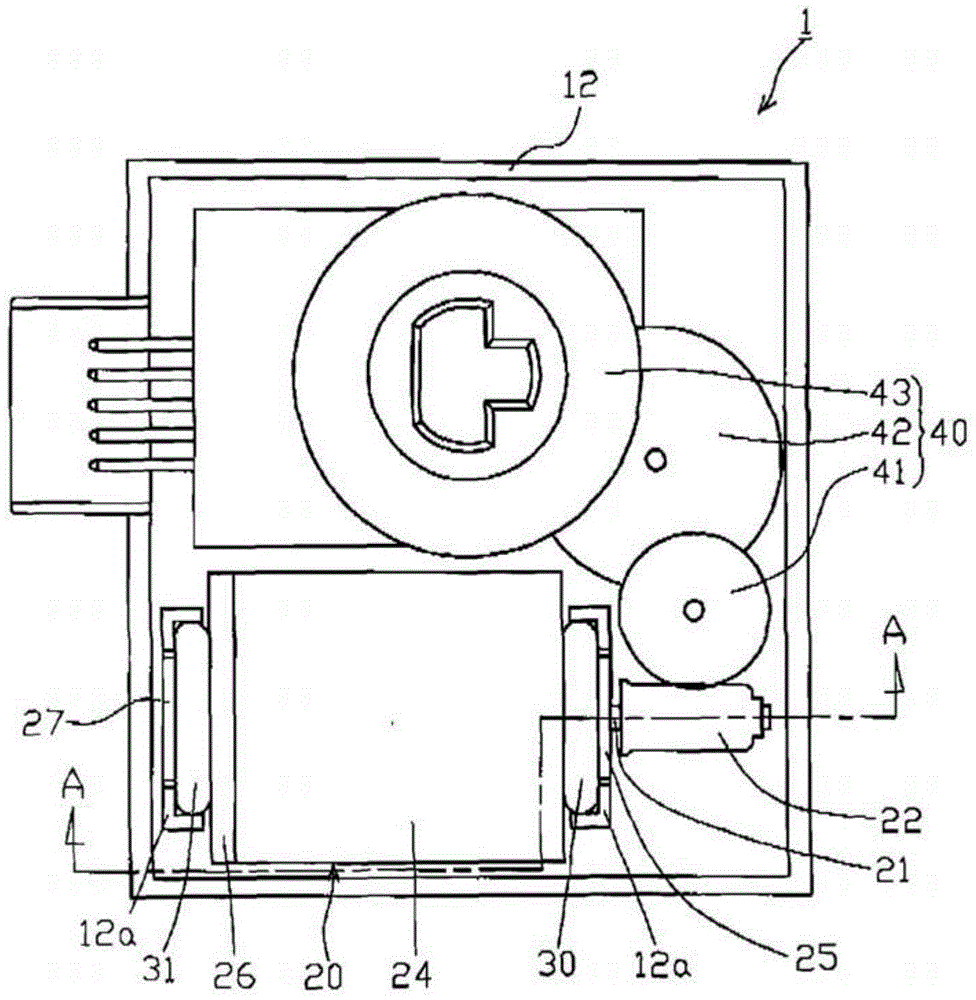

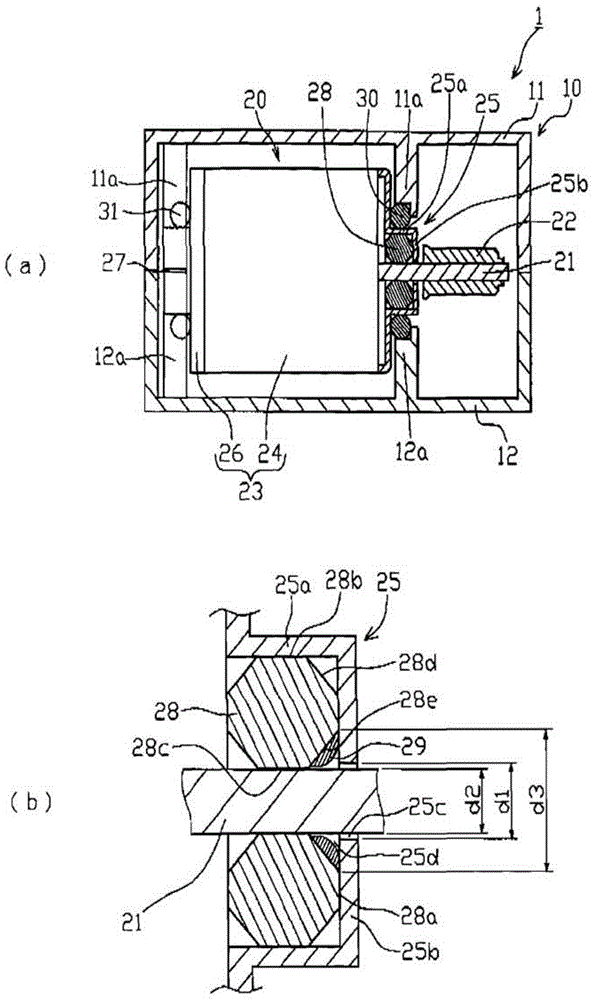

[0056] Such as figure 1 and figure 2 As shown, the motor actuator 1 of this example is used as a drive source for an air flow adjustment valve of an air conditioner used in vehicles such as automobiles, and accommodates a motor 20 in a casing 10 having a space inside and rotates the motor 20. The deceleration mechanism 40 for deceleration.

[0057] The case 10 has an upper case 11 and a lower case 12 made of hard resin, and the opening ends of the upper case 11 and the lower case 12 are fitted into each other to form a box shape having a predetermined internal space. In addition, since the fitting structure of the upper case 11 and the lower case 12 is not an essential part of the present invention, it is omitted from the drawings.

[0058] The motor 20 of this example is constituted by a DC motor with a brush, and has a motor case 23 and a rotating shaft 21 having a space inside. One end of the rotating shaft 21 protrudes to the outside of the motor case 23 , and a worm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com