Mat member, method of fabrication mat member, exhaust gas treating apparatus, and silencing device

一种废气处理装置、废气处理的技术,应用在消音装置、排气装置、薄料处理等方向,能够解决降低无机纤维飞散量、不能充分抑制无机纤维飞散等问题,达到抑制飞散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2~5

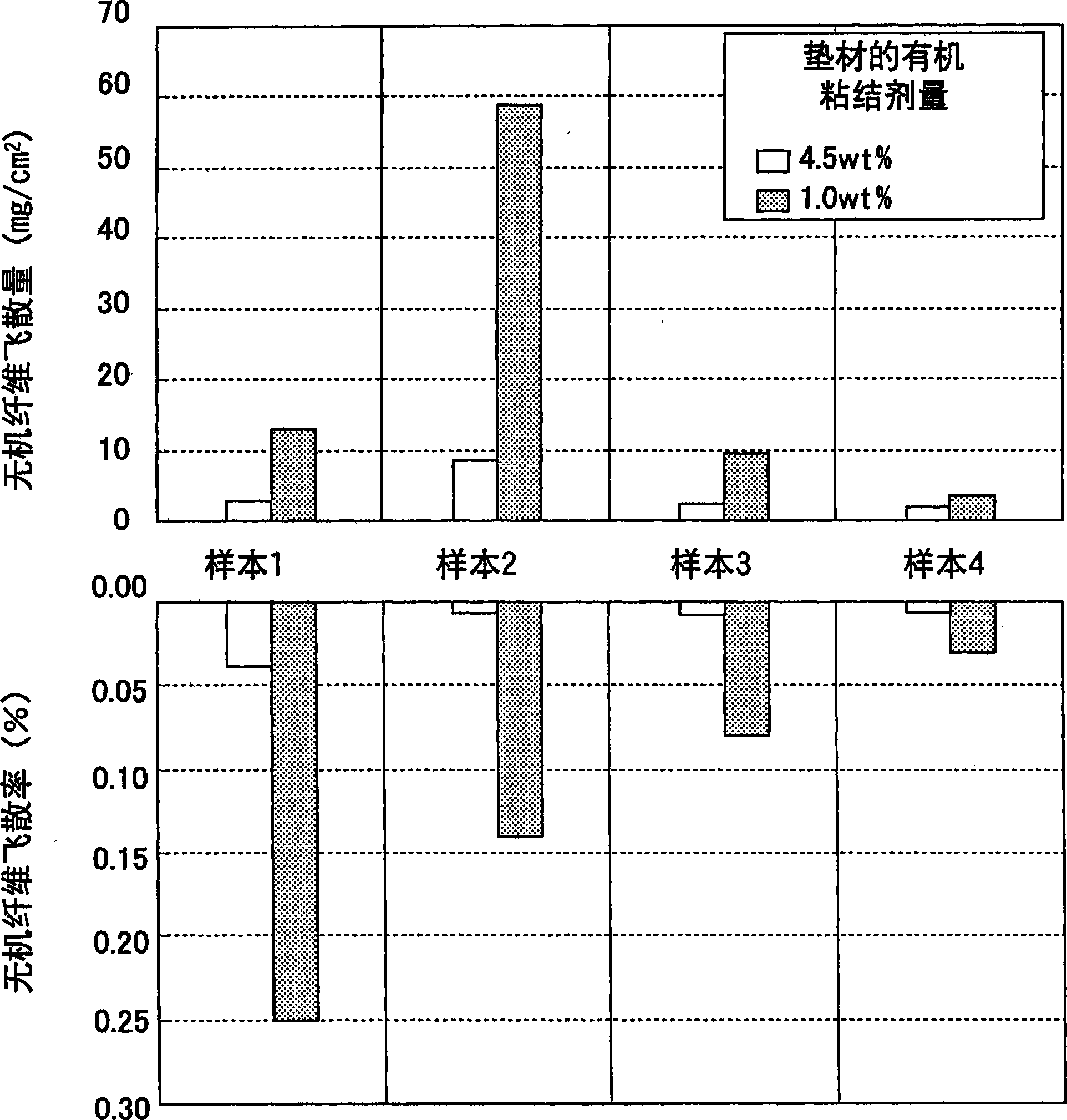

[0103] In the same manner as in Example 1, a mat having an inorganic fiber scattering suppressing portion on the entire end surface was produced (Examples 2 to 5). However, in Example 2, the installation density of the organic binder was 6.2 mg / cm 2 , in embodiment 3, make the setting density of organic binding material be 10.7mg / cm 2 , in embodiment 4, make the setting density of organic binding material be 15.1mg / cm 2 , in embodiment 5, make the setting density of organic binding material be 24.3mg / cm 2 .

Embodiment 6~8

[0105] A mat having an inorganic fiber scattering suppressing portion on the end face was fabricated by the same method as in Example 1. However, in Example 6, the organic binder was spray-coated only on 25% of the entire end surface of the mat to form the inorganic fiber scattering suppressing portion. In Example 7, the inorganic fiber scattering suppressing portion was formed on 50% of the entire end surface of the mat, and in Example 8, the inorganic fiber scattering suppressing portion was formed on 75% of the entire end surface of the mat. Among them, the installation density of the organic binder in any one of the inorganic fiber scattering suppression parts is 1.8 mg / cm 2 .

Embodiment 9

[0107] A mat having an inorganic fiber scattering suppressing portion was produced in the same manner as in Example 1. However, in Example 9, the first organic binder was also spray-coated on the entire surface of one main surface (first main surface) of the mat material. Therefore, the inorganic fiber scattering suppressing portion is formed on the entire surface of one main surface (first main surface) of the mat material in addition to the entire end surface of the mat material. The installation density of the first organic binder in the inorganic fiber scattering suppressing portion (end face and first main surface) is 1.8 mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com