Outdoor unit

An outdoor unit and compressor technology, applied in the field of outdoor units, can solve the problems of glass fiber fiber scattering, powder scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

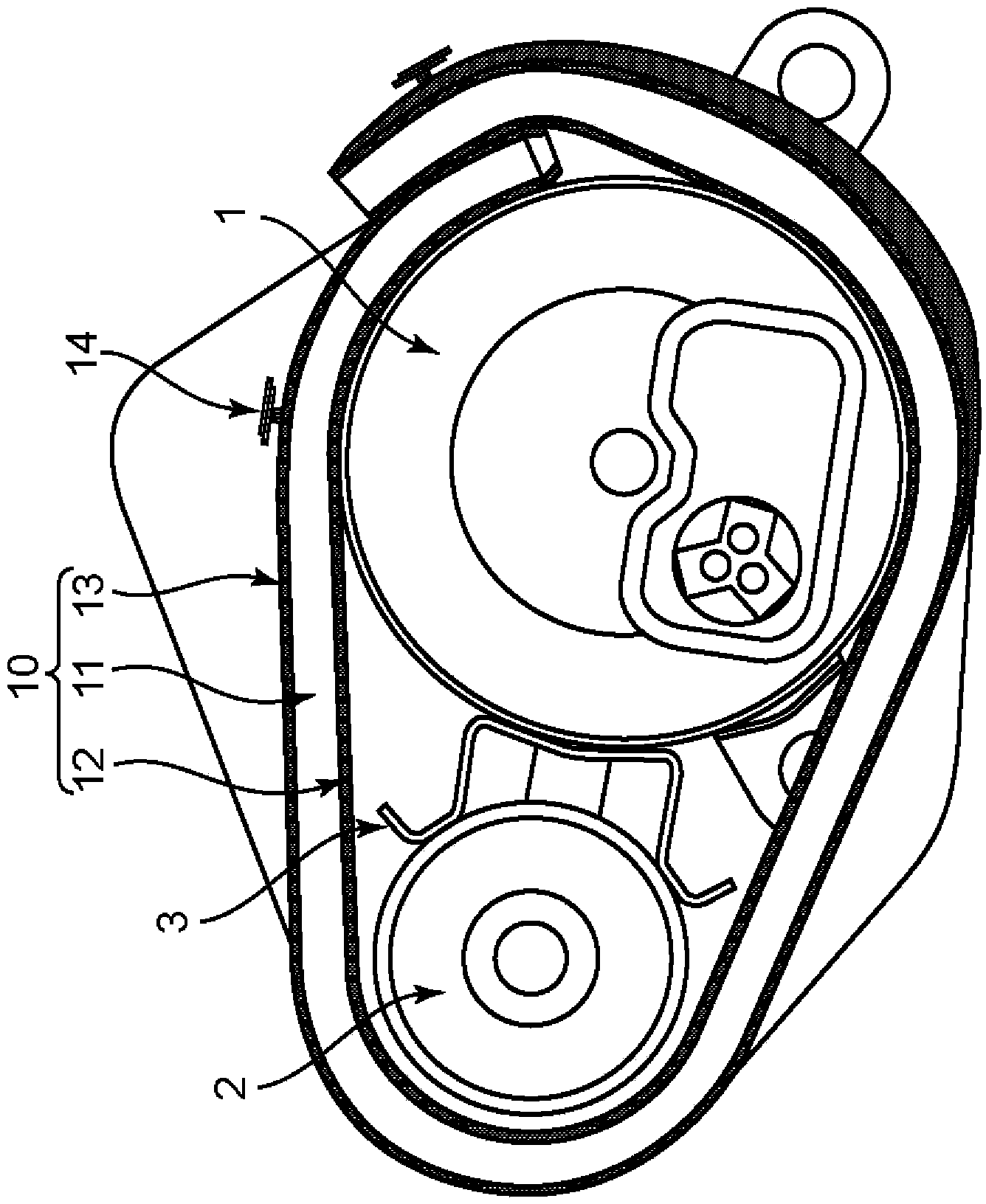

[0019] Such as figure 1 As shown, the outdoor unit of this embodiment has: a compressor 1, which is installed in the refrigerant circuit; a liquid separation reservoir 2, which is installed near the compressor 1, and serves as a low-pressure side container; and a soundproof member 10, which prevents the compressor from 1 The noise generated from the compressor 1 leaks out of the outdoor unit during operation. The outdoor unit further includes a heat exchanger for exchanging heat between the refrigerant discharged from the compressor 1 and outside air, an expansion mechanism for expanding the refrigerant condensed in the heat exchanger, a fan, a control device, and the like. However, these parts are omitted from illustration.

[0020] The compressor 1 compresses the refrigerant sucked in from the upstream side of the refrigerant circuit, turns it into high-temperature and high-pressure refrigerant, and discharges it to the downstream side of the refrigerant circuit. The compr...

no. 2 approach

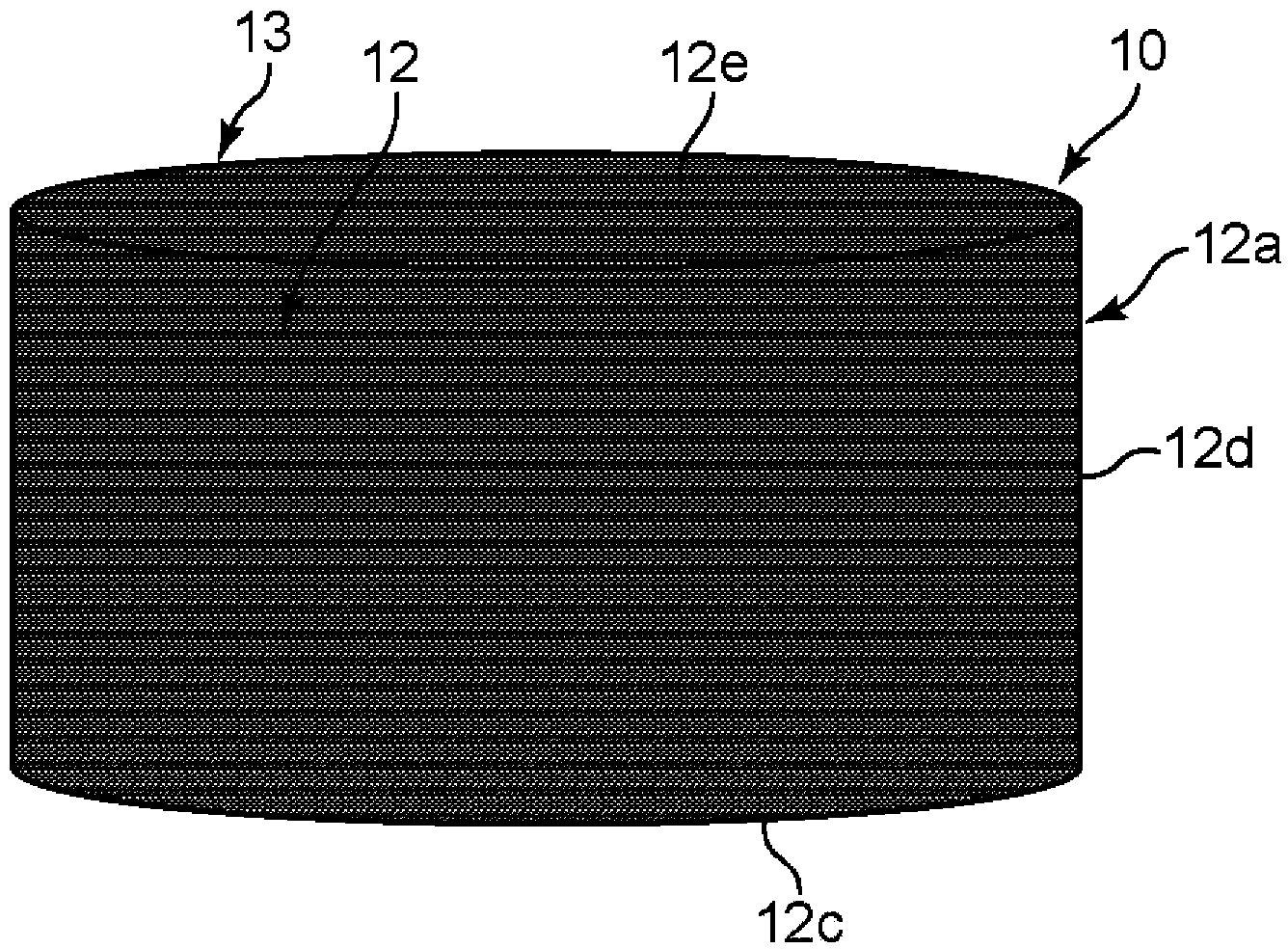

[0030] image 3 A soundproof material 10 according to a second embodiment of the present invention is shown. In addition, in the second embodiment, only the parts that are different from the first embodiment will be described, and the description of the same configuration, operation, and effect as the first embodiment will be omitted.

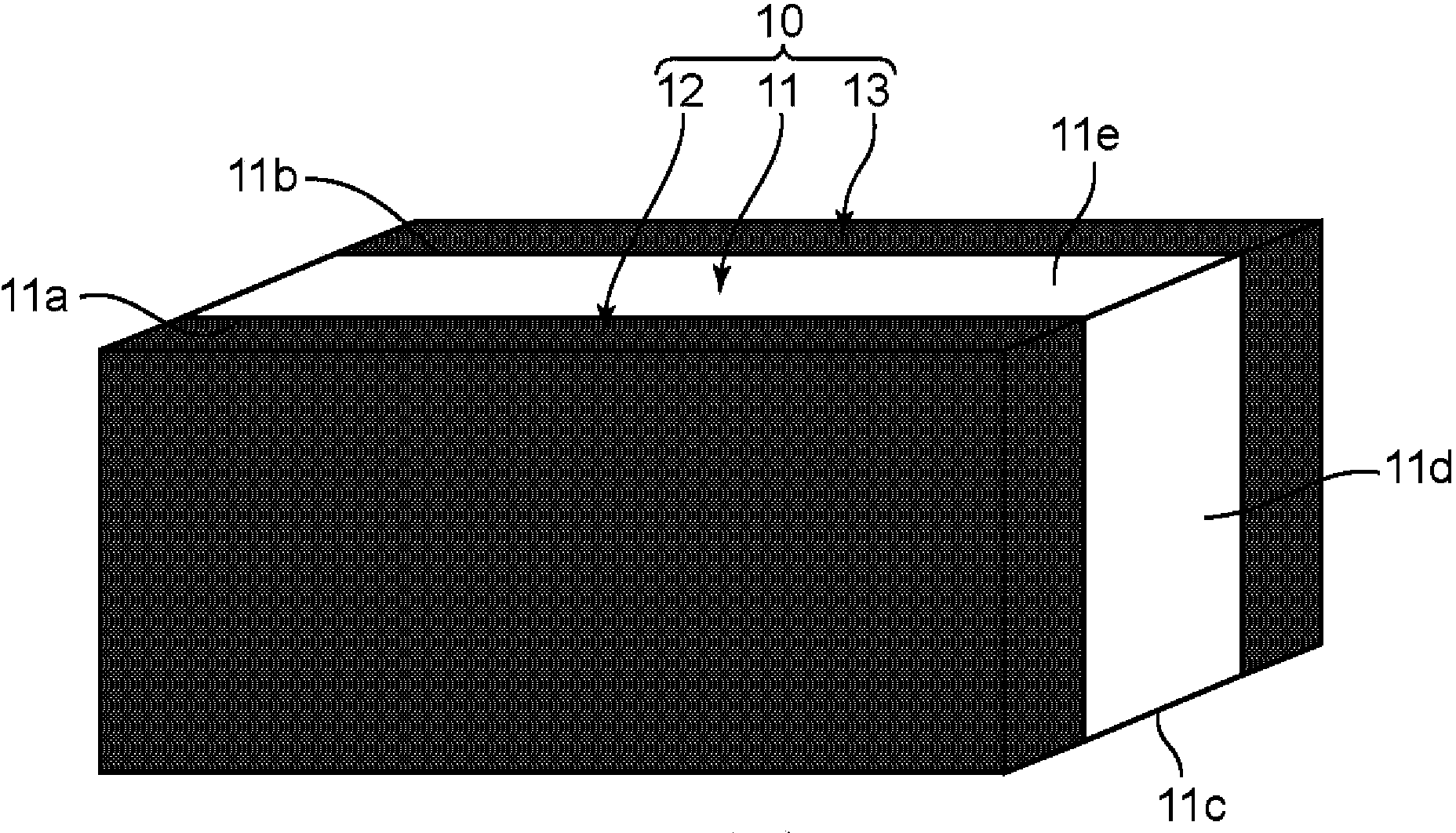

[0031] Such as image 3 As shown, the soundproof material 10 of this embodiment has the bag-shaped scattering prevention member 12a which covers all surfaces of the 1st sound absorbing material 11 using glass fiber. That is, the bag-like scattering preventing member 12a covers image 3One side main surface 11a, the other side main surface 11b, the lower surface 11c, both end surfaces 11d, 11d and the upper surface 11e of the first sound absorbing member 11 which cannot be seen in the figure. Specifically, the bag-shaped scattering preventing member 12a has a first scattering preventing member 12 covering one main surface 11a of the first sou...

no. 3 approach

[0038] In this third embodiment, only the parts that are different from those of the first embodiment will be described, and the description of the same configuration, operations, and effects as those of the first embodiment will be omitted.

[0039] In this embodiment, a sound insulating material is used as the second scattering preventing member 13 . In addition, in this embodiment, a member made of rubber is used as the sound insulating material.

[0040] As described above, in the present embodiment, the first anti-scattering member 12 is a sound absorbing material using fibers whose fiber strength is higher than that of glass fibers, the second anti-scattering member 13 is a sound insulating material, and the first anti-scattering member 12 faces the compressor. 1 is wound on the compressor 1. Therefore, among the noise generated from the compressor 1, the sound transmitted through the first scattering preventing member 12 and the first sound absorbing member 11 is refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com