Battery module

A technology for battery modules and single cells, which is applied to secondary batteries, battery temperature control, battery caps/end caps, etc., can solve problems such as no electrolyte solution, and achieve the effect of improving scattering suppression, preventing damage, and preventing scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the invention will be specifically described based on examples of the invention illustrated in the drawings.

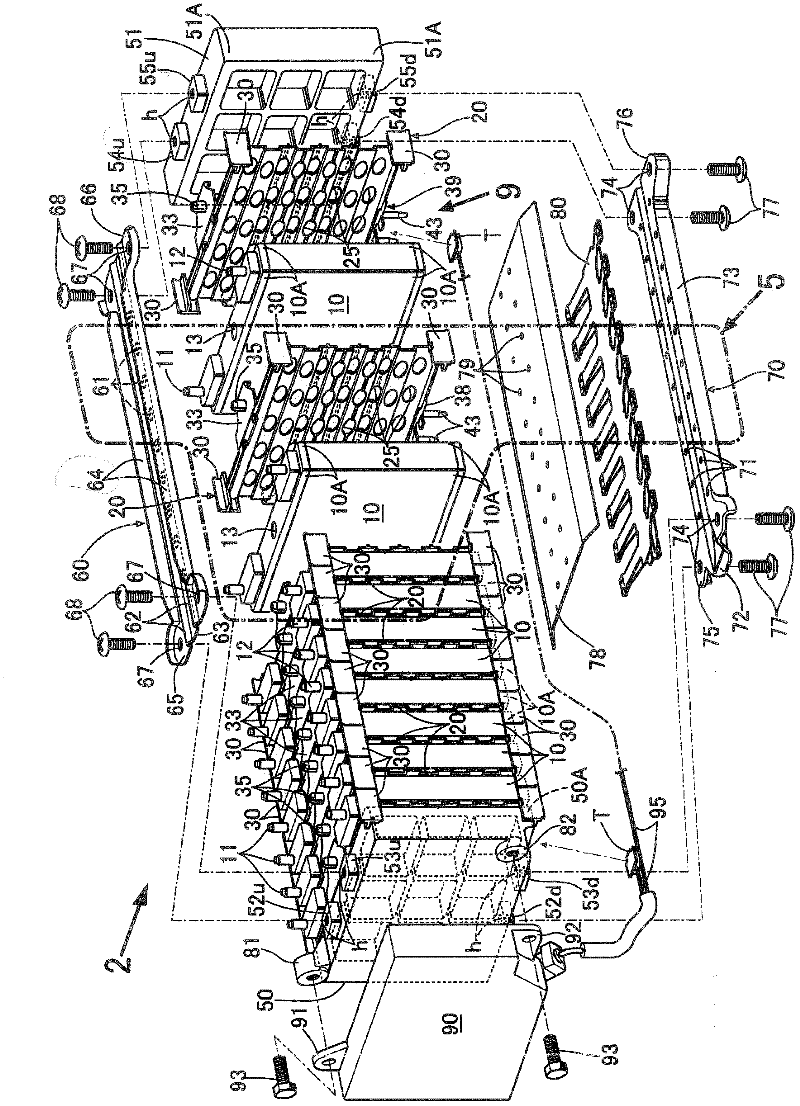

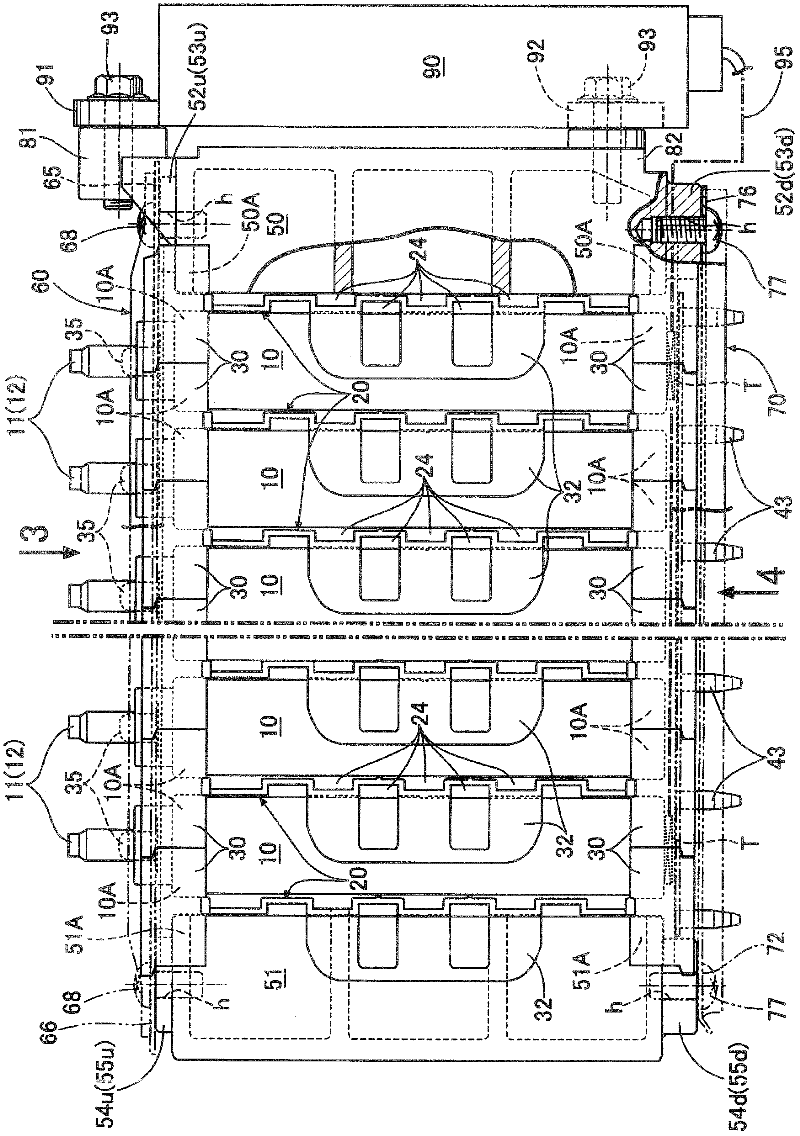

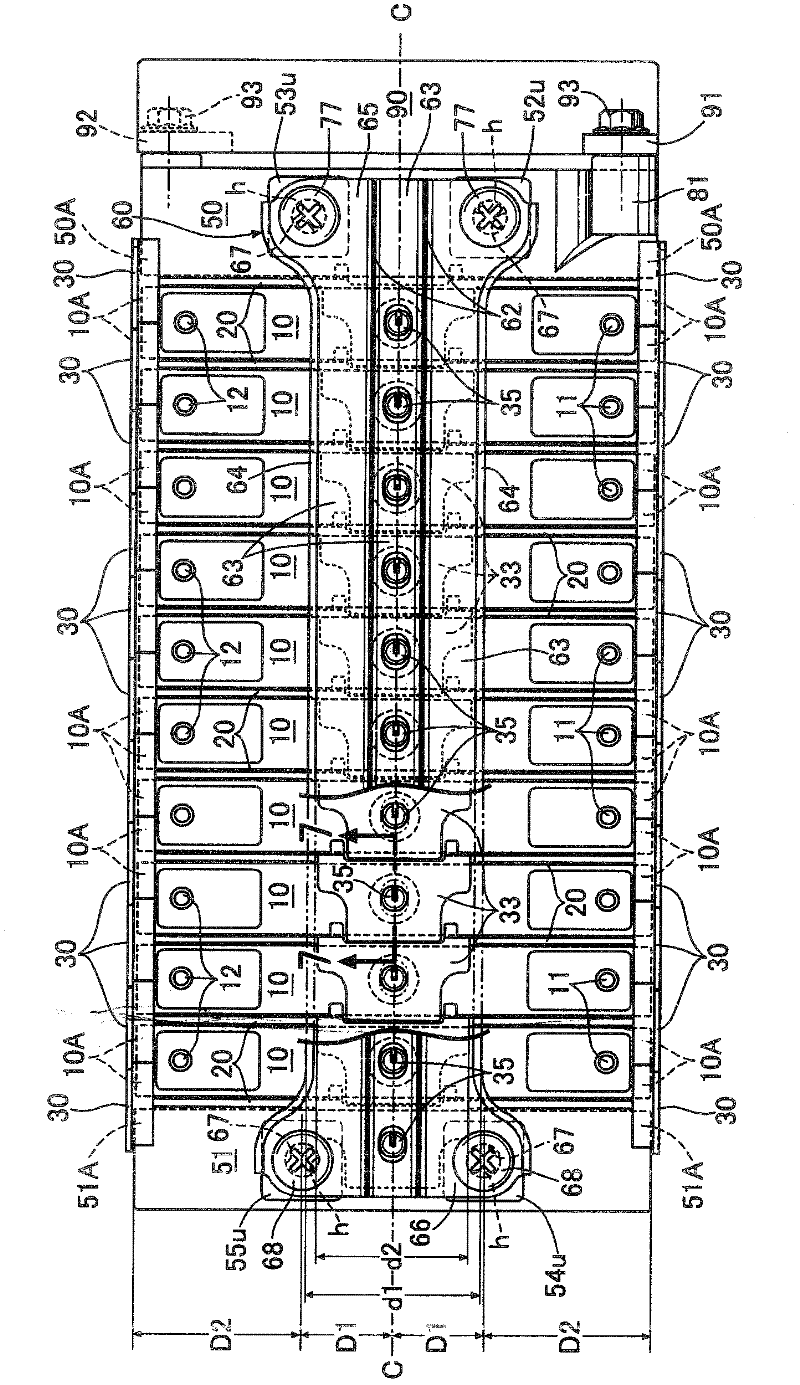

[0048] like figure 1 As shown, the battery module of the present invention includes a plurality of square cells 10 arranged side by side at intervals, a plurality of brackets 20 arranged between the cells 10 and outside the outermost cell 10 , A square-shaped end plate 50 disposed on the outside of one of the outermost brackets 20, and a square-shaped end plate (base end plate) 51 disposed on the outside of the other outermost bracket 20 are connected to each other. A plurality of single cells 10 and holders 20 stacked in close contact are clamped by a pair of end plates 50 and 51 on one side and the other side, and the end plates 50 and 51 pass through the upper connection frame 60 and the lower connection frame as connection members. 70 and fastened into one. Furthermore, a voltage sensor assembly 90 (voltage sensor) is coupled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com