Light-emitting device, electronic apparatus, and film-forming method

A technology of light-emitting device and film-forming method, which is applied in the direction of circuits, electrical components, electric solid devices, etc., to achieve the effect of stable potential and stable current control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

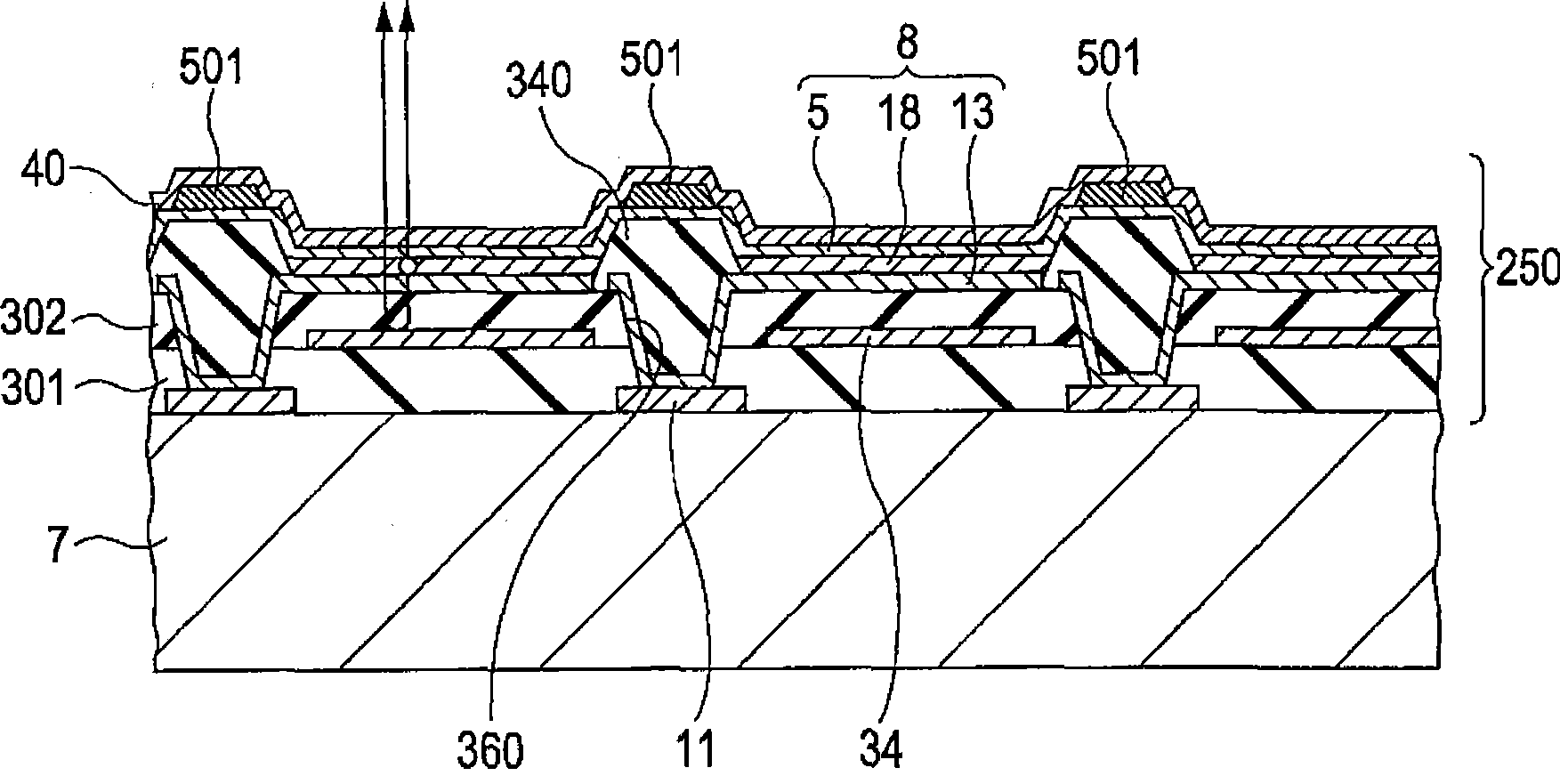

[0129] Auxiliary electrode width W=30μm

[0130] The thickness of the auxiliary electrode T = 310nm

[0131] Angle θ = 45 degrees for the conical shape

[0132] Auxiliary electrode material = aluminum

[0133] Thickness T1 of the barrier layer 40 = 200 nm

[0134] Material of barrier layer 40 = SiON

Embodiment 2

[0136] Auxiliary electrode width W=30μm

[0137] The thickness of the auxiliary electrode T = 200nm

[0138] Angle θ = 30 degrees for the conical shape

[0139] Auxiliary electrode material = silver

[0140] Thickness T1 of the barrier layer 40 = 200 nm

[0141] Material of barrier layer 40 = SiON

[0142] In the above-mentioned embodiments, the reason why the thickness of the auxiliary electrode can be reduced in the second embodiment compared with the first embodiment is that the resistance value of "silver" is smaller than that of "aluminum". In addition, the reason why the second embodiment can reduce the angle θ compared with the first embodiment is also for the same reason.

[0143] In any case, according to the above-mentioned Examples 1 and 2, it was confirmed that the effect according to the above-mentioned present embodiment is effectively exhibited.

[0144] A method of manufacturing the above-mentioned organic EL device, particularly a method of forming a film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com