A kind of preparation method of copper chromium alloy surface superhard coating

A copper-chromium alloy and hard coating technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of easy failure, easy surface wear, poor resistance to arc ablation, etc., to improve surface performance, good focus Sex, small heat affected area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

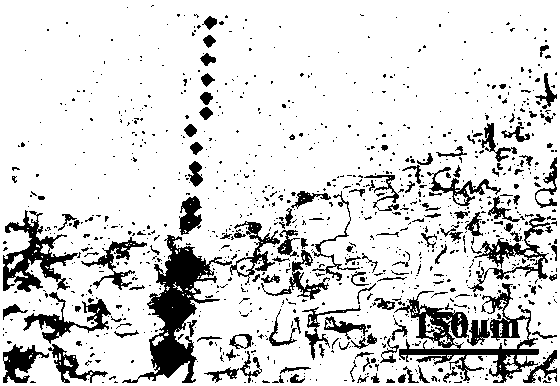

Embodiment 1

[0027] The CuCr25 alloy with a Cr wt.% content of 25 wt.% was prepared by vacuum induction melting, and machined into a round alloy sample with a diameter of 30 mm and a height of 5 mm. The sample was polished with sandpaper, and then the CuCr25 sample was placed in the Wash it in an ultrasonic cleaning machine with alcohol for 8 minutes; then clean it with water and alcohol in turn, and dry it with a hair dryer after cleaning. Dissolve a small amount of polyvinyl alcohol particles in 100 ml of boiling water to prepare an aqueous solution of polyvinyl alcohol as a binder. The Co-based composite powder with a W content of 8wt.% was uniformly mixed with a binder to form a paste, which was then coated on the surface of a clean CuCr25 alloy block, and then dried at 80 °C for 3 h. Place the dried sample on the stage of the laser equipment, start the Nd:YAG pulsed laser equipment for overlapping scanning, the overlapping rate is 30%, the main parameters of the laser surface strength...

Embodiment 2

[0031] The CuCr25 alloy with a Cr wt.% content of 25 wt.% was prepared by vacuum induction melting, and machined into a round alloy sample with a diameter of 30 mm and a height of 5 mm. The sample was polished with sandpaper, and then the CuCr25 sample was placed in the Clean it in an ultrasonic cleaning machine with alcohol for 10 minutes; then clean it with water and alcohol in turn, and dry it with a hair dryer after cleaning. Dissolve a small amount of polyvinyl alcohol particles in 100 ml of boiling water to prepare an aqueous solution of polyvinyl alcohol as a binder. The Co-based composite powder with a W content of 10wt.% was uniformly mixed with a binder to form a paste, which was then applied on the surface of a clean CuCr25 alloy block, and then dried at 80 °C for 3 h. Place the dried sample on the stage of the laser equipment, start the Nd:YAG pulsed laser equipment for lap scanning, the lap rate is 30%, the main parameters of the laser surface strengthening treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com