A process method for increasing the thickness of laser cladding high-hardness alloy layer and its laser cladding repair product

A technology of laser cladding and process method, applied in the direction of metal material coating process and coating, can solve the problems of increasing alloy layer, increasing equipment and time cost, increasing process steps, etc., to increase the thickness of alloy layer without heat preservation Process, the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The process method for increasing the thickness of the laser cladding high-hardness alloy layer in this embodiment includes the following steps:

[0035] S1. According to the number of cladding layers and cladding thickness of the substrate material to be cladding, by means of finite element software model analysis, determine the stress distribution state of the alloy layer;

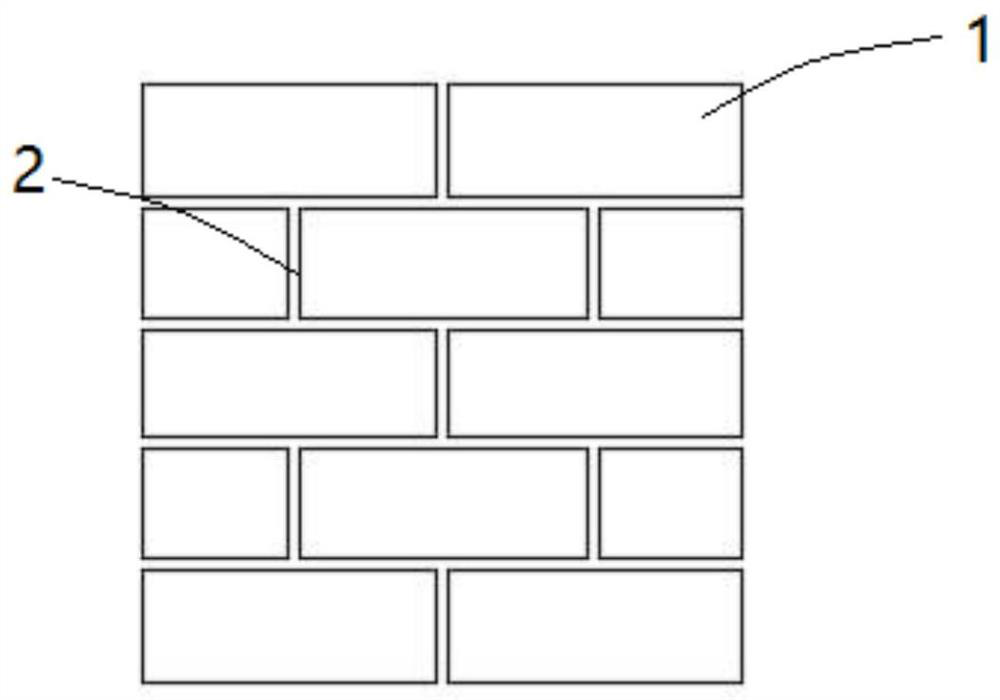

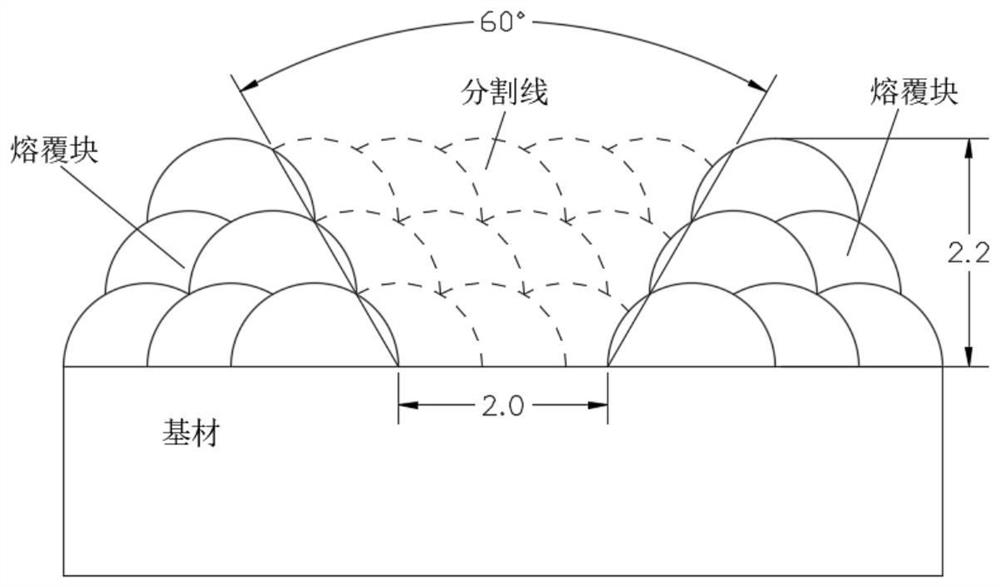

[0036] S2. Divide the cladding area of the substrate material according to the stress distribution state, determine the position and size of the cutting line; form a cladding block on the surface of the substrate material;

[0037] S3. Determine the cladding process;

[0038] S4. According to the cladding process in step S3, block cladding is performed first, and then the cutting line is clad and filled to complete the alloy layer cladding meeting the technical requirements.

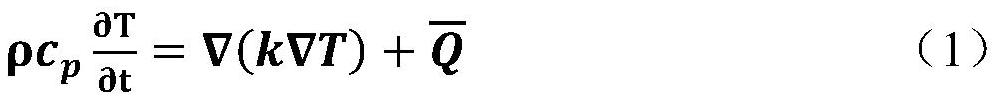

[0039] Wherein, finite element analysis is carried out by thermodynamics sysweld simulation software, and finite elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com