Binder particles for electrochemical element

A technology for electrochemical components and adhesives, applied in electrical components, electrochemical generators, circuits, etc., can solve problems affecting the performance of electrochemical components, and achieve the effect of excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

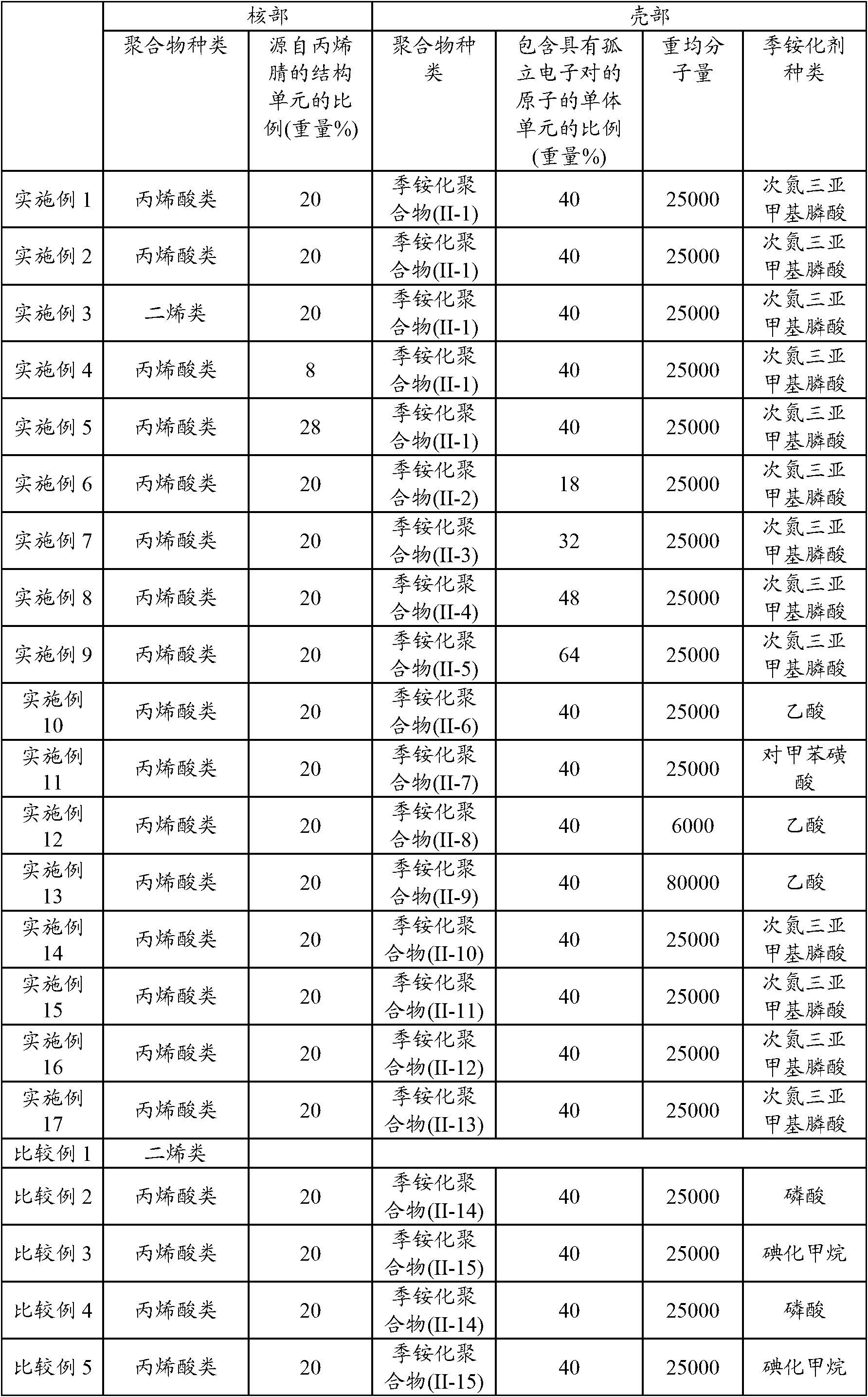

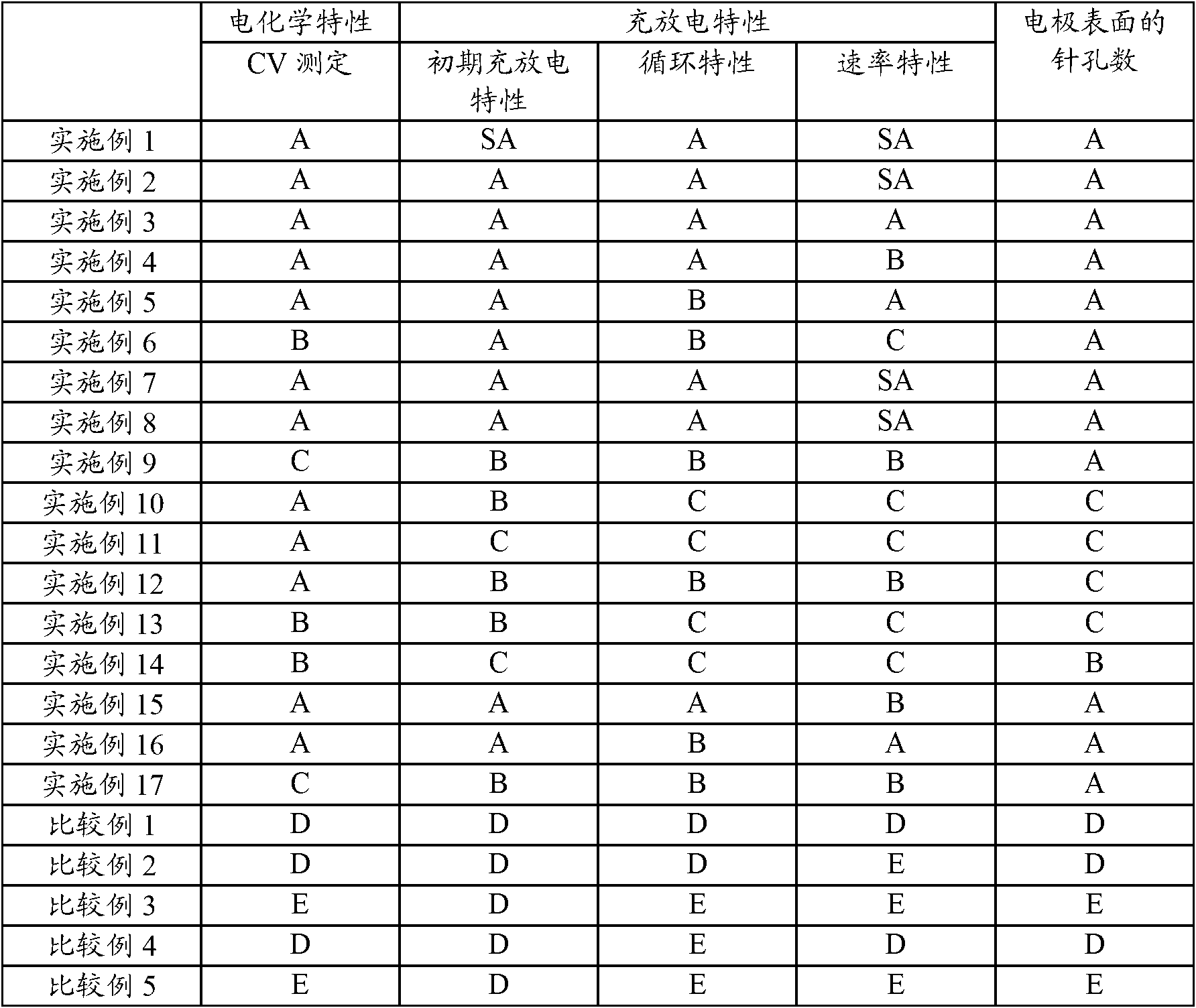

Embodiment 1

[0212] Charge 40 parts of methyl ethyl ketone into the reactor and raise the temperature to 120°C under nitrogen atmosphere, 3.0 parts of p-azobisisobutyronitrile, 60 parts of dimethylaminoethyl methacrylate, 70 parts of butyl acrylate, 20 parts of methyl methacrylates were mixed, and the obtained mixed solution was added dropwise at a constant rate over 3 hours, and further reacted for 3 hours to prepare a polymer (I-1). Then the produced polymer (I-1) was cooled to 60° C., and 145 parts of nitrilotrimethylene phosphonic acid (relative to the mole of nitrogen atom in dimethylaminoethyl methacrylate) was added as a quaternizing agent The number is 1 mole) and 500 parts of ion-exchanged water to prepare a quaternized polymer (II-1). The weight average molecular weight of the quaternized polymer (II-1) was 25,000. In addition, the content of the monomer (dimethylaminoethyl methacrylate) unit containing an atom having a lone electron pair in the quaternized polymer (II-1) was 40...

Embodiment 2

[0223] As the negative electrode active material, lithium titanate (Li 4 Ti 5 o 12 ) instead of artificial graphite, except that, the same operation as in Example 1 was performed to prepare and evaluate an emulsion of binder particles with a core-shell structure, a slurry for electrodes, an electrode, and a coin-shaped lithium ion secondary battery. The results are shown in Table 1 and Table 2.

Embodiment 3

[0225] The temperature of the quaternized polymer (II-1) obtained in Example 1 was raised to 50°C, and a mixture of 80 parts of butadiene, 40 parts of styrene and 30 parts of acrylonitrile, 0.3 parts of potassium persulfate and ion-exchanged water 50 parts were added dropwise at a constant speed for 4 hours at the same time, and then allowed to react for 6 hours to obtain the quaternized polymer (II-1) as the shell portion and the styrene / butadiene / acrylonitrile copolymer ( Elastomeric polymer) as a dispersion of core-shell adhesive particles at the core. The obtained dispersion was concentrated to obtain an emulsion of binder particles having a solid content concentration of 40%. Except having used this as a binder particle emulsion, the same operation as Example 1 was performed, the slurry for electrodes, an electrode, and a coin-type lithium ion secondary battery were produced and evaluated. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com