Valve and processing device with the valve

An exhaust device and valve body technology, applied in valve devices, sliding valves, valve details, etc., can solve the problems of decreased processing capacity, high cost of sealing components, increased manufacturing cost and maintenance cost of gate valves, etc., and achieves reduction of maintenance costs. , low cost, low manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

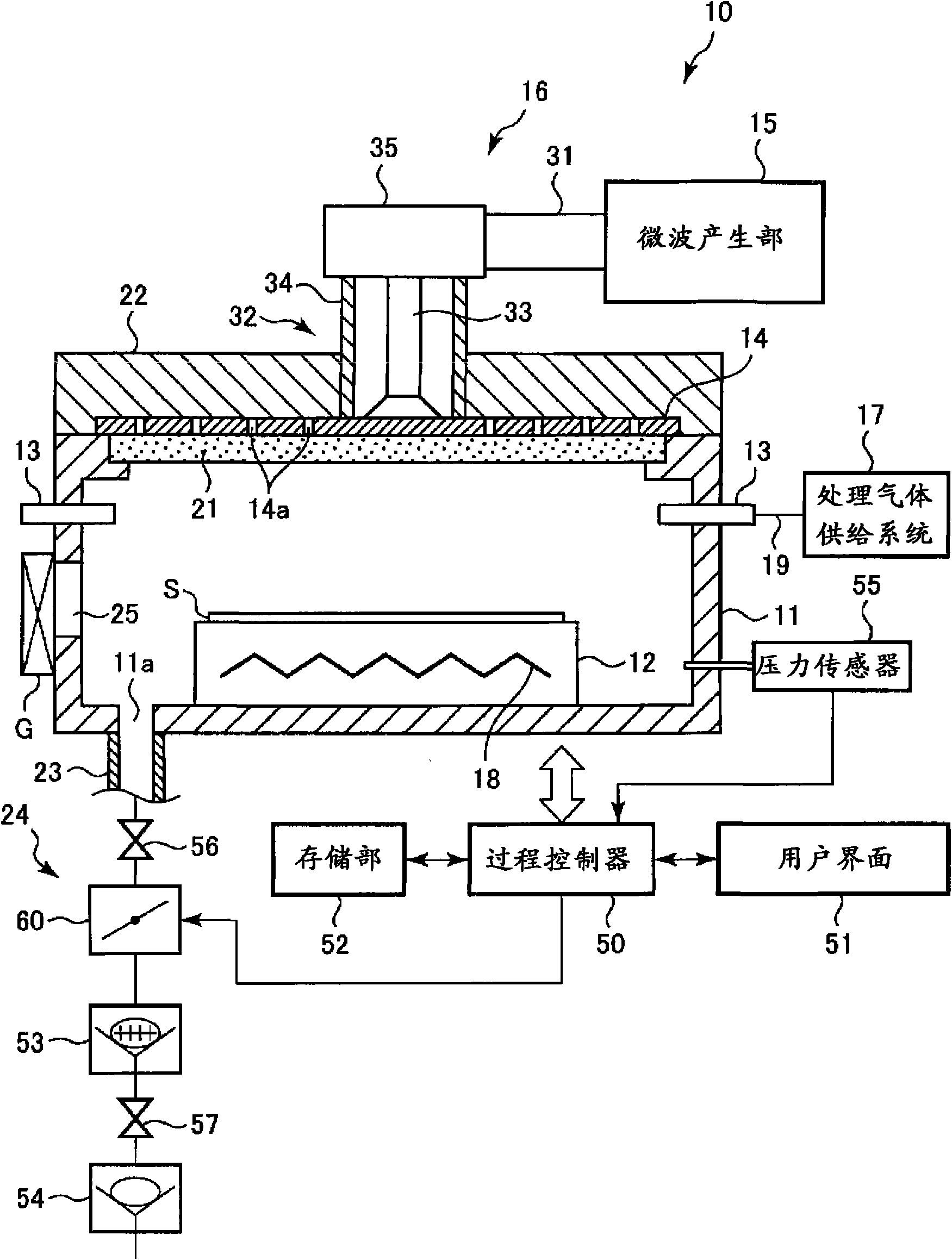

[0076] figure 1 It is a schematic cross-sectional view of an RLSA microwave plasma processing apparatus using the pressure control valve according to the first embodiment of the present invention.

[0077] Such as figure 1 As shown, the RLSA microwave plasma processing device 10 has: a substantially cylindrical cavity 11 for accommodating a semiconductor substrate and maintaining a vacuum; The side wall of 11 is used to introduce the gas introduction part 13 that forms the annular shape of processing gas; It is arranged facing the opening of the upper part of cavity 11, and is formed with the planar antenna 14 of a plurality of microwave penetration holes 14a; The microwave that produces microwave the microwave generating unit 15 ; the microwave transmission mechanism 16 guiding the microwave generating unit 15 to the planar antenna 14 ; and the processing gas supply system 17 supplying the processing gas to the gas introducing unit 13 .

[0078] Below the planar antenna 14,...

no. 2 approach

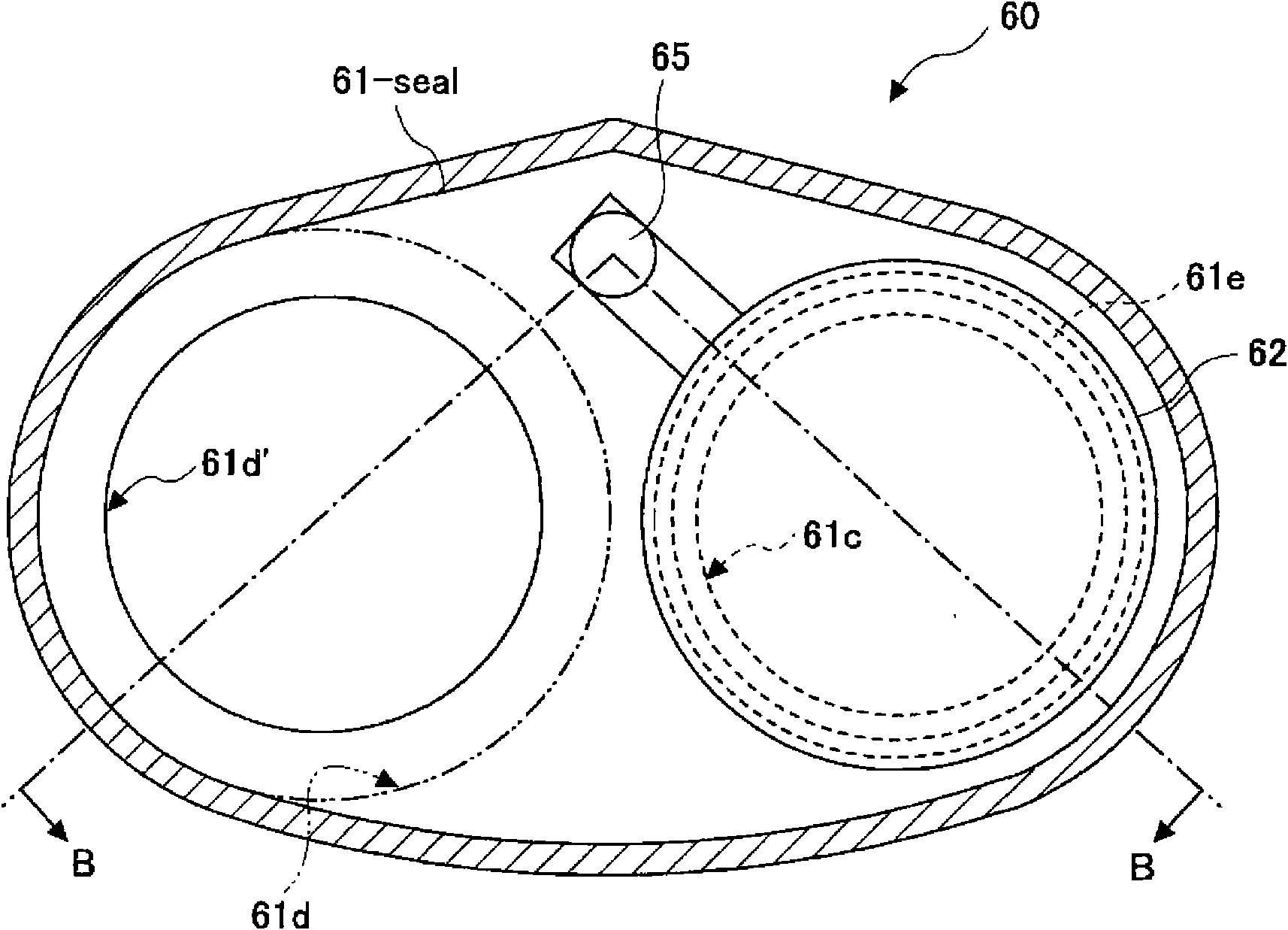

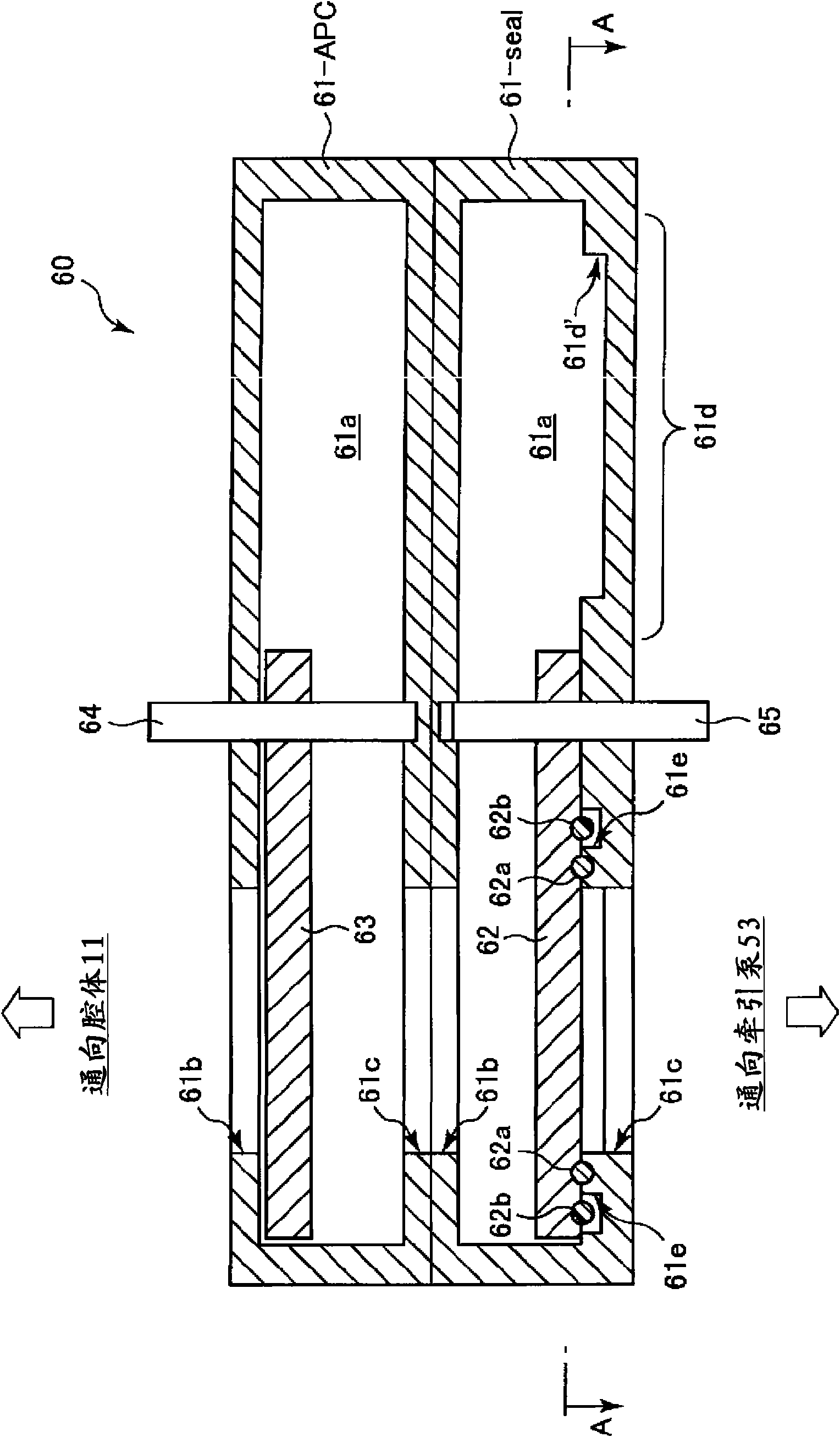

[0112] Figure 7 It is a sectional view showing the structure of the pressure control valve 60 of the second embodiment. Figure 7 The cross-section shown, for example, is the same as that showing the state where the opening is closed by the closing valve body. figure 2 corresponding to the B-B profile.

[0113] Such as Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the rotation shaft 64 and the rotation shaft 65 are coaxial.

[0114] In the pressure control valve 60 of the second embodiment, the part for controlling the pressure is also of the pendulum type like the part for closing. The control valve body 63 is attached to the rotation shaft 64, and rotates around the central axis of the rotation shaft 64 between the opening 61b of the valve main body 61-APC and the space 61a.

[0115] The closing valve body 62 is attached to the rotation shaft 65 . The rotating shaft 65 is formed as a hollow shaft having a hollow port...

Embodiment approach 1

[0118] At this time, even when the rotating shaft 64 and the rotating shaft 65 are coaxial during periodic inspection, inspection and repair can be performed only by removing the valve main body 61-APC or the valve main body 61-seal. Therefore, as in the first embodiment, maintenance of the processing apparatus can be simplified and maintenance costs can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com