Non-uniform distribution preload controllable high-speed spindle based on piezoelectric actuator and its control method

A piezoelectric actuator, non-uniform distribution technology, applied in rolling contact bearings, shafts, bearings, etc. Uniform distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

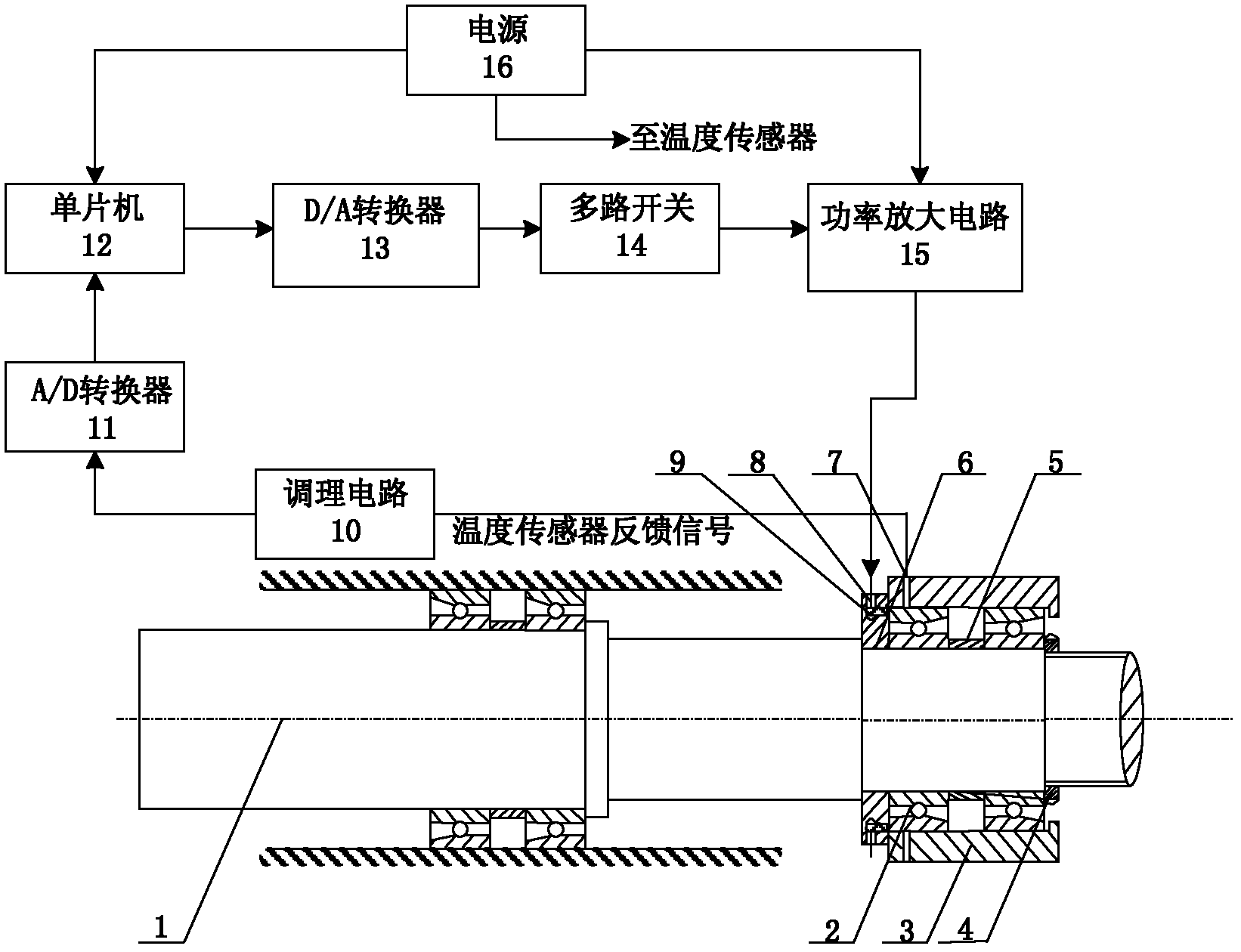

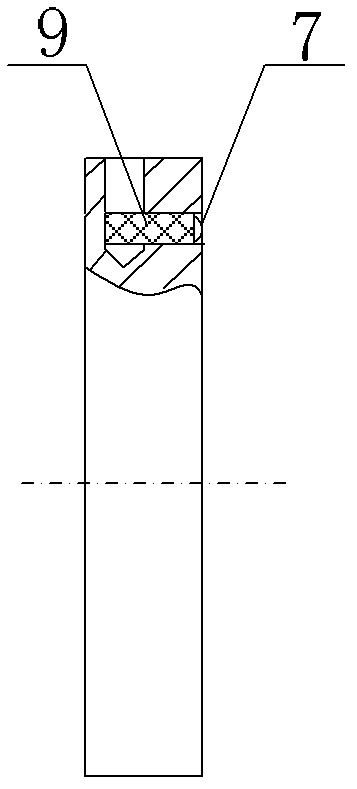

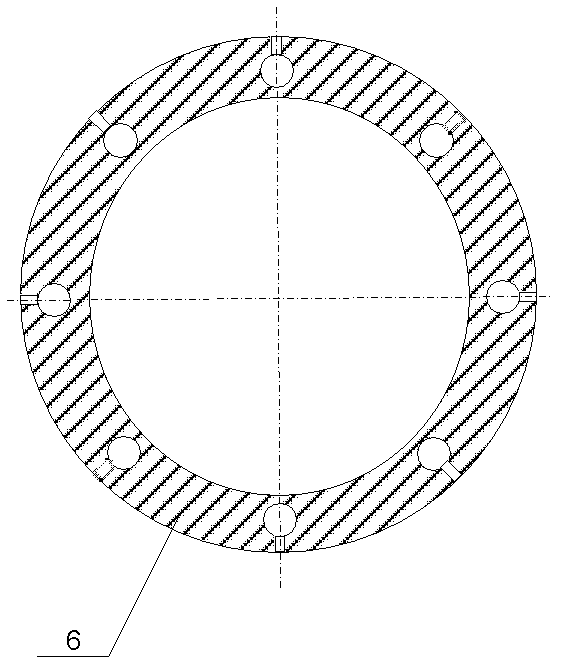

[0016] The following is a specific introduction to the piezoelectric actuator-based non-uniformly distributed preload controllable high-speed spindle and its control method in conjunction with the accompanying drawings:

[0017] see figure 1 As shown, the present invention is based on the controllable high-speed spindle of the non-uniformly distributed pretightening force based on the piezoelectric actuator, including the spindle 1, the bearing 2, the bearing support 3, the round nut 4, the sleeve 5, the pretightening ring 6, the temperature Sensor 7, piezoelectric actuator control line 8, piezoelectric actuator 9, conditioning circuit 10, A / D converter 11, single-chip microcomputer 12, D / A converter 13, multi-way switch 14, power amplifier circuit 15, power supply16. Wherein, the pre-tightening ferrule 6, temperature sensor 7, piezoelectric actuator control line 8, piezoelectric actuator 9, conditioning circuit 10, A / D converter 11, single-chip microcomputer 12, D / A converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com