Sewing machine

A sewing machine and sewing needle technology, which is applied to sewing machine components, sewing machine needle seats, sewing equipment, etc., can solve the problems that the sewing speed cannot be increased, the needle bar table is heavy, and the needle bar is difficult to achieve high speed, etc., to achieve Ease of high-speed rotation, high speed, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach ]

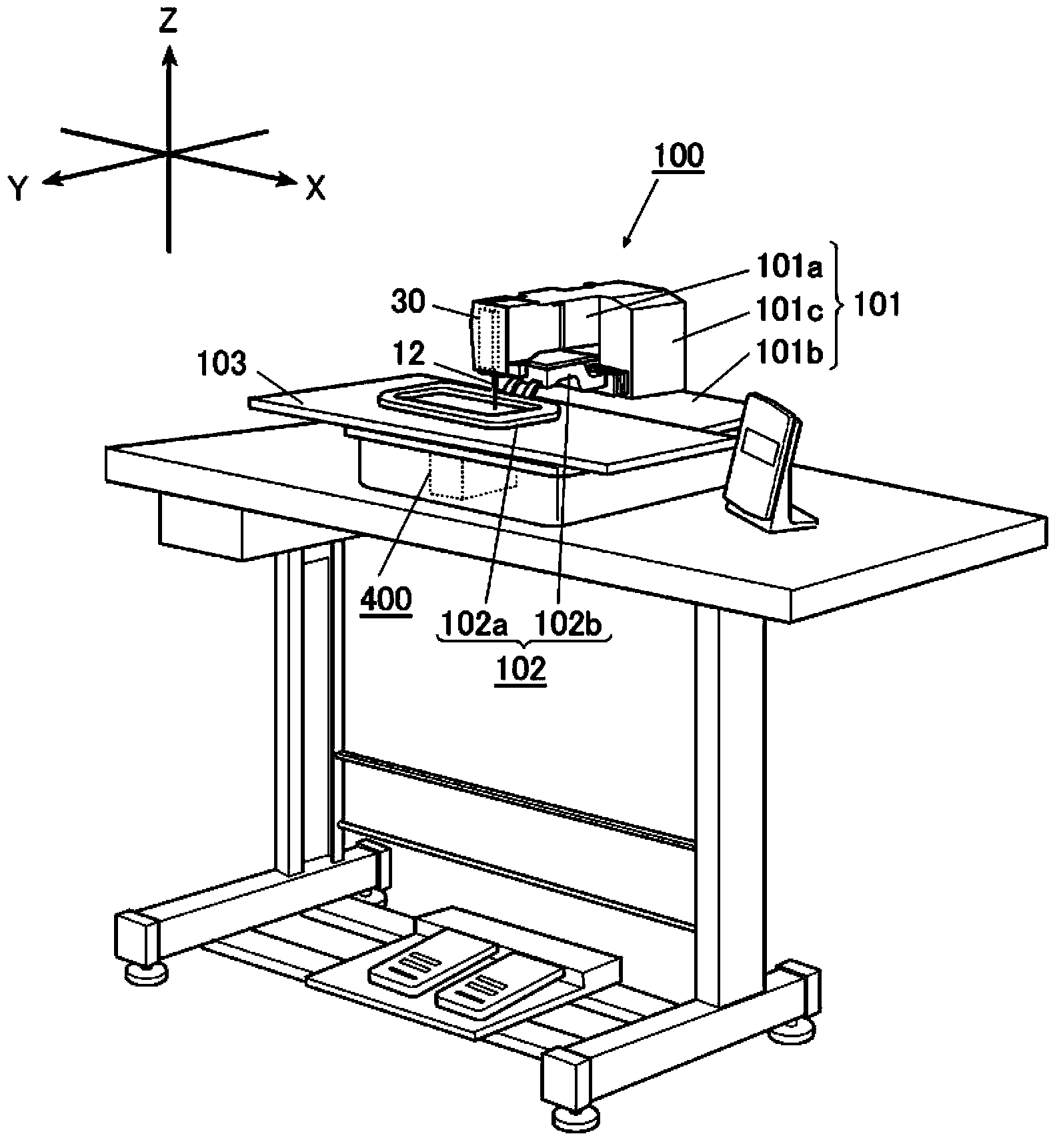

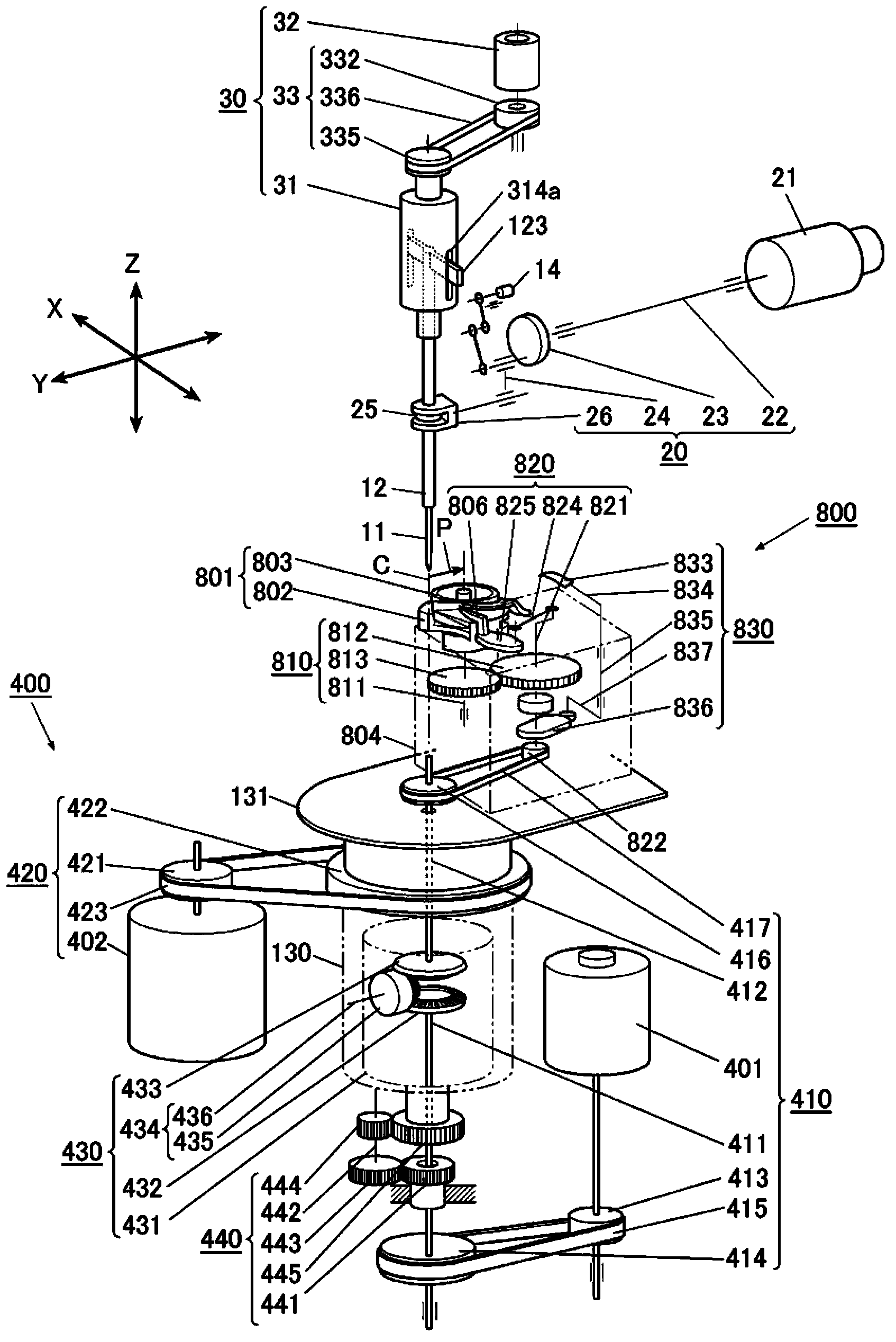

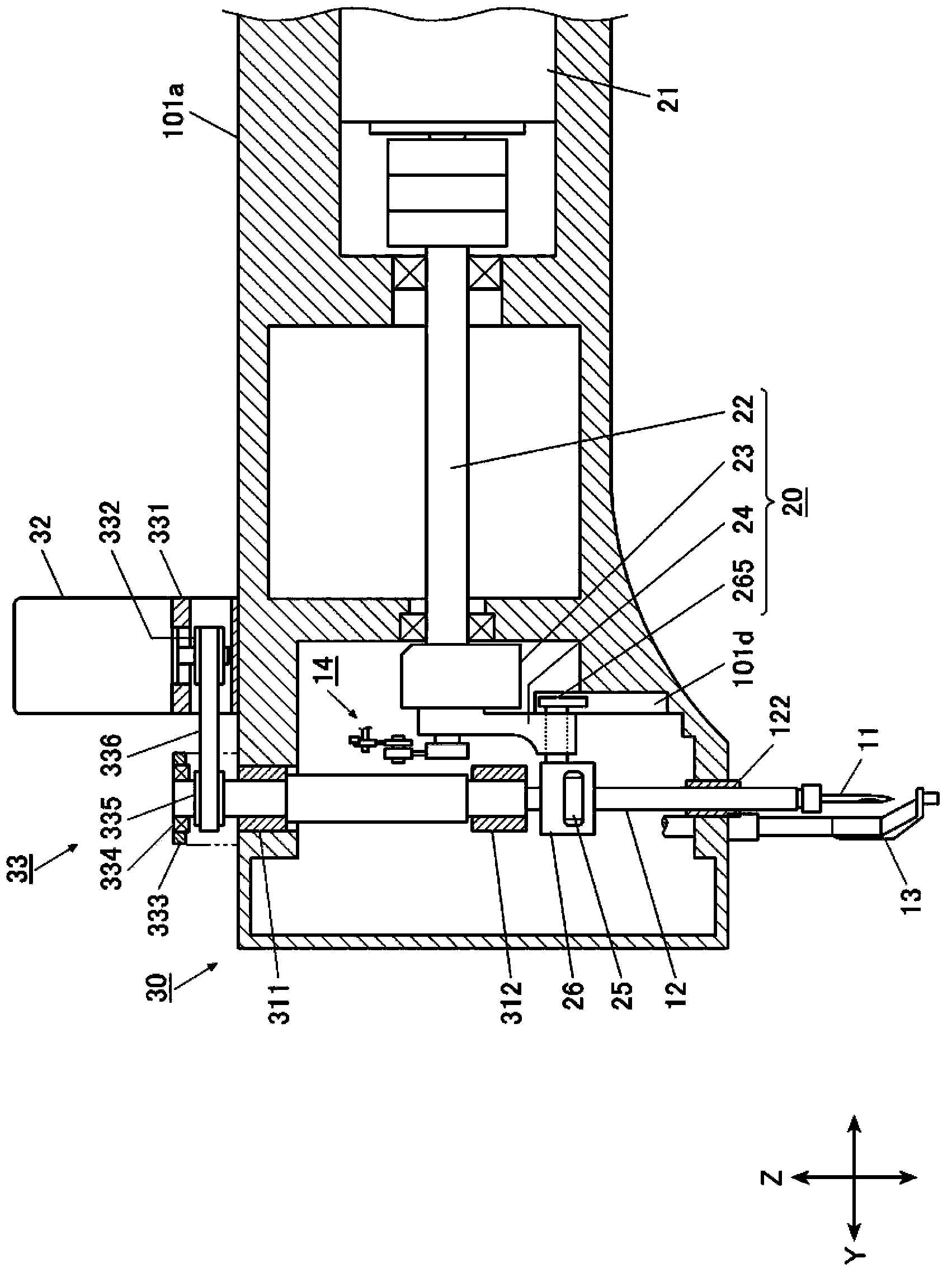

[0279] As the second embodiment of the present invention, based on Figure 22 ~ Figure 31 , a sewing machine 100A using a cutter needle having a needle drop hole of a unique shape as a sewing needle will be described.

[0280] exist Figure 22 Among them, the sewing machine 100A is different from the above-mentioned sewing machine 100 in that the lower end of the needle bar 12 has a flat cutting knife needle 11A and a needle bar thread guide 154A for the knife needle. In addition, the control device 110 of the sewing machine 100A (see Figure 14 ) is characterized in that the inherent sewing operation control is performed on the cutter needle 11A described later.

[0281] In addition, the structure of this sewing machine 100A other than the above is the same as that of the sewing machine 100 . In the following description, differences between the sewing machine 100A and the sewing machine 100 will be mainly described.

[0282] The above-mentioned sewing machine 100A is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com