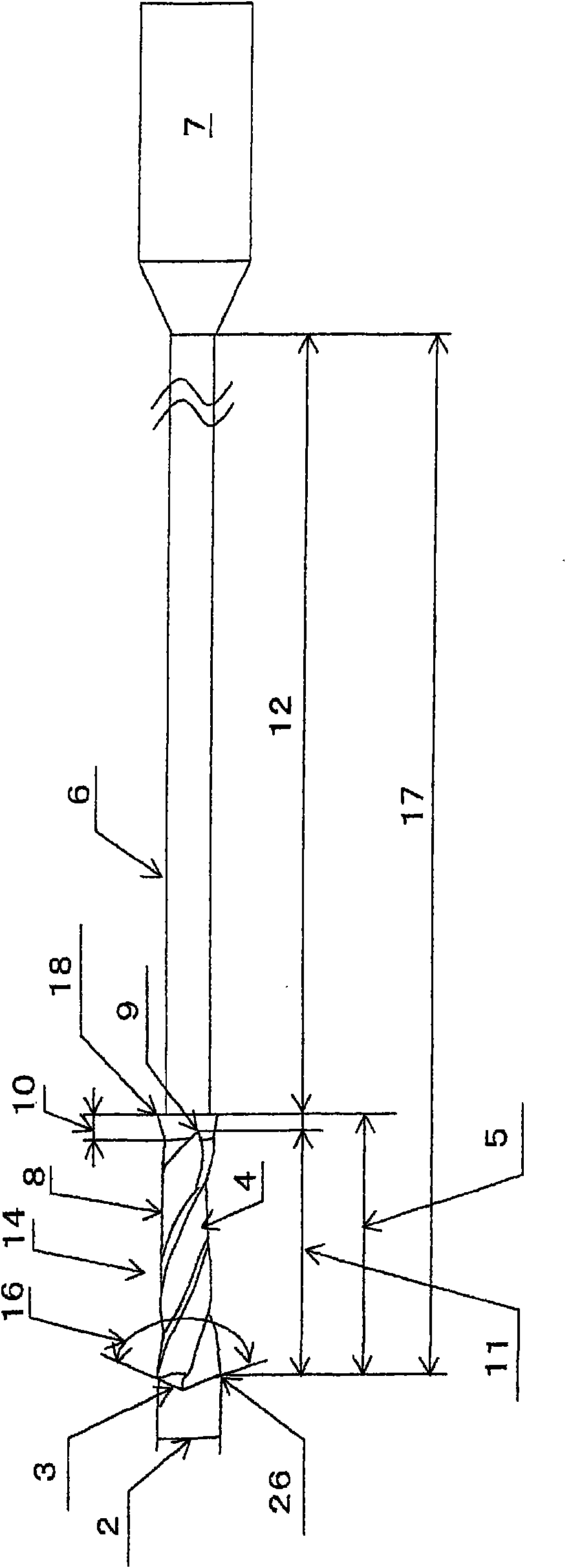

Small-diameter deep hole drill and fine deep hole processing method

A processing method and small-diameter technology, applied in boring/drilling, drilling/drilling equipment, metal processing, etc., can solve the problems of inability to process deep holes, breakage of small-diameter drills, and deterioration of hole straightness, etc. problems, to achieve the effect of good flatness, improved inner surface roughness, and excellent flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

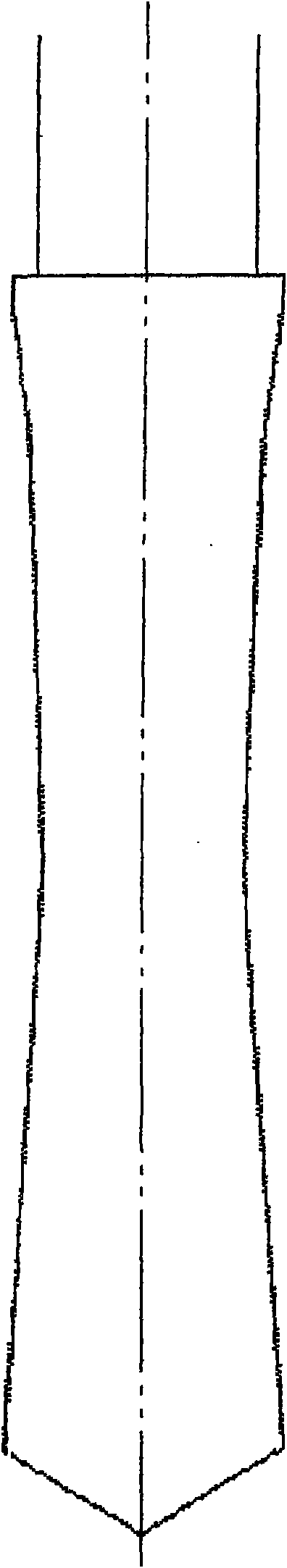

[0207] As an example of the present invention and a comparative example, a drill with 2 flutes, a drill diameter of 0.2 mm, a groove twist angle of 30 degrees, a web thickness of 0.07 mm (35% of the drill diameter), a shank diameter of 3 mm, and a drill head of 5 For a drill with a length of 1.1mm, the groove length, the reduction of the outer diameter (the amount of reverse taper), the outer diameter of the end of the groove, and the maximum diameter of the tapered diameter expansion part arranged in a straight line, etc., were produced as shown in Table 1. Several kinds. In Table 1, the length of the groove, the outer diameter of the end of the groove, and the maximum diameter of the tapered diameter-enlarged portion arranged in a straight line represent magnifications corresponding to the diameter of the drill. The base material of the drill bit is an ultrafine particle cemented carbide with an average particle size of WC of 0.6 μm or less and a Co content of 13w%, and AlCr...

Embodiment 2

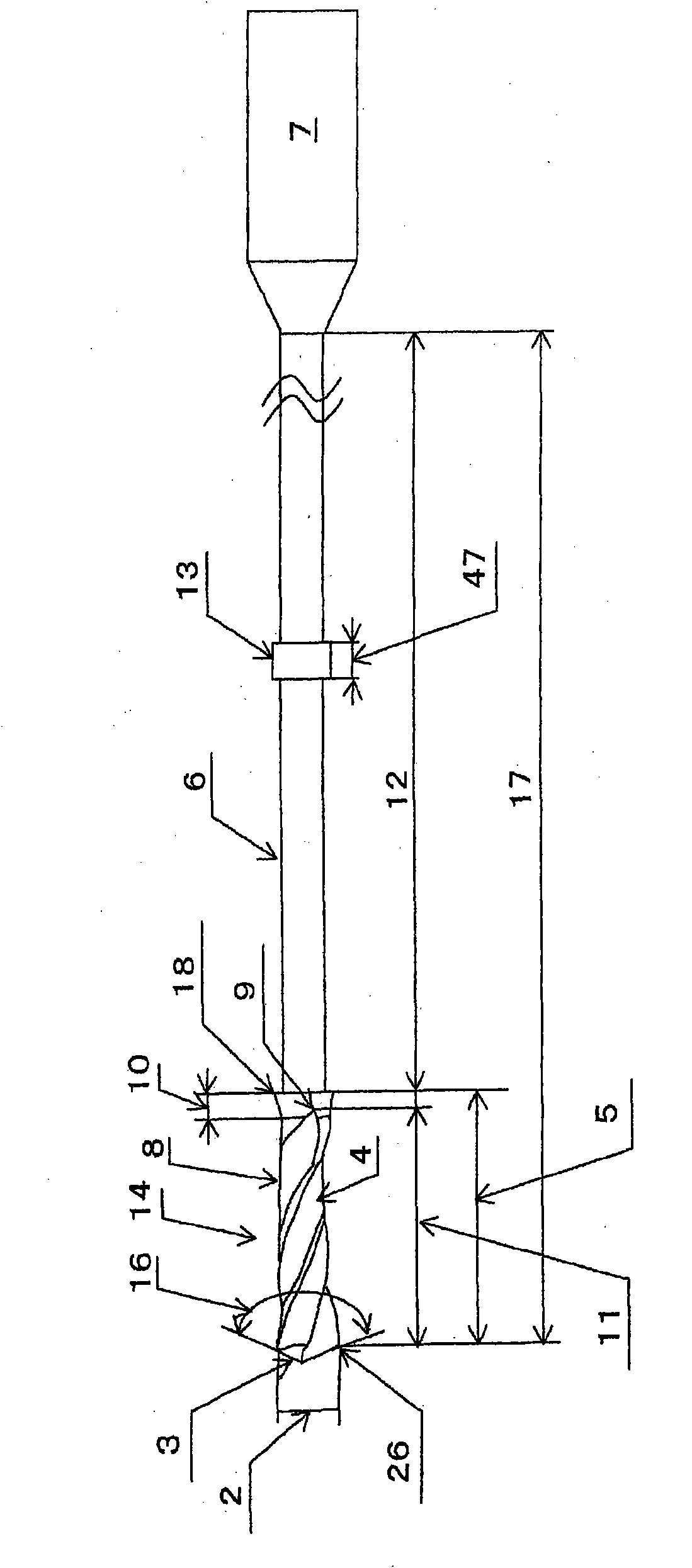

[0215] As an example of the present invention and a comparative example, two flutes, a drill diameter of 0.2 mm, a drill head of 1.1 mm, a neck length of 9.0 mm, a total length of 40 mm, a groove twist angle of 30 degrees, and a web thickness of 0.07 mm (35% of the drill diameter), the diameter of the shank is 3 mm, and the guide is set at a position 2.0 mm away from the cutting edge of the neck. Several types are produced as shown in Table 1, such as the reduced diameter of the diameter (the amount of reverse taper), the outer diameter of the groove end, and the maximum diameter of the tapered enlarged diameter part arranged in a straight line. The base material of the drill bit is an ultrafine particle cemented carbide with an average particle size of WC of 0.6 μm or less and a Co content of 13w%, and AlCrN films are coated on the drill head and neck.

[0216] The test conditions are as follows: a rectangular block material of SUS304 is prepared as the material to be cut, an...

Embodiment 3

[0224]Next, a sample having a neck length of 15 mm, a total length of 50 mm, and a change in the interval between the guide portions was produced with the same specifications as in Example B5 of the present invention. The test conditions are: the depth of the processed hole is 10mm (80 times the diameter of the drill bit) of the through hole, and the others are the same as in Example 2. Evaluation was the same as in Example 2. The results are shown in Table 3.

[0225] 【table 3】

[0226]

[0227] As a result, due to the effect of the guides provided on the neck, Inventive Examples B30 to B32 having guides at intervals of 1.0 mm to 2.0 mm can process holes with good straightness of 10 μm or less.

[0228] On the contrary, in Comparative Example B33 and Comparative Example B34, sufficient flatness could not be obtained. It is estimated that this may be due to the small interval between the guide parts, which partially increases the cutting resistance, and the flatness cann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com