Cutter rod rack arranged on facing head and used for clamping cutter rod in double directions

A technology of flat rotating disk and tool holder, which is applied in the field of tool holder, which can solve the problems of time-consuming and laborious replacement of the holder, and achieve the effects of saving replacement time, improving stability, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

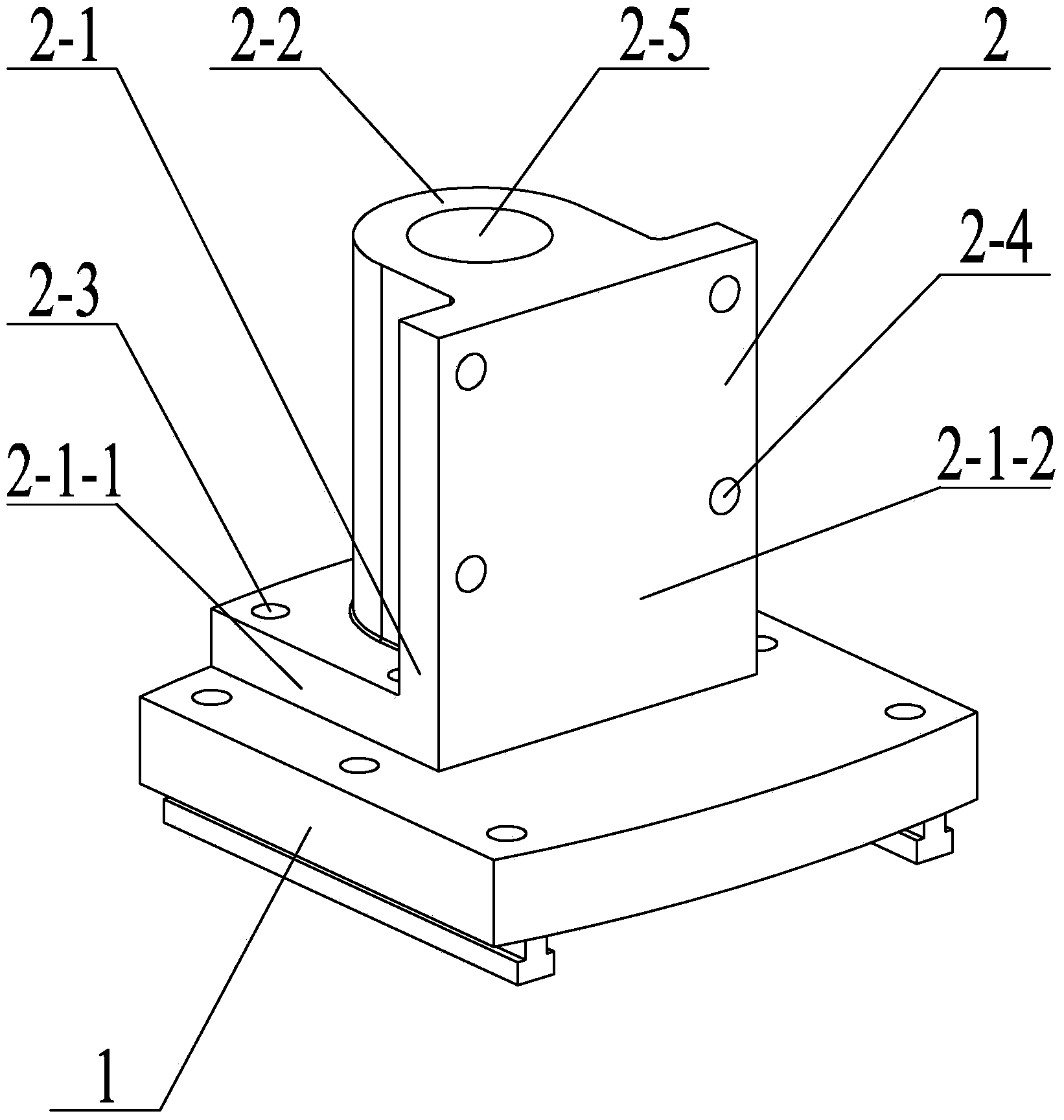

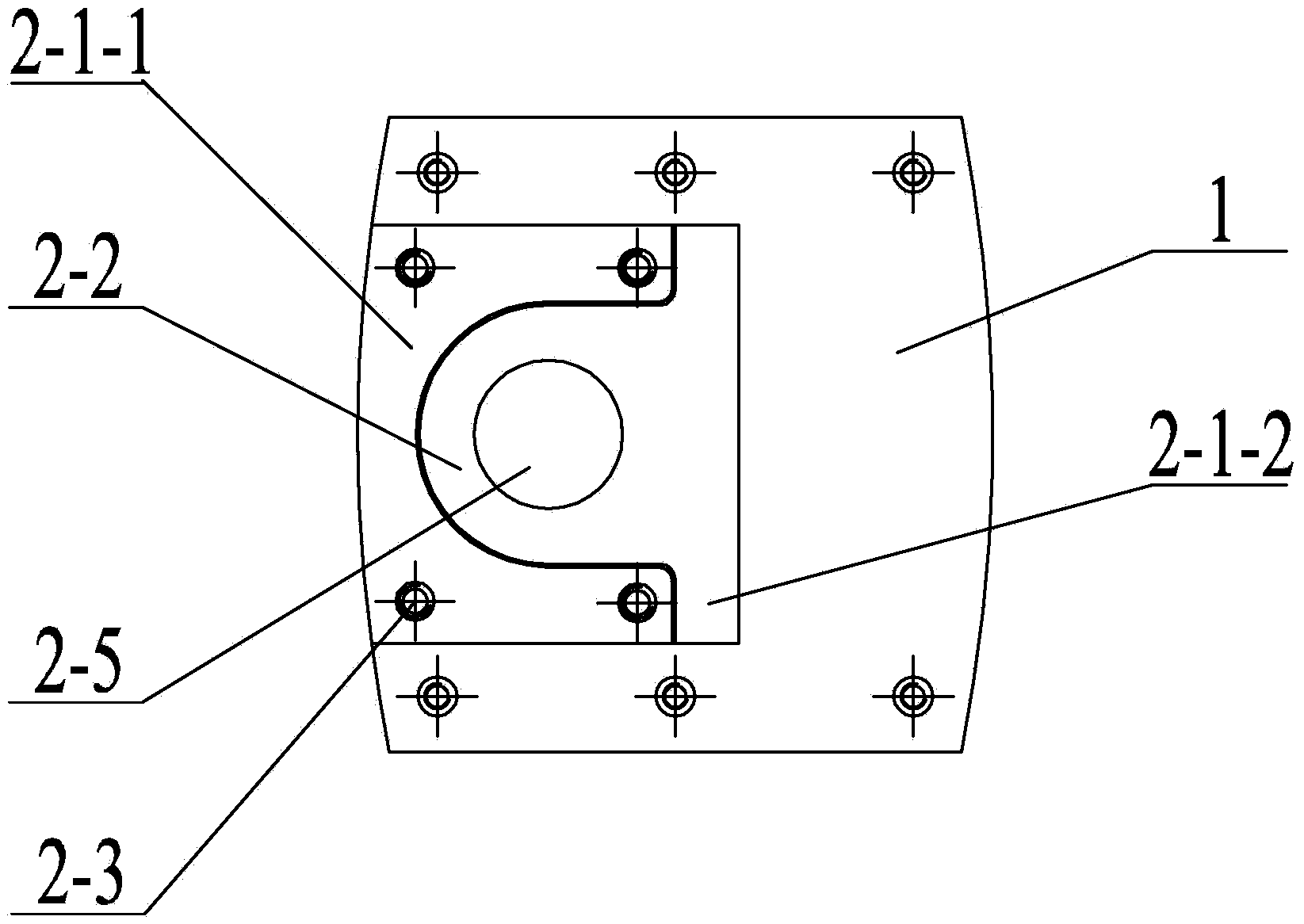

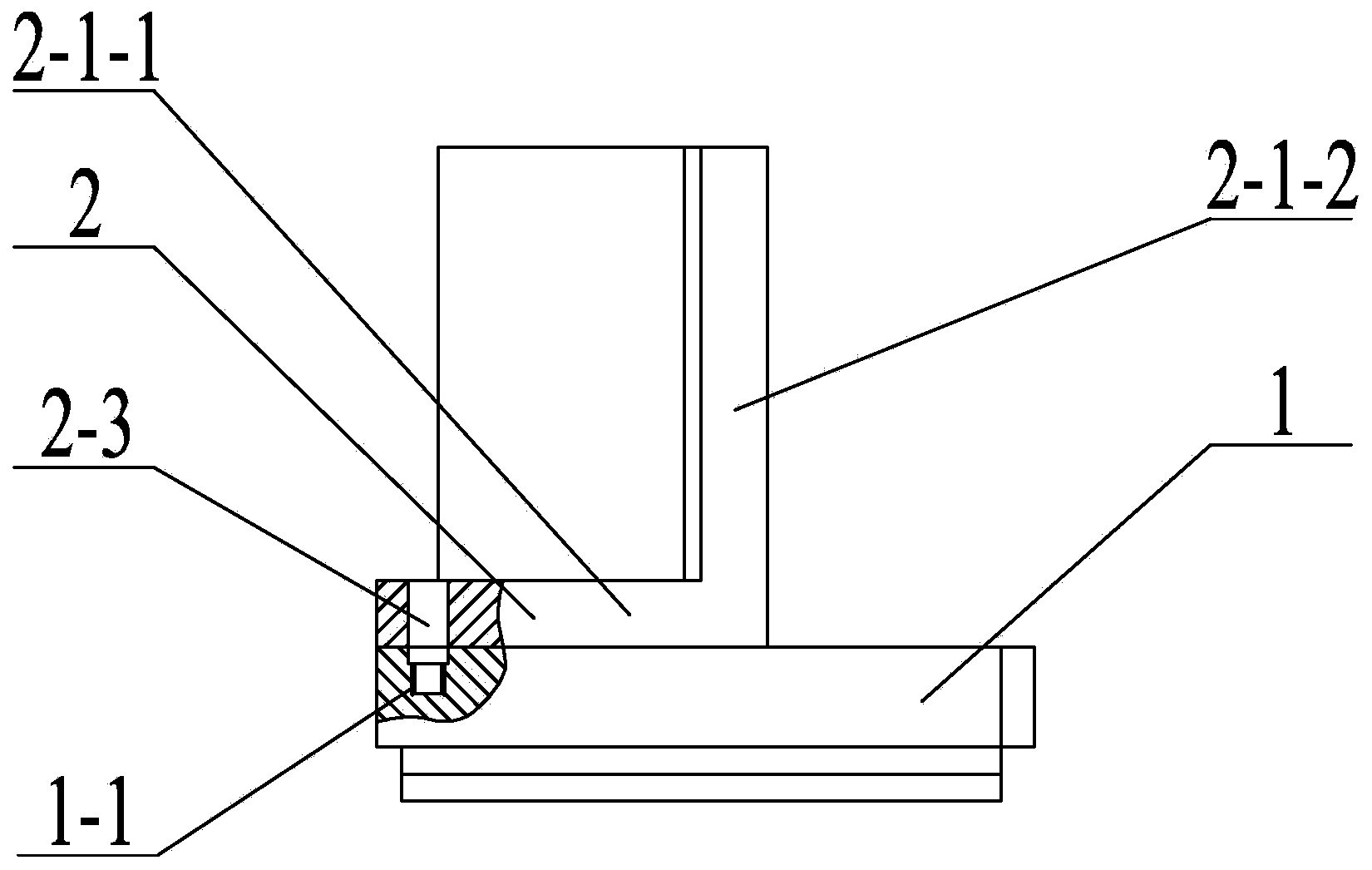

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 Explain, a kind of tool holder of the present invention is installed on the flat rotating disk and is used for two-way clamping tool rod, and the described tool rod holder that is installed on the flat rotating disk and is used for bidirectional clamping tool rod includes tool holder 1, The tool bar holder 1 is placed horizontally, and the tool bar holder installed on the flat rotating disk for bidirectional clamping tool bar also includes a bidirectional tool bar cover 2, and the bidirectional tool bar cover 2 includes an L-shaped plate 2-1 and a cylinder 2 -2, the L-shaped plate 2-1 includes a first plate 2-1-1 and a second plate 2-1-2, one end of the first plate 2-1-1 is perpendicular to one end of the second plate 2-1-2 Fixed connection, one end surface of the cylinder 2-2 is fixedly connected to the surface of the first plate 2-1-1, the side wall of the cylinder 2-2 is fixed to the surface of the secon...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 5 Note that the two rows of threaded through holes 2-6 in this embodiment are arranged at 90°, and the number of threaded through holes 2-6 in each row is two. Increase the stability of the tool holder installation. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0009] working principle

[0010] When it is necessary to change the installation method of the knife rod, the knife rod cover 1 of the present invention is removed and the installation method is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com