Support bracket, its manufacturing method, and electric power steering apparatus using the same

A manufacturing method and technology for supporting brackets, which are applied to electric steering mechanisms, power steering mechanisms, steering control mounted on vehicles, etc., can solve problems such as unrealized supporting brackets, achieve high strength and rigidity, ensure yield, The effect of manufacturing cost suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

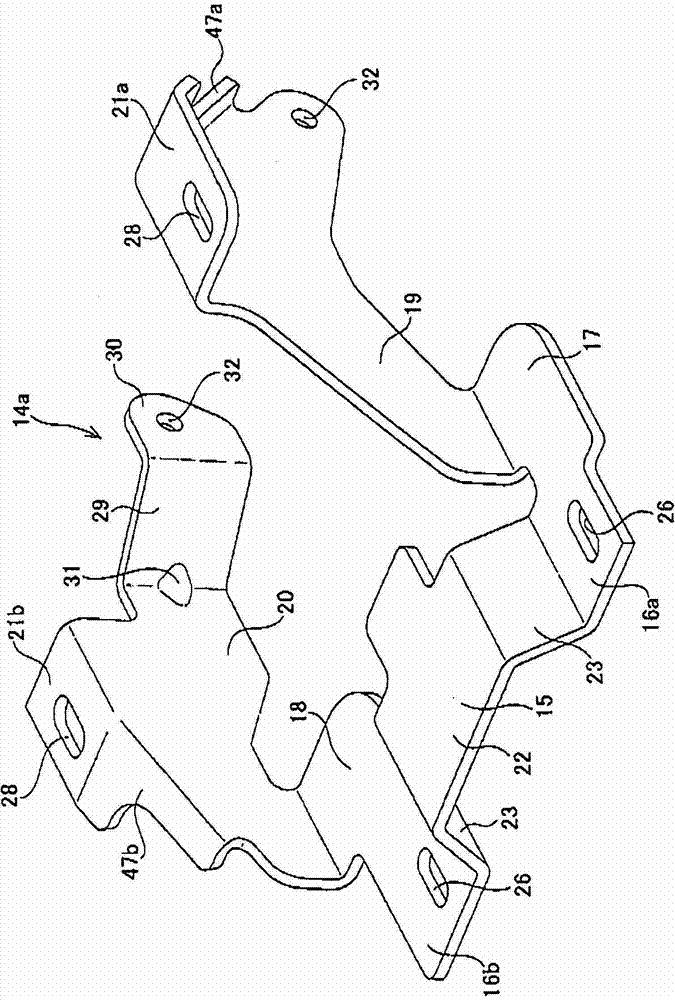

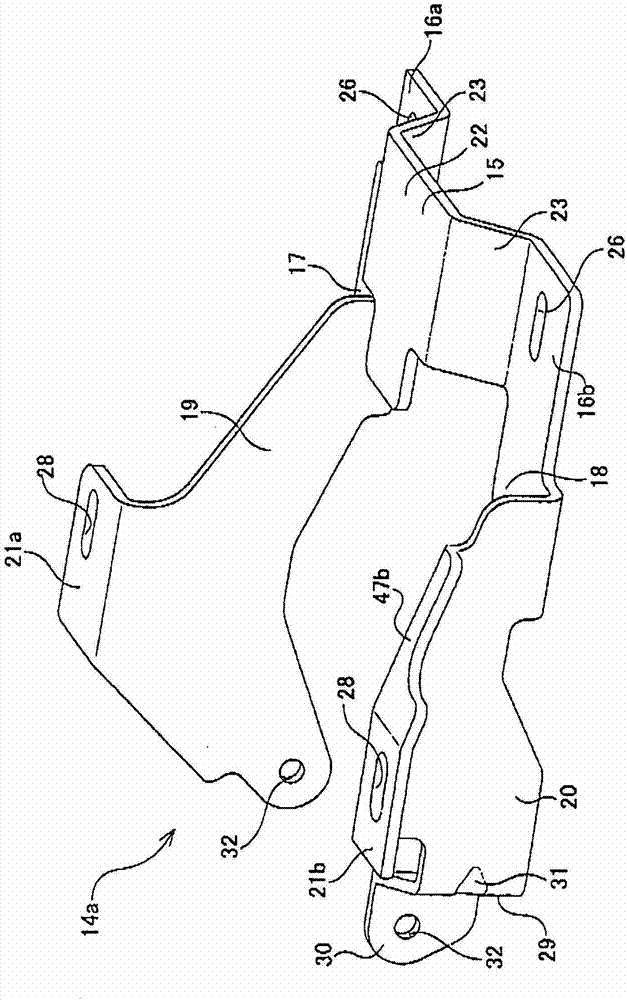

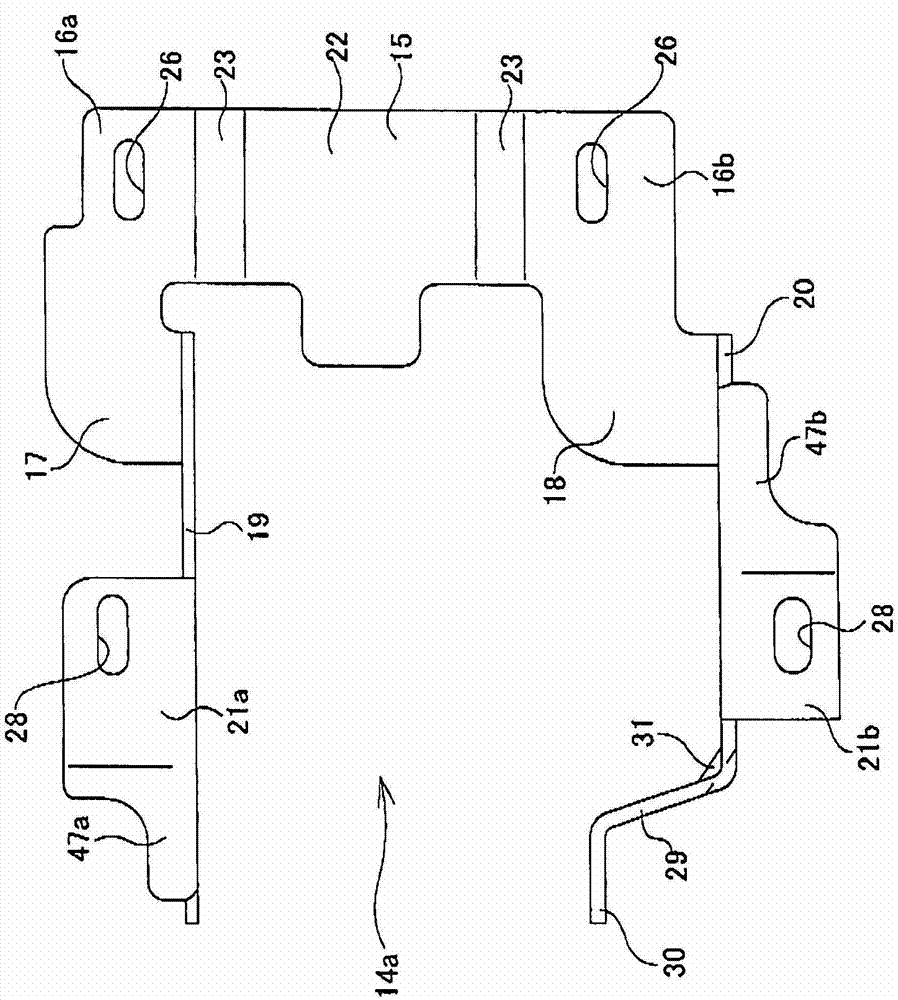

[0043] Figure 1 to Figure 13 An example of embodiment of the present invention is shown. Including this example, the present invention is characterized in that it is used to support the steering column 6a on the vehicle body 11 together with the housing 9a for supporting the components of the electric power steering device (see Figure 14 ) structure of the support bracket 14a and its manufacturing method. The basic configuration of other electric power steering devices is the same as that of conventional devices.

[0044] The support bracket 14a is integrally formed into a left-right asymmetrical shape by performing punching and bending by punching a metal plate that can ensure sufficient strength and rigidity, such as a steel plate or a stainless steel plate. The thickness of the metal plate is appropriately selected by comprehensively judging the strength, rigidity, and workability of the material used, and is, for example, about 2.0 mm to 4.0 mm when using a stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com