Hook key type roll bushing quick change device

A hook key and roll technology, which is applied in the field of hook key type roll bushing quick change device, can solve the problems of prolonging the changing time, increasing the cost, inconvenient operation, etc., achieving simple changing operation and reducing the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

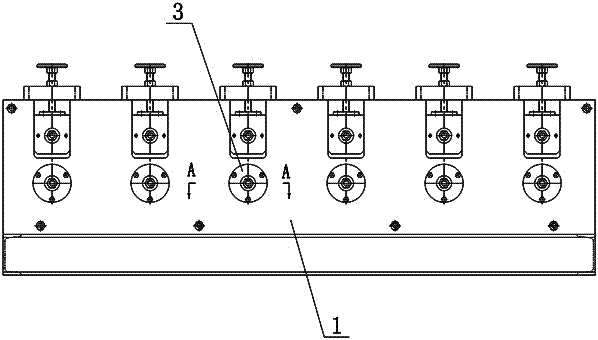

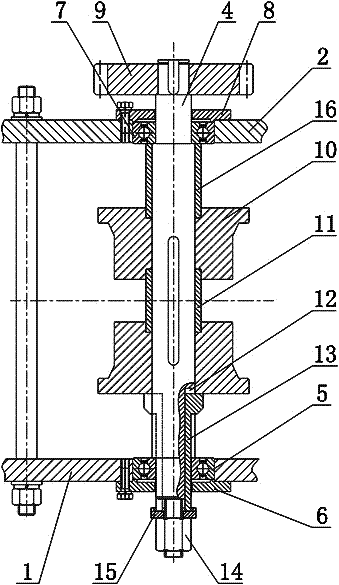

[0018] like figure 1 and figure 2 As shown, the hook key type roller bushing quick change device includes a wallboard A1, a wallboard B2, and a roll unit 3, and the roll unit 3 includes a roll shaft 4 and a roll 10. In this embodiment, the input gear 9 Installed at the end of the power transmission end of the roll shaft 4, two rolls 10 are symmetrically installed in the middle of the roll shaft 4, the shoulder at one end of the roll shaft 4 is installed on the wallboard A1 through the bearing A5, and the shoulder at the other end is passed through the bearing B7 Installed on the wall board B2, the two rolls 10 are positioned axially relative to each other through a split bush 11, the split bush 11 is two semicircular bushes, and the split bush 11 is set On the roll shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com