Retainer ring press-fitting device and retainer ring press-fitting method for rack shaft of pinion-and-rack type hydraulic steering gear

A hydraulic steering gear and rack and pinion technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to reduce investment, avoid deformation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

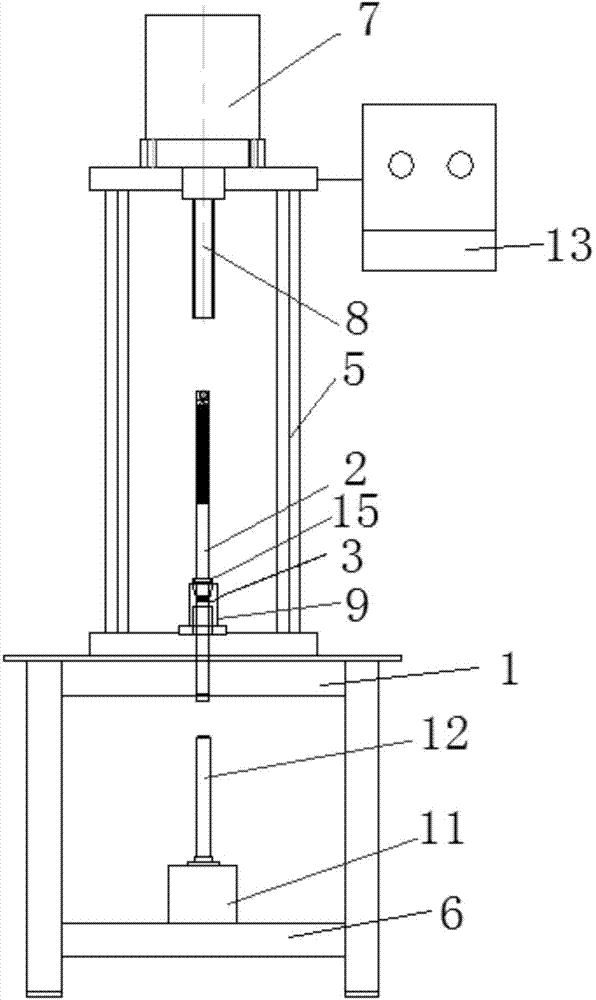

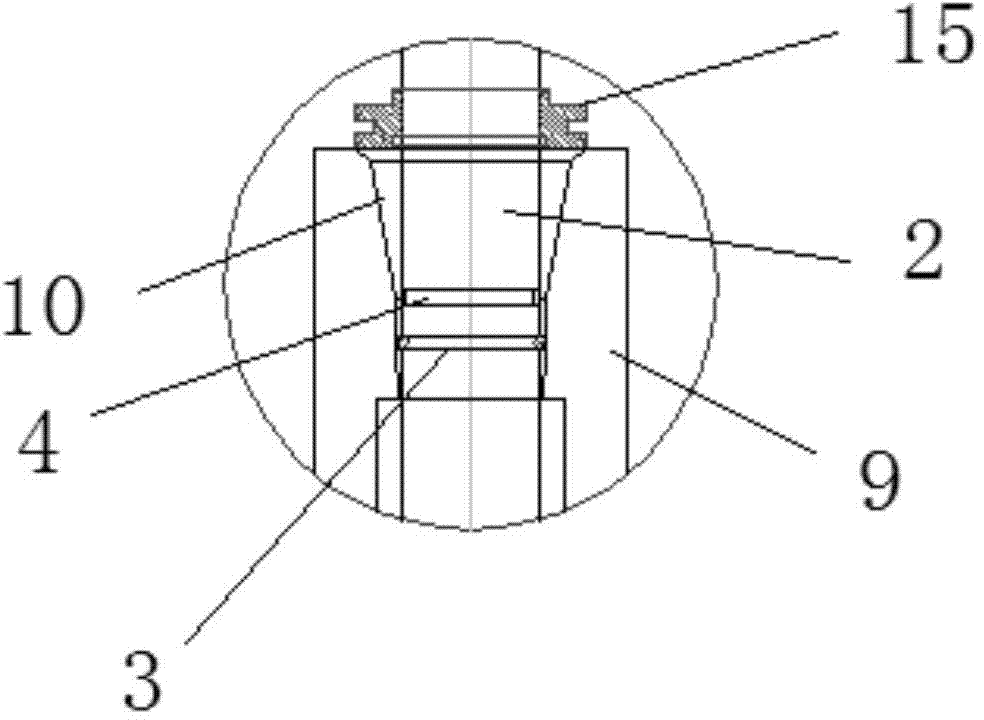

[0020] Such as Figure 1 ~ Figure 2 A rack-and-pinion type hydraulic steering gear rack shaft retaining ring pressing device is shown, including a workbench 1, a shaft retaining ring fixture set on the workbench 1, a steering gear rack 2, and a steering gear rack. The piston 15 on the bar 2, the press-fit mechanism that presses the steering gear rack 2 to the shaft retaining ring 3 in the shaft retaining ring fixture and snaps into the retaining ring groove 4 of the steering gear rack 2, presses the shaft The return mechanism that presses on the steering gear rack 2 behind the retaining ring 3. A bracket 5 is provided on the workbench 1 , and a support seat 6 is connected to the bottom of the workbench 1 . The press-fitting mechanism includes an upper cylinder 7 connected to the top of the support 5, an upper pressing head 8 connected with the piston rod of the upper cylinder 7, and the upper pressing head 8 is arranged above the retaining ring clamp for the shaft.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com