Flexible circuit board capable of being continuously discharged one by one, and preparation method thereof

A flexible circuit board and connection bit technology, applied in printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve the problems of time-consuming and laborious punching operations, loss of bulk FPC, and low single-pcs inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

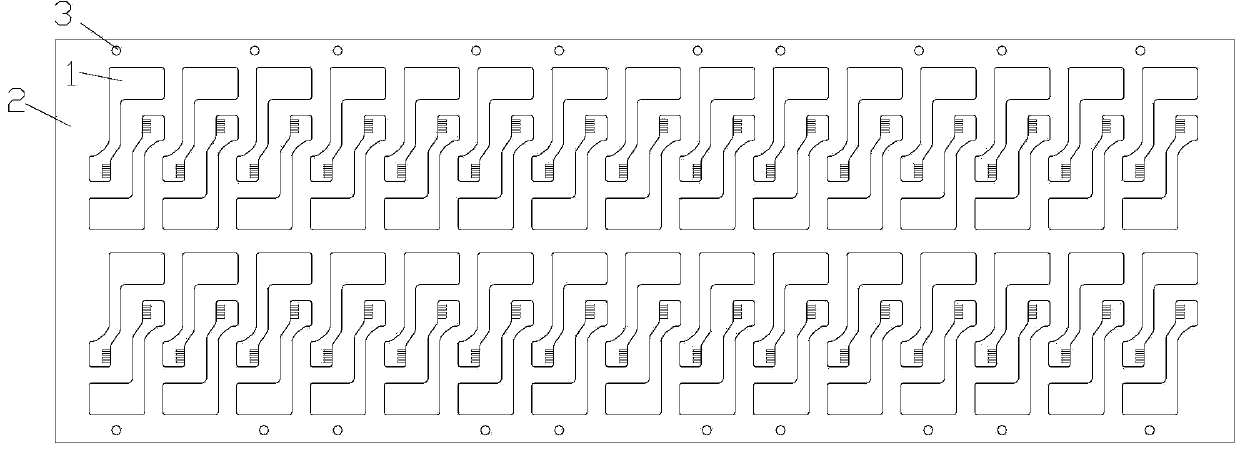

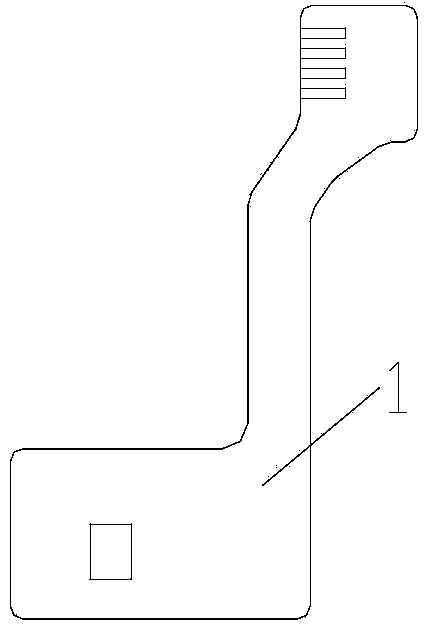

[0033] This embodiment provides a flexible circuit board shipped in pieces, including a micro-membrane 11 and several single pcs1 glued on the micro-membrane 11 and arranged neatly.

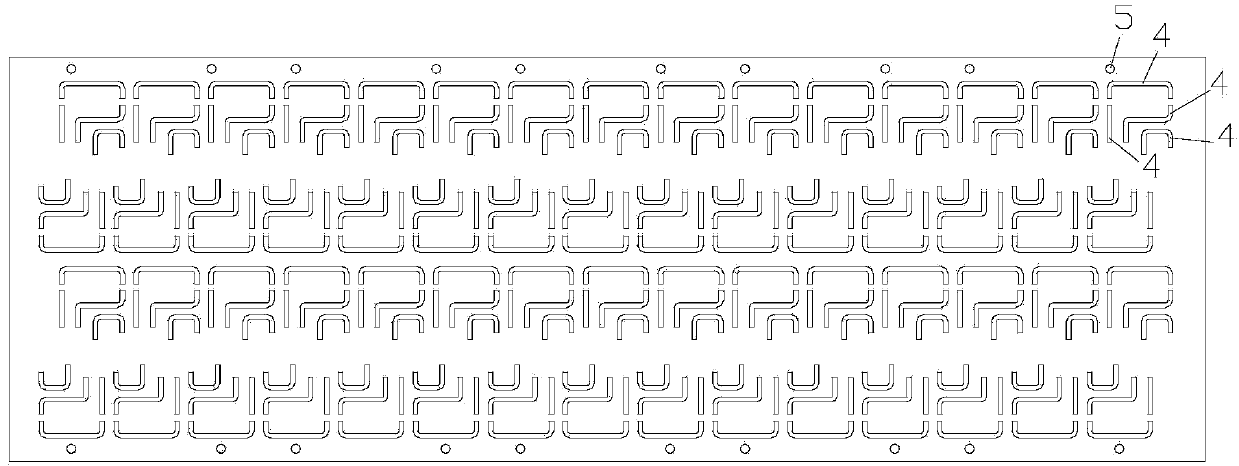

[0034] This embodiment also provides a method for preparing the flexible circuit board for continuous shipment, taking the ZTE LCD light-sensitive type button FPC board as an example, including the following steps:

[0035] Step 1: Die punching once

[0036] The flexible circuit board includes several single pcs1 and waste area 2 around several single pcs1, such as figure 1 As shown, the flexible circuit board is provided with upper and lower rows, and each row is provided with 30 single pcs1, and each single pcs1 is L-shaped, and every two single pcs1 are arranged up and down, left and right to form a group of pcs, and the flexible circuit board The upper and lower edges of the pcs are provided with positioning holes 3 with unequal spacing. Specifically, three positioning holes 3 with unequal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com