Double-robot working station for double-weld-joint arc welding

A welding robot and dual-robot technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of unstable welding joint quality, long parts processing cycle, poor welding quality stability, etc., to control welding quality and welding efficiency. , The effect of realizing long-distance operation and ensuring the quality after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

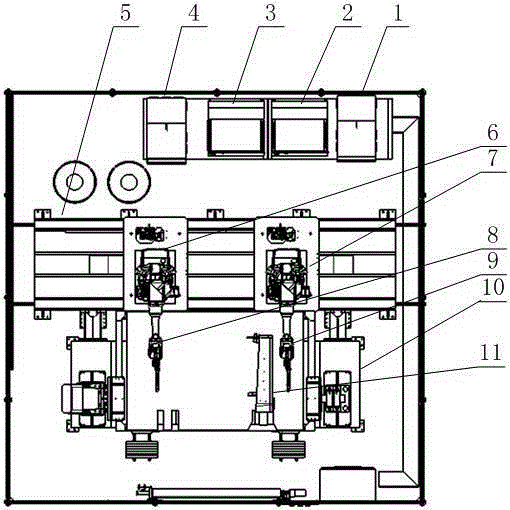

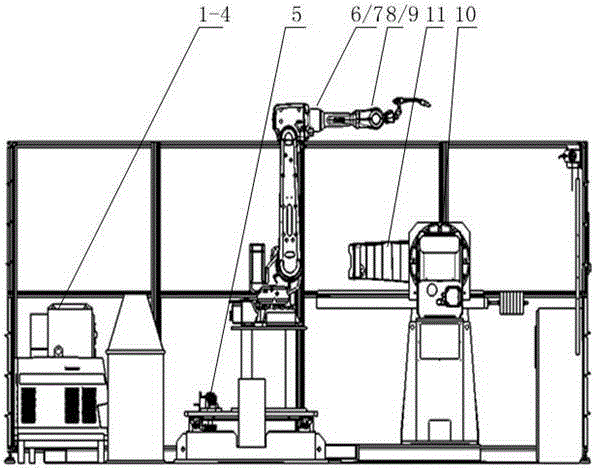

[0020] Combine below Attached picture A preferred embodiment of a dual robot workstation for double seam arc welding of the present invention will be described in detail.

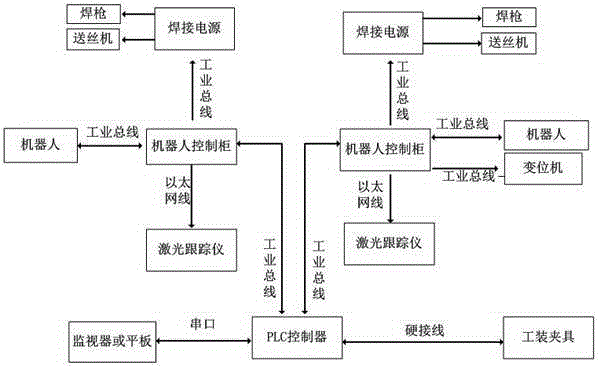

[0021] combine figure 1 , figure 2 and image 3 Show a specific embodiment of the present invention for a dual-robot workstation for double-seam arc welding: the dual-robot workstation for double-seam arc welding includes a reversing positioner 10, the reversing positioner 10 is the external axis of the welding robot 6, and the turning positioner 10 and the welding robot 6 can realize cooperative displacement; the welding fixture 11 and the turning positioner 10 are installed in one piece, and the welding fixture 11 and the turning positioner 10 move together , the laser tracker 8 and the laser tracker 9 are respectively installed on the sixth axis arm of the welding robot 6 and the welding robot 7 through the fixed bracket, the welding robot 6 and the welding robot 7 and the slide rail are posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com