Method for repairing cylinder screw holes and special scraper and screw tap for implementing method

A repair method and cylinder technology, which are applied in the directions of drilling, transportation and packaging, thread cutting tools, etc., can solve the problems of scrapped cylinders, insufficient repairing accuracy of cylinder screw holes, and difficult processing, and achieve the effect of avoiding scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

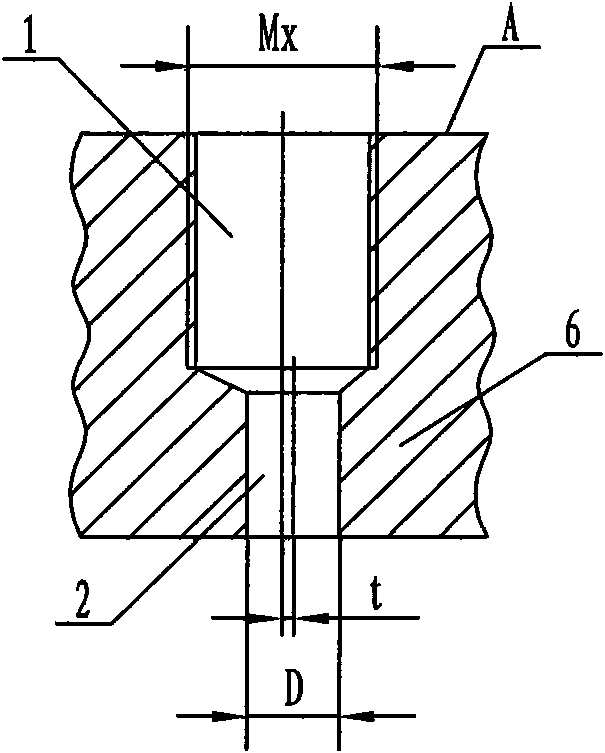

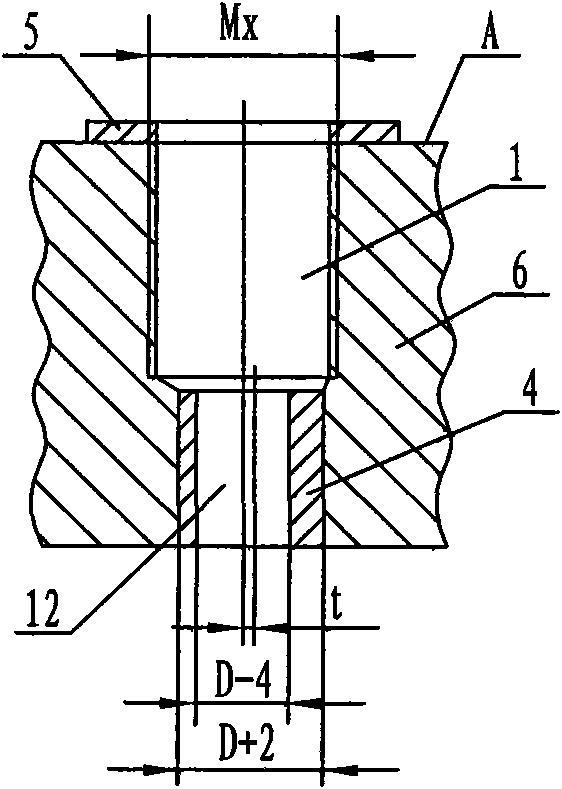

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 10 , Figure 14 and figure 1 5 illustrates this embodiment, which is realized by the following methods: Step 1, install the radial drilling machine: install the radial drilling machine on the cylinder 6 that needs to be processed, and the main shaft 3 on the radial drilling machine is connected to the The original threaded hole 1 is facing directly, and the base of the radial drilling machine is raised to the same height as the working surface of the radial drilling machine and the middle plane A of the cylinder. Within mm, the perpendicularity between the main shaft 3 on the radial drilling machine and the facet A in the cylinder is within 0-0.03mm, use the inclined iron and the dial indicator to align the radial drilling machine and then fix the radial drilling machine with bolts; Step 2 , Reaming: install the drill bit in the spindle hole of the radial drilling machine, the diam...

specific Embodiment approach 2

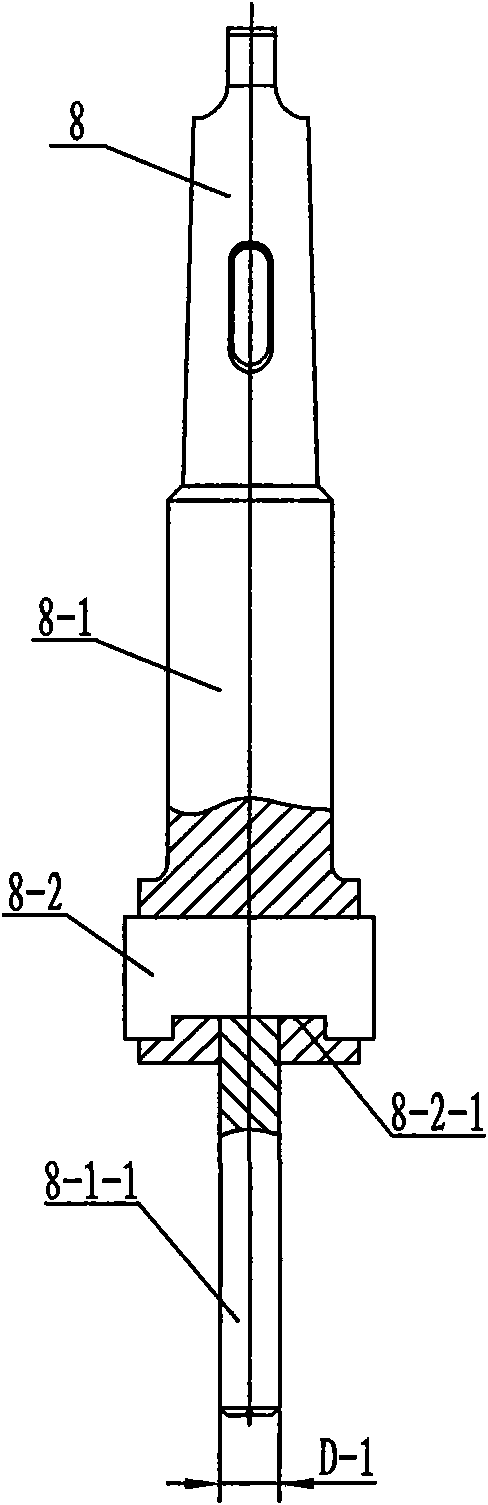

[0008] Specific implementation mode two: combination Figure 3 to Figure 9 Describe this embodiment, the scraper 8 of this embodiment is made up of scraper rod 8-1 and scraper blade 8-2, and the lower end of scraper rod 8-1 is provided with positioning bar 8-1-1, and the position of positioning bar 8-1-1 The diameter is D-1, and the upper end of the positioning bar 8-1-1 is provided with a shoulder 8-1-2 on the scraper bar 8-1, the length of the shoulder 8-1-2 is L, the width is h, and the shoulder 8-1-2 has a blade installation hole 8-1-3 along the width direction, and the upper end of the scraper blade 8-2 is provided with a groove 8-2-1 that matches the shoulder 8-1-2, and the scraper blade 8- The blade outer diameter D1 of 2 is Mx+1. A positioning rod 8-1-1 is designed on the scraper 8, so that the processed holes can meet the precision requirements. The sum of the height B of the shoulder 8-1-2 and the length C of the positioning rod 8-1-1 should be greater than the sum...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 10 ~ Figure 13 Describe this embodiment, the screw tap 9 of this embodiment is made up of taper shank 9-1, top 9-2, wrench 9-3, connecting rod 9-4, two positioning keys 9-5 and tap sleeve 9-6, and the top The upper end of 9-2 is installed in the center hole of the lower end of the taper handle 9-1, the apex head of the lower end of the top 9-2 is on the center of the upper end face of the wrench 9-3, and the upper end of the extension rod 9-4 is installed on the top of the wrench 9-3. In the central hole, the lower end of the connecting rod 9-4 is provided with a connecting rod 9-4-1, and the connecting rod 9-4 is symmetrically provided with two first positioning keyways 9-4-2 above the connecting rod 9-4-1. The center of the tap sleeve 9-6 is provided with a connecting rod mounting hole 9-6-1, and the upper end face of the tap sleeve 9-6 is symmetrically provided with two second positioning keyways 9 equal in widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com