One-step-process hydrophilic dacron/high-shrinkage dacron combined yarn and preparation method thereof

A high-shrinkage, hydrophilic technology, applied in the direction of melt spinning, artificial filament heat treatment, conjugated synthetic polymer rayon, etc., to achieve the effect of fluffy appearance, bright color and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

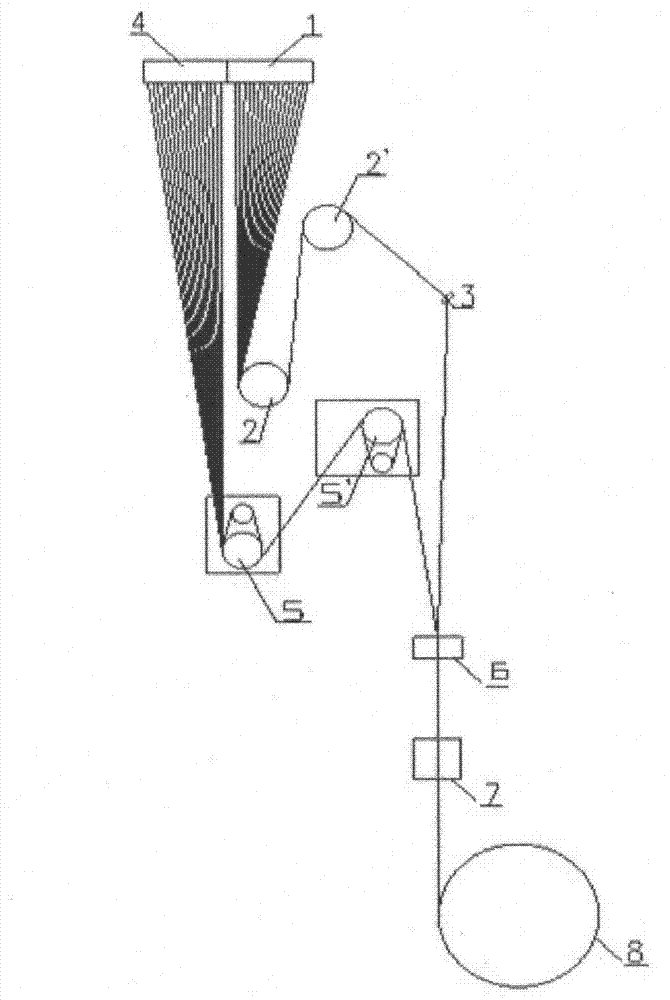

Method used

Image

Examples

Embodiment 1

[0027] Raw materials: The content of each component in the hydrophilic copolyester chip is as follows:

[0028] PTA:EG:SIPE:X1:X2 molar ratio is 1:1.1:0.015:0.005:0.000166

[0029] The content of each component in the high shrinkage copolyester chip is as follows:

[0030] PTA:EG:IPA molar ratio is 1:1.1:0.01

[0031] The melting point of hydrophilic copolyester chips is 228.1°C, and the intrinsic viscosity [η] is 0.751dL / g.

[0032] The high-shrinkage copolyester chip has a melting point of 221.4°C and an intrinsic viscosity [η] of 0.85dL / g.

[0033]Preparation method of hydrophilic copolyester chips: using continuous polymerization equipment, continuously and accurately weigh PTA, EG, and X1 with a molar ratio of 0.5% to PTA, respectively, and add them to the beating kettle for beating. The molar ratio is 1:1.1; the above slurry is continuously and uniformly transported to the first esterification tank, the reaction temperature of the first esterification tank is 240°C, a...

Embodiment 2

[0037] Raw materials: The content of each component in the hydrophilic copolyester chip is as follows:

[0038] PTA:EG:SIPE:X1:X2 molar ratio is 1:1.1:0.03:0.02:0.006

[0039] The content of each component in the high shrinkage copolyester chip is as follows:

[0040] PTA:EG:IPA molar ratio is 1:1.1:0.15

[0041] The melting point of hydrophilic copolyester chips is 240.1°C, and the intrinsic viscosity [η] is 0.606dL / g.

[0042] The high-shrinkage copolyester chip has a melting point of 218.4°C and an intrinsic viscosity [η] of 0.622dL / g.

[0043] Preparation method of hydrophilic copolyester chips: using continuous polymerization equipment, continuously and accurately weigh PTA, EG, and X1 with a molar ratio of 2% to PTA, respectively, and add them to the beating kettle for beating. The molar ratio is 1:1.1; the above slurry is continuously and uniformly transported to the first esterification tank, the reaction temperature of the first esterification tank is 240°C, and th...

Embodiment 3

[0047] Raw materials: The content of each component in the hydrophilic copolyester chip is as follows:

[0048] PTA:EG:SIPE:X1:X2 molar ratio is 1:1.1:0.06:0.08:0.01245

[0049] The content of each component in the high shrinkage copolyester chip is as follows:

[0050] PTA:EG:IPA molar ratio is 1:2.5:0.2

[0051] The melting point of hydrophilic copolyester chips is 242.2°C, and the intrinsic viscosity [η] is 0.615dL / g.

[0052] The high-shrinkage copolyester chip has a melting point of 210.4°C and an intrinsic viscosity [η] of 0.502dL / g.

[0053] Preparation method of hydrophilic copolyester chips: using continuous polymerization equipment, continuously and accurately weigh PTA, EG, and X1 with a molar ratio of 8% to PTA, respectively, and add them to the beating kettle for beating. The molar ratio is 1:1.1; the above slurry is continuously and uniformly transported to the first esterification tank, the reaction temperature of the first esterification tank is 240°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com