Laminated glass capable of emitting light

A technology of laminated glass and inner glass, applied in windshield, glass/slag layered products, layered products, etc., can solve the problems of no sense of layering, no obvious directionality of output light, etc., and achieve a simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

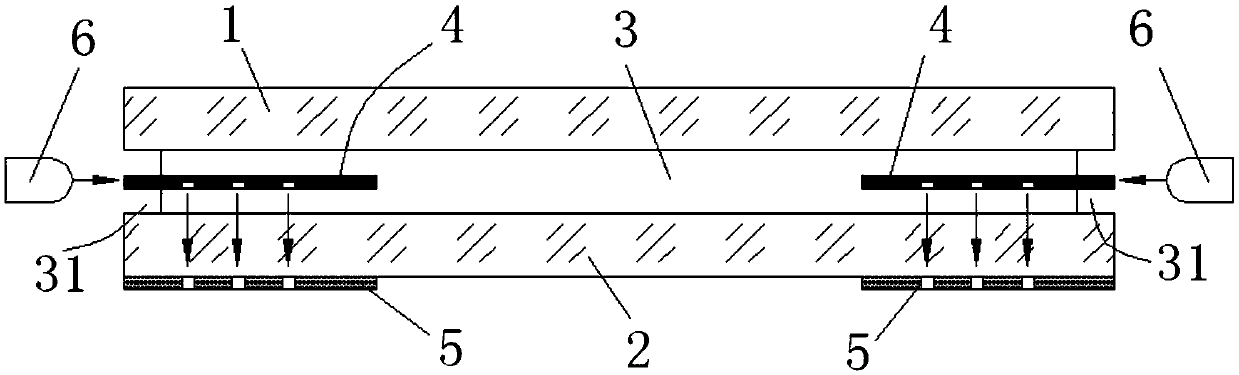

[0049] 1) The thickness is 2.1mm, and the length and width are 300×300mm 2 The gray transparent glass plate is used as the inner glass 2, with a thickness of 2.1mm and a length and width of 300×300mm 2 The white transparent glass plate is used as the outer glass 1.

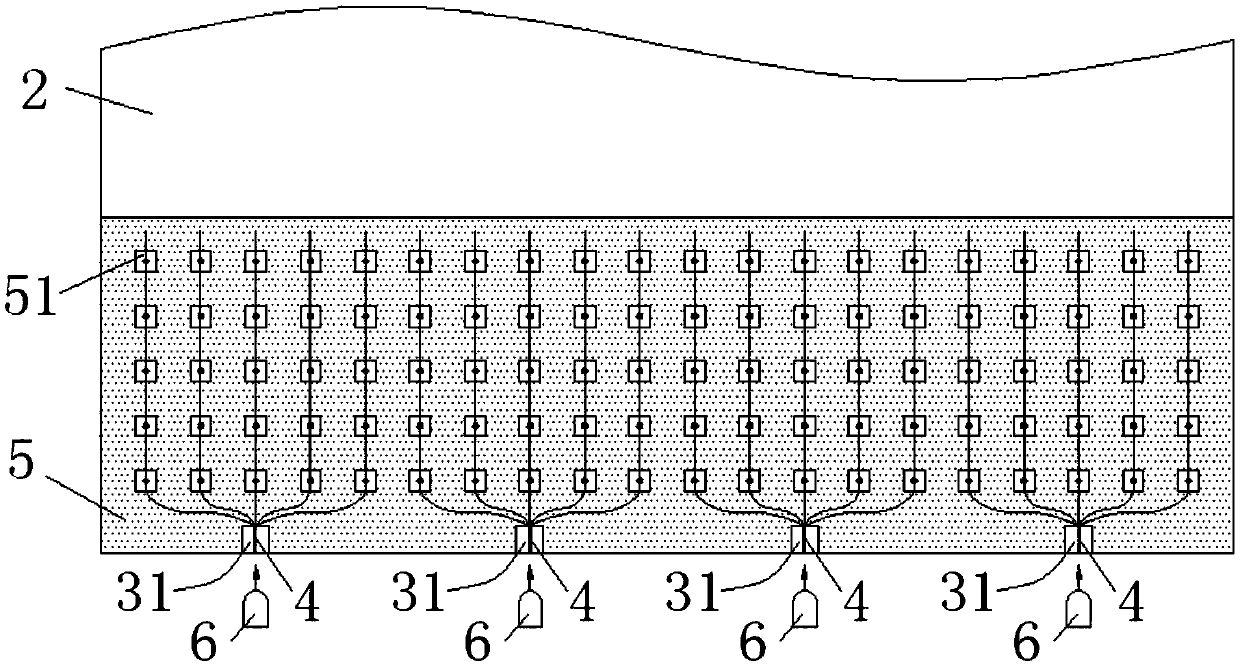

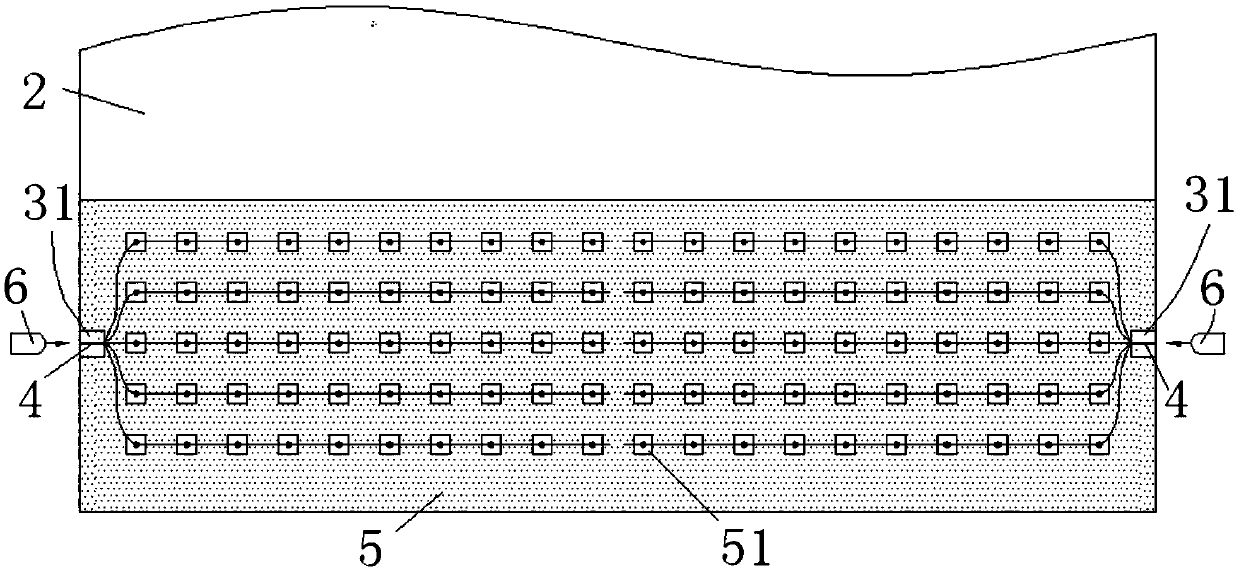

[0050] 2) Take a piece with a thickness of 0.38mm and a length and width of 300×300mm 2 The transparent PVB film (refractive index 1.49), with the aid of tools such as templates, the optical fiber bundle 4 that is split and provided with a cutting part is laid on the transparent PVB film (refractive index 1.49) according to a certain pattern, and the optical fiber bundle is kept The head end of 4 is aligned with the edge of PVB film.

[0051] 3) Another transparent PVB film (refractive index: 1.49) of the same size is covered on the optical fiber bundle 4, and the two PVB films above and below the optical fiber bundle 4 are completely overlapped. Each optical fiber bundle 4 includes 25 optical fiber cores, the ...

Embodiment 2

[0056] 1) The thickness is 2.1mm, and the length and width are 300×300mm 2 The green transparent glass plate is used as the inner glass 2, with a thickness of 2.1mm and a length and width of 300×300mm 2 The white transparent glass plate is used as the outer glass 1.

[0057] 2) Take a piece with a thickness of 0.38mm and a length and width of 300×300mm 2The transparent PVB film (refractive index 1.49), with the aid of tools such as templates, the optical fiber bundles 4 that are split and provided with corroded parts are arranged on the transparent PVB film (refractive index 1.49) according to a certain pattern, and the optical fiber bundles are kept The head end of 4 is aligned with the edge of PVB film.

[0058] 3) Another transparent PVB film (refractive index: 1.49) of the same size is covered on the optical fiber bundle 4, and the two PVB films above and below the optical fiber bundle 4 are completely overlapped. Each optical fiber bundle 4 includes 15 optical fiber co...

Embodiment 3

[0063] 1) The thickness is 2.1mm, and the length and width are 300×300mm 2 The green transparent glass plate is used as the inner glass 2, with a thickness of 2.1mm and a length and width of 300×300mm 2 The white transparent glass plate is used as the outer glass 1.

[0064] 2) Take a piece with a thickness of 0.38mm and a length and width of 300×300mm 2 transparent PVB film (refractive index 1.49), with the aid of tools such as templates, the split optical fiber bundle 4 is arranged on the transparent PVB film (refractive index 1.49) according to a certain pattern, and the head end of the optical fiber bundle 4 is kept in contact with the PVB film edges are aligned.

[0065] 3) Another transparent PVB film (refractive index: 1.49) of the same size is covered on the optical fiber bundle 4, and the two PVB films above and below the optical fiber bundle 4 are completely overlapped. Each optical fiber bundle 4 includes 20 optical fiber cores, the diameter of the optical fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com