Method and equipment preparing viscose filament non-woven fabric through wet spinning technology

A filament non-woven fabric and viscose fiber technology, which is applied in spinning solution preparation, wet spinning method, fiber processing and other directions, can solve the problem that the properties of viscose fiber cannot be effectively reflected, is not suitable for popularization and application, and has a narrow application field. and other problems, to achieve the effect of improving washing effect, better effect and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

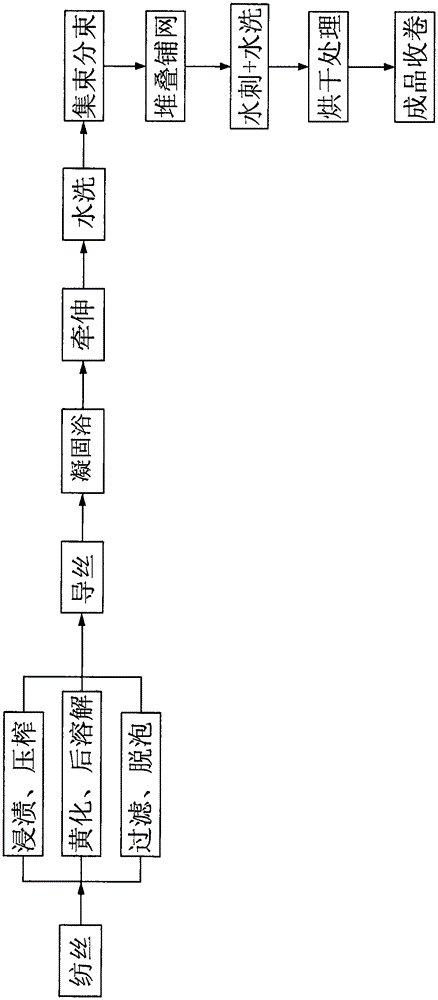

[0051] (1), preparation of spinning dope: the preparation process is composed of dipping, pressing, yellowing, post-dissolving, filtering, and degassing processes to obtain spinning dope for producing viscose fiber;

[0052] (2) Coagulation reaction of stock solution: wet forming is adopted, the stock solution is extruded from the spinneret hole to form a thin stream, and the spinning stock solution is directly contacted with the coagulant in the coagulation bath for spinning;

[0053] (3) Viscose fiber forming: the thin stream of stock solution is solidified into primary fibers, which are exported by godet rollers;

[0054] (4), drafting: Stretch the primary fiber to improve the mechanical properties of the fiber;

[0055] (5) Neutralization and washing: neutralize and wash the as-spun fiber to neutralize the acid and alkali in the fiber to achieve neutrality;

[0056] Non-woven fabric forming process

[0057] (6) Laying: The washed viscose filaments are evenly dispersed an...

Embodiment 1

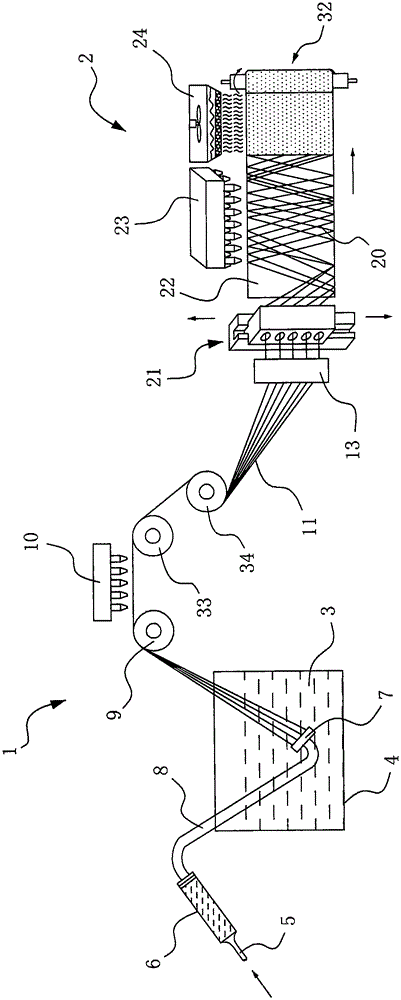

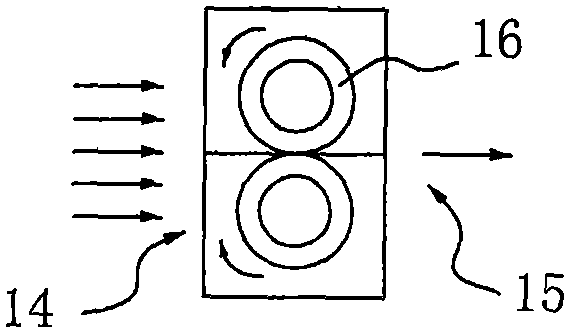

[0063] Such as figure 2 , 3, 4, 5, and 6, a device for preparing viscose filament nonwoven fabrics based on wet spinning technology is composed of wet spinning device 1 and nonwoven fabric forming device 2, and the wet spinning The silk device 1 consists of a coagulation bath container 4 with a coagulation bath 3, a filter 6 with a spinning stock solution inlet 5, the spinning stock solution enters the filter 6 through the spinning stock solution inlet 5, connects the filter 6 and extends into the coagulation The liquid inlet pipe 8 with the spinneret 7 in the bath container 4, the godet roll 9 and the washing device 10 for connecting the spinning place of the spinneret 7, and the washing device 10 can adopt ultrasonic cleaning or pure water commonly used in the art. Spray cleaning, the forming device 2 includes a clustering and splitting device 13 for concentrating and dispersing the viscose fiber tow 11, the clustering and splitting device 13 includes a pair of mutually en...

Embodiment 2

[0066] In order to meet the actual production needs, a winding mechanism 32 can be set at the output end of the web forming machine web curtain 22, and the filament fiber web 20 on the web forming machine web curtain 22 is dried by the drying mechanism 24 and then rolled. Mechanism 32 is directly wound and packaged. Between the godet roll 9 and the bunching and splitting device 13, a drafting roll for improving the strength of the viscose fiber tow 11 can also be selected, and the drafting roll is composed of a main drafting roll 33 and a secondary drafting roll 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com