Equipment and process for preparing low-melting-point chinlon hot melt yarn

A technology of thermal fuse and low melting point, which is applied in the production of complete sets of equipment for artificial threads, melt spinning, filament forming treatment, etc. It can solve the problem of low strength of low melting point nylon thermal fuse, and achieve increased strength and convenient use , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

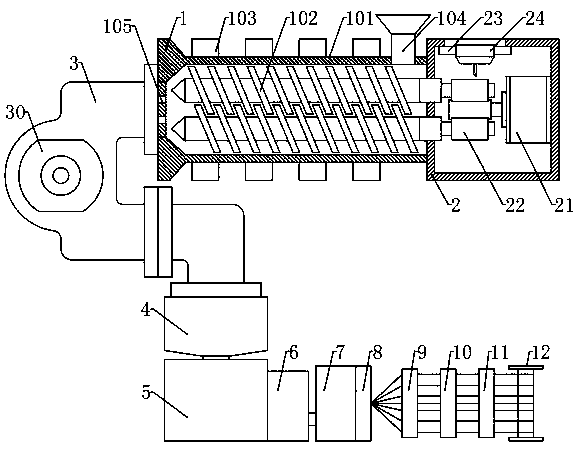

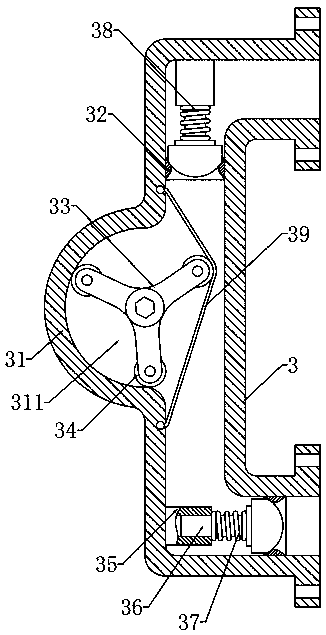

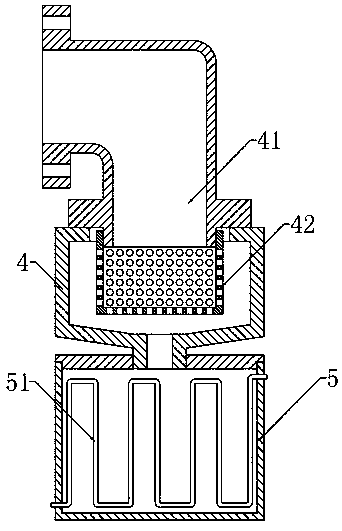

[0034] Such as figure 1 , 2 , 3, 4, and 5 show a kind of low-melting-point nylon hot-melt yarn preparation equipment, including heating extruder 1, power box 2, pressurizing device 3, filter box 4, insulation box 5, metering pump 6, spinning Assembly 7, spinneret 8, guide roll 9, first heat roll 10, second heat roll 11 and winding device 12, described heating extruder 1 comprises extruder housing 101, two screw rods 102 and Several electric heating rings 103.

[0035] Such as figure 1 As shown, the longitudinal end of the extruder housing 101 is provided with a feed funnel 104, the extruder housing 101 is provided with a discharge port at the other longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com