Preparation method of graphene antibacterial melt-blown cloth and application thereof

A technology of graphene and melt-blown cloth, which is applied in application, melt spinning, non-woven fabrics, etc., can solve the problems of reduced filtration function, prolonged use of masks, and reduced filtration efficiency, and achieves improved lipophilicity and good bactericidal effect , the effect of reducing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

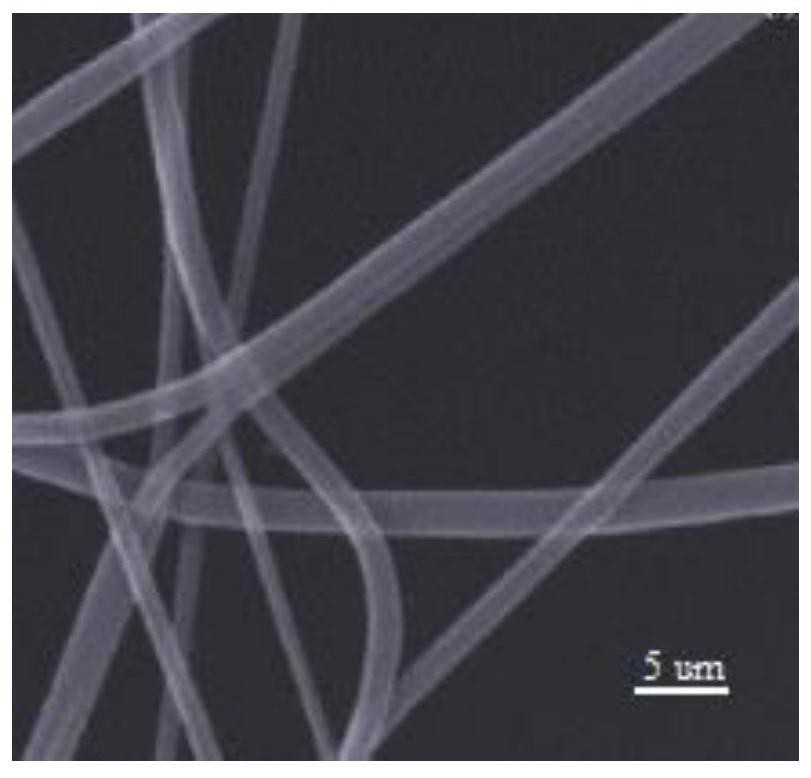

Image

Examples

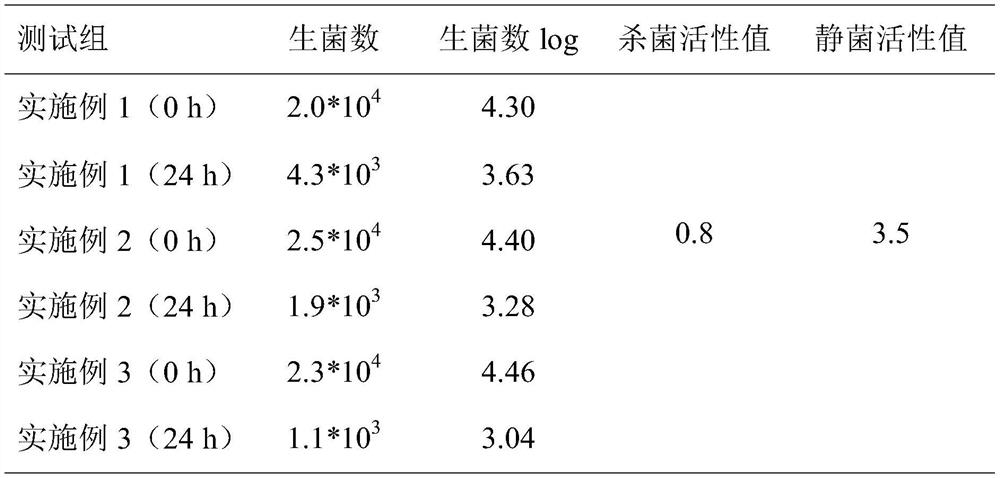

Embodiment 1

[0027] A preparation method of graphene antibacterial melt blown cloth, the preparation method of described graphene antibacterial spray cloth comprises the following preparation steps:

[0028] Step 1, preparation of modified polypropylene resin: first place the silica in a vacuum drying oven and dry it under vacuum at 125°C for 10 hours, weigh 10g of nano-silica and add it to a 500mL three-neck flask, then add 250mL of toluene, and use a magnetic force to Stir it evenly with a stirrer; then weigh 5% of the KH560 coupling agent by mass of silica and add it to a clean and dry three-necked flask, use an ultrasonic mixer to oscillate and disperse for 15 minutes, and place the mixed solution in a water bath reflux reaction device , reacted at 100°C for 2.0 h, washed with absolute ethanol and filtered, and dried for use; finally, fully dried modified and unmodified nano-silica were mixed in a molar ratio of 1:1 , to obtain mixed nano-silica, and then mix the mixed nano-silica and ...

Embodiment 2

[0042] A preparation method of graphene antibacterial melt blown cloth, the preparation method of described graphene antibacterial spray cloth comprises the following preparation steps:

[0043] Step 1, preparation of modified polypropylene resin: first place the silica in a vacuum drying oven and dry it in vacuum at 130°C for 9 hours, weigh 10g of nano-silica and add it to a 500mL three-neck flask, then add 280mL of toluene, use magnetic Stir it evenly with a stirrer; then weigh 5.5% KH560 coupling agent by mass of silica and add it into a clean and dry three-necked flask, use an ultrasonic mixer to vibrate and disperse for 18 minutes, and place the mixed solution in a water bath reflux reaction device , reacted at 100°C for 2.0 h, washed with absolute ethanol and filtered, and dried for use; finally, fully dried modified and unmodified nano-silica were mixed in a molar ratio of 1:1 , to obtain mixed nano-silica, and then mix the mixed nano-silica and polypropylene slices eve...

Embodiment 3

[0057] A preparation method of graphene antibacterial melt blown cloth, the preparation method of described graphene antibacterial spray cloth comprises the following preparation steps:

[0058] Step 1, preparation of modified polypropylene resin: first place the silica in a vacuum drying oven and dry it under vacuum at 135°C for 8 hours, weigh 10g of nano-silica and add it to a 500mL three-neck flask, then add 300mL of toluene, and use a magnetic Stir it evenly with a stirrer; then weigh 6% KH560 coupling agent of silica mass and add it into a clean and dry three-necked flask, use an ultrasonic mixer to oscillate and disperse for 20 minutes, and place the mixed solution in a water bath reflux reaction device , reacted at 100°C for 2.5 hours, washed with absolute ethanol and filtered, and dried for use; finally, fully dried modified and unmodified nano-silica were mixed in a molar ratio of 1:1 , to obtain mixed nano-silica, and then mix the mixed nano-silica and polypropylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com