Polylactic acid double-component composite fiber double-spray-orifice parallel type spinning component

A composite fiber and spinning assembly technology, which is applied in the field of polylactic acid bicomponent composite fiber double jet orifice parallel spinning assembly, can solve the problem of inaccurate mutual positioning of parts, large melt stress fluctuation, and influence on spinning. Operation efficiency and other issues, to achieve the effect of not easy to break, high spinning efficiency, and convenient spinning production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

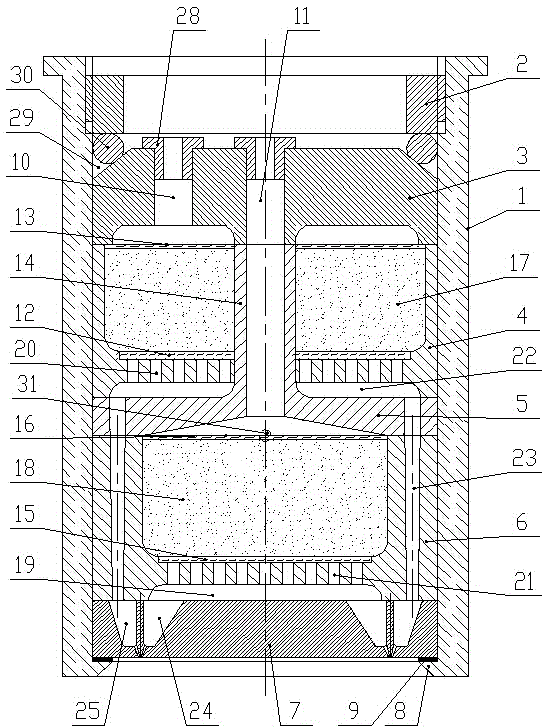

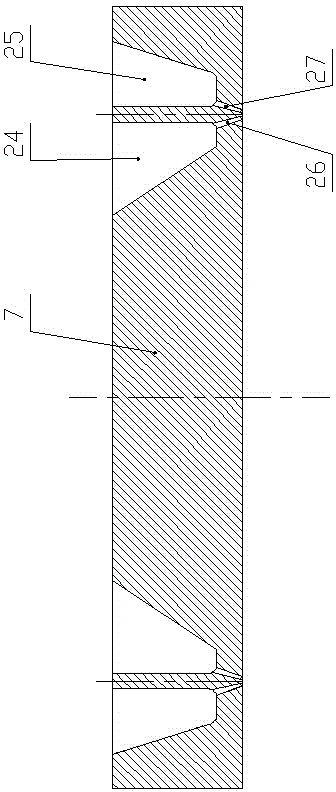

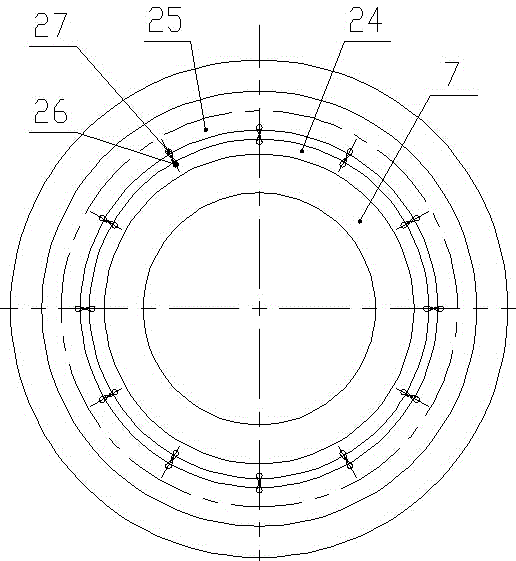

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the polylactic acid two-component composite fiber double-nozzle side-by-side spinning assembly of the present invention includes a cylindrical body 1 with an open top and bottom, and a compression nut is arranged inside the cylindrical body 1 from top to bottom. 2. The melt distribution plate 3, the upper sand cup 4, the feed distribution plate 5, the lower sand cup 6 and the spinneret 7, the inner wall of the lower end of the cylinder body 1 is provided with a limit ring 8, the limit ring 8 and the lower end of the spinneret 7 A sealing washer 9 is arranged between them, and the compression nut 2 is threadedly connected with the upper part of the inner wall of the cylindrical body 1 .

[0031] The melt distribution plate 3 is respectively provided with a feed port 10 for component A of polylactic acid and a feed port 11 for component B of polylactic acid. The inner bottom is provided with a first upper fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com