Spinning machine and method for producing biomass polyamide 56 fibers

A spinning machine and polyamide technology, which is applied in the field of spinning machines for producing biomass polyamide 56 fibers, and can solve problems such as unstable product quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

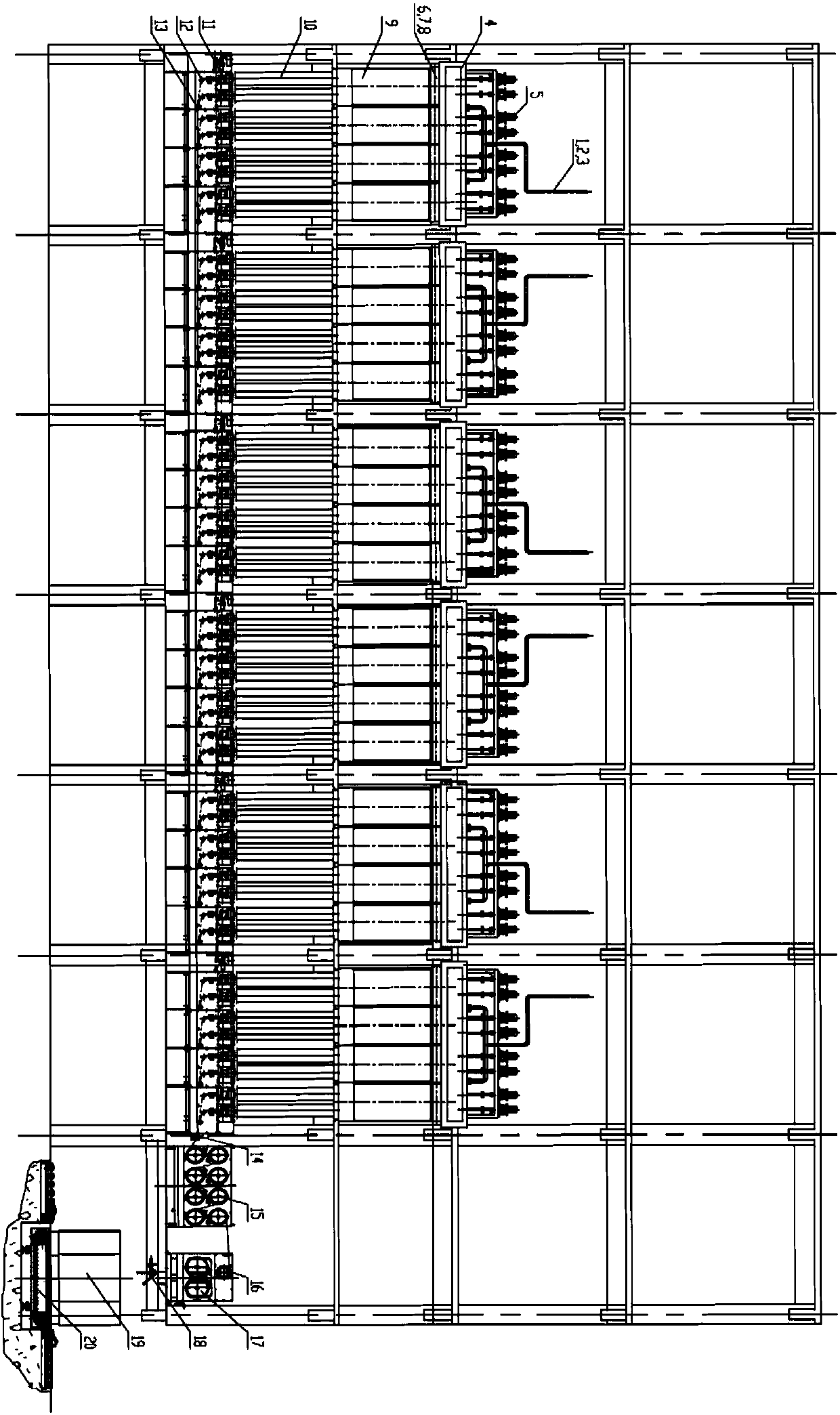

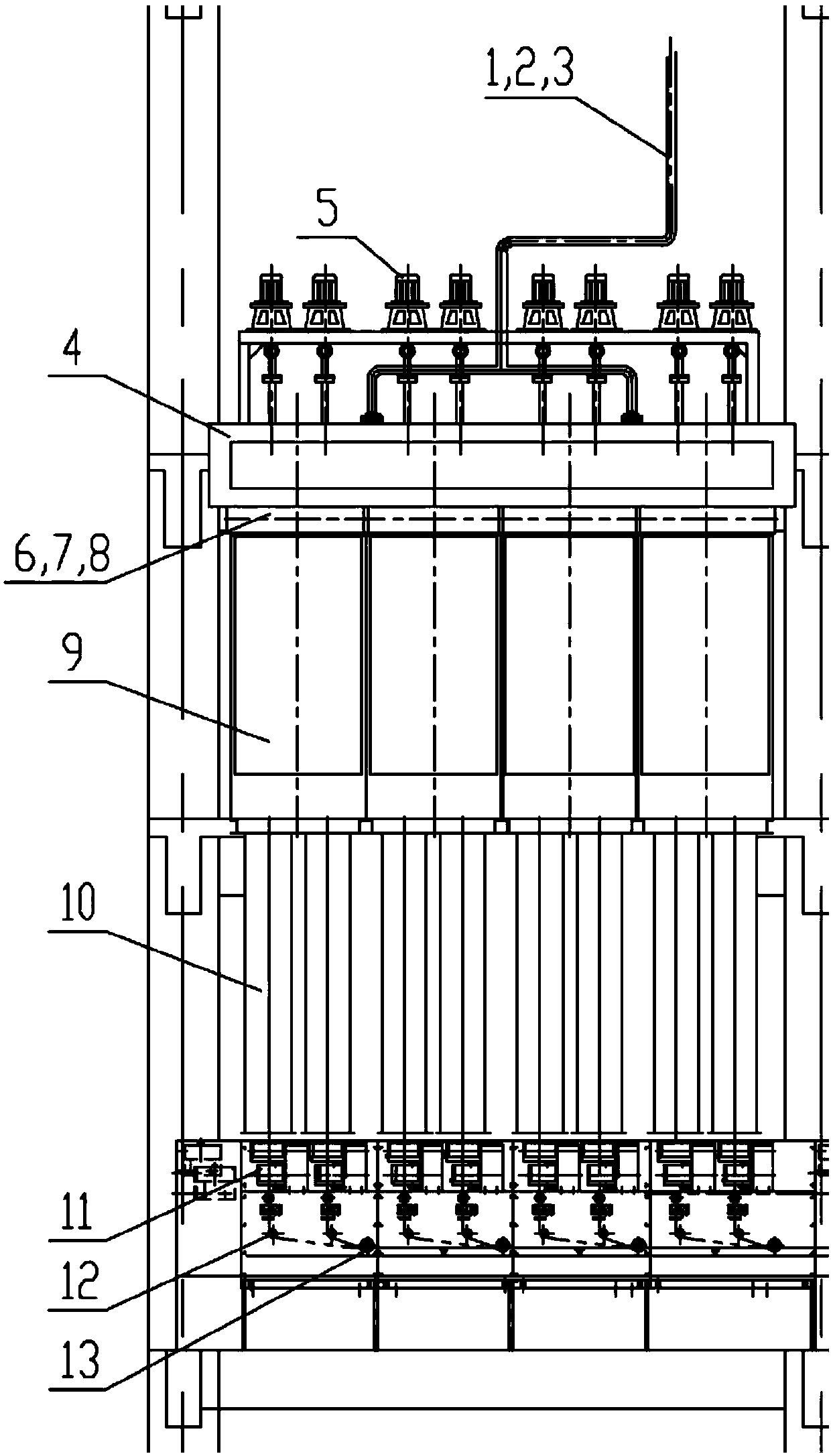

[0031] The first embodiment of the present application provides a spinning machine for producing biomass polyamide 56 fibers. The spinning machine includes N spinning subsystems, which are sequentially arranged on the frame of the spinning machine. In each spinning subsystem According to the traveling direction of the tow, a screw extruder 1 is arranged successively, a melt pipeline system 3 connected with the screw extruder 1, the melt pipeline system 3 is connected with M spinning boxes 4, and each spinning box 4 P weaving positions are provided, and each weaving position is provided with a weaving component 6, and each weaving component 6 is connected with a metering pump system 5, and each metering pump system includes two metering pumps, and the spraying of each weaving component 6 A slow cooler part 7 is arranged below the wire plate, and a side blowing cooling part 9 is arranged below each slow cooler 7 parts, and each side blowing cooling part 9 bottom is connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com