High cutting-resistant high-strength and high modulus polyethylene filament and preparation method thereof

A high-strength, high-modulus, polyethylene spinning technology, applied in the direction of single-component polyolefin artificial filament, artificial filament heat treatment, melt spinning, etc., can solve the problem of poor bonding between hard fiber and fiber matrix and fiber cutting resistance In order to achieve the effect of soft hand feeling, long-lasting cutting resistance and stable cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

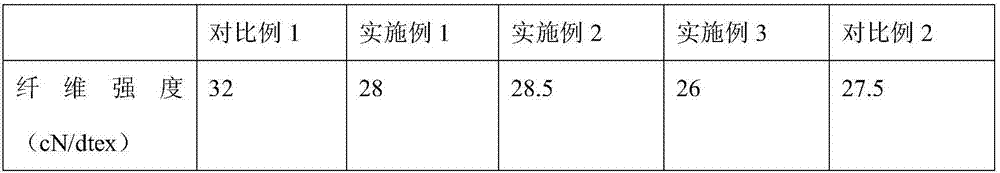

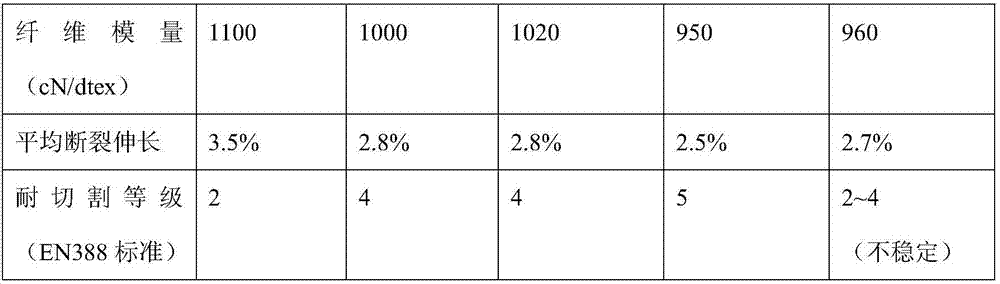

Examples

Embodiment 1

[0036] Using a high-speed blender, 100g of graphene powder with an average particle size of 1um and 1kg of diamond powder with an average particle size of 1um were uniformly dispersed in 5kg of polyethylene powder (IV=3) to prepare a modified premix. The premixed material is conventionally melt-spun to obtain polyethylene wear-resistant polyethylene filaments with a monofilament fineness of 0.56D. Wear-resistant polyethylene filaments are cut into 100um long soft wear-resistant polyethylene staple fibers by cutting machine.

[0037] Put 20 kg of ultra-high molecular weight polyethylene powder (IV=20.5) into 262.5 kg of white oil, stir evenly at 60° C. at a stirring speed of 70 rpm, and obtain an ultra-high molecular weight polyethylene spinning solution. Weigh 5kg of the above-mentioned soft wear-resistant polyethylene short fibers and gradually put them into 50kg of white oil, and use a high-shear emulsifier to stir evenly to obtain a pre-dispersion liquid. The mixer speed is...

Embodiment 2

[0041] Repeat Example 1, except that the combination of wear-resistant powder used to prepare wear-resistant short fibers is 100 g of graphene powder and 1 kg of nitrogen-silicon oxide compound powder.

Embodiment 3

[0043] Repeat Example 2, the difference is that when preparing the modified ultra-high molecular weight polyethylene spinning stock solution, the addition ratio of wear-resistant short fibers is increased to 40% by 20% in Example 2 (that is, 5kg of wear-resistant short fibers made of Add the 55kg white oil pre-dispersion liquid into the 101.25kg spinning stock solution made by 7.5kg ultra-high molecular weight polyethylene powder).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com