PLA and PTT double-component semi-embedded composite fiber and preparation method thereof

A composite fiber, two-component technology, applied in fiber processing, melt spinning, stretch spinning, etc., can solve the problems of poor fiber evenness, decreased composite fiber strength, and fiber strength loss, etc., and achieves spinning speed. High, guaranteed production efficiency, excellent wear resistance and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

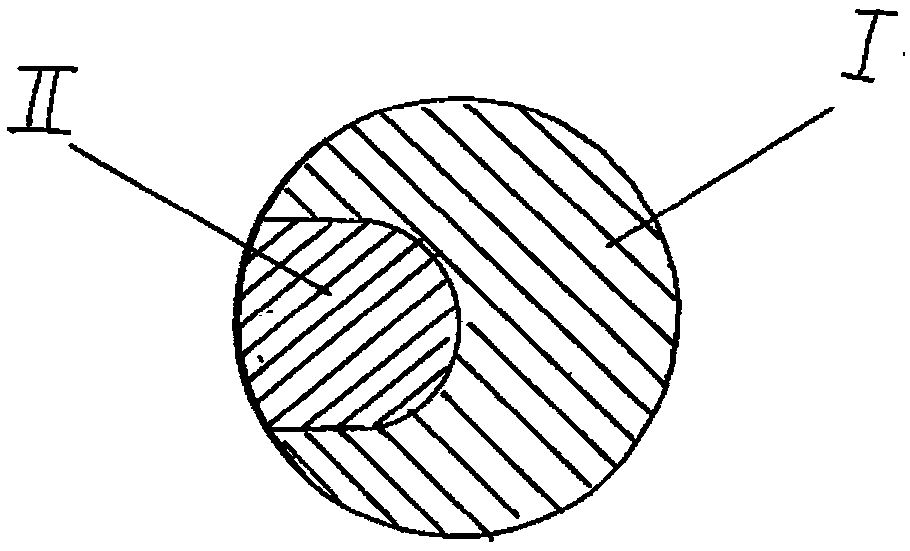

[0029] figure 1 The preparation method of PLA and PTT two-component semi-embedded composite fiber of shown structure comprises the following steps:

[0030] A) Prepare the materials, dry the first component I and the second component II separately to obtain the dried material of the first component I and the dried material of the second component II, wherein: the first component I The drying temperature is 104°C, the drying time is 6h and dried to a moisture content of ≤30PPM, the drying temperature of the second component II is 125°C, the drying time is 10h and dried to a moisture content of ≤50PPM, the first component I is in the composite fiber That is, the mass % ratio in the PLA and PTT two-component semi-embedded composite fiber is 65%, and the second component II accounts for 65% in the composite fiber, that is, in the PLA and PTT two-component semi-embedded composite fiber. The mass % ratio is 35%, the first component I is a PLA chip with an intrinsic viscosity of 1.8...

Embodiment 2

[0045] A) Prepare the materials, dry the first component I and the second component II separately to obtain the dried material of the first component I and the dried material of the second component II, wherein: the first component I The drying temperature is 95°C, the drying time is 8h and dried to a moisture content of ≤30PPM, the drying temperature of the second component II is 135°C, the drying time is 4h and dried to a moisture content of ≤50PPM, the first component I is in the composite fiber That is, the mass % ratio in the PLA and PTT two-component semi-embedded composite fiber is 60%, and the second component II accounts for 60% in the composite fiber, that is, in the PLA and PTT two-component semi-embedded composite fiber. The mass % ratio is 40%, the first component I is a PLA slice with an intrinsic viscosity of 0.8dL / g, and the second component II is a PTT slice with an intrinsic viscosity of 1.3dL / g;

[0046] B) Prepare the spinning melt, melt and extrude the dri...

Embodiment 3

[0049] A) Prepare the materials, dry the first component I and the second component II separately to obtain the dried material of the first component I and the dried material of the second component II, wherein: the first component I The drying temperature is 100°C, the drying time is 7h and dried to a moisture content of ≤30PPM, the drying temperature of the second component II is 130°C, the drying time is 7h and dried to a moisture content of ≤50PPM, the first component I is in the composite fiber That is, the mass % ratio in the PLA and PTT two-component semi-embedded composite fiber is 70%, and the second component II accounts for the PLA and PTT two-component semi-embedded composite fiber in the composite fiber. The mass % ratio is 30%, the first component I is a PLA slice with an intrinsic viscosity of 1.3dL / g, and the second component II is a PTT slice with an intrinsic viscosity of 0.9dL / g;

[0050] B) Prepare the spinning melt, melt and extrude the dried material of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com