SMS-type non-woven fabric manufacture method, SMS-type non-woven fabric and application thereof

A manufacturing method and technology of non-woven fabrics, applied in the direction of melt spinning, textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor air permeability of PE film, easy to cause gynecological diseases, affect women's sense of use, etc., and meet the needs of ensuring health , to ensure the effect of ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

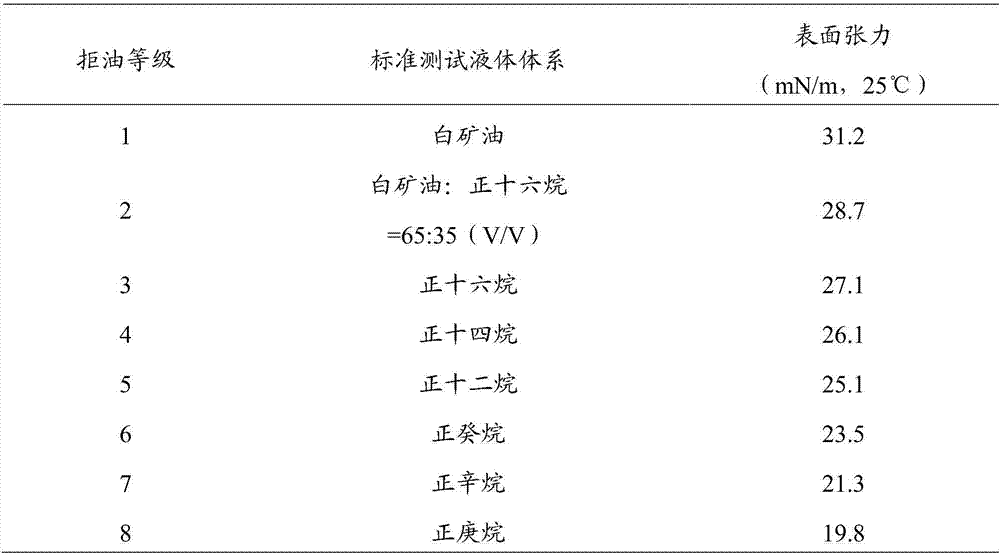

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (1) Preparation of spunbonded fiber web

[0044] Add the spunbond raw material polypropylene and spunbond masterbatch to the two S-die heads according to the above ratio. The mixed and stirred raw materials are sucked into the screw extruder by vacuum suction through the feeding system, and extruded and melted under the condition that the melting temperature of the screw is 180°C-270°C to obtain a hot melt. Subsequently, under the condition of operating temperature of 230-250°C and pressure of 5-10MPa, the hot melt is filtered, metered and distributed through a filtration system and a metering pump. The distributed hot melt is sprayed out through a spinneret with a hole diameter of 0.3-0.8mm, and cooled by a side cooling system with a temperature of 10-20°C and a wind speed of 0.2-1.5m / s to obtain primary growth filaments. The method of air-flow splitting the primary growth filament, through the bell mouth of the drafter (narrow type), and drafting with the draft speed...

Embodiment 1

[0062] The composition of the spunbond masterbatch used in this embodiment is: 80 parts by weight of polypropylene, 19 parts by weight of fluoropolymer melt additive A, and 1 part by weight of lubricant. Wherein, the fluoropolymer melt additive A is polytetrafluoroethylene with an average molecular weight of 50,000-150,000.

[0063] The composition of the masterbatch for melt-blowing used in this embodiment is: 80 parts by weight of polypropylene, 19 parts by weight of fluoropolymer melt additive B, and 1 part by weight of lubricant. Among them, the fluoropolymer melt additive B is a copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether, the ratio of tetrafluoroethylene and perfluoromethyl vinyl ether is 1:1, and the average molecular weight is 350000-450000, The molecular weight distribution is 2.

[0064] The preparation process of this embodiment is as follows:

[0065] (1) Preparation of spunbonded fiber web

[0066] Add the spunbond raw material polypropylen...

Embodiment 2

[0072] The composition of the spunbond masterbatch used in this embodiment is: 65 parts by weight of polypropylene, 34.5 parts by weight of fluoropolymer melt additive A, and 0.5 parts by weight of lubricant. Among them, the fluoropolymer melt additive A is a copolymer of tetrafluoroethylene and vinylidene fluoride, the ratio of tetrafluoroethylene to vinylidene fluoride is 2:1, the average molecular weight is 350,000-500,000, and the molecular weight distribution is 2.5.

[0073] The composition of the masterbatch for melt-blowing used in this embodiment is: 85 parts by weight of polypropylene, 13.5 parts by weight of fluoropolymer melt additive B, and 1.5 parts by weight of lubricant. Among them, the fluoropolymer melt additive B is a copolymer of tetrafluoroethylene and hexafluoropropylene, the ratio of tetrafluoroethylene and hexafluoropropylene is 2:1, the average molecular weight is 250,000-350,000, and the molecular weight distribution is 3.

[0074] The preparation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com