Silver paste used for grapheme touch screen, and preparation method thereof

A graphene, touch screen technology, used in cable/conductor manufacturing, instruments, electrical digital data processing, etc., to achieve long operating time, superior conductivity, and good printing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

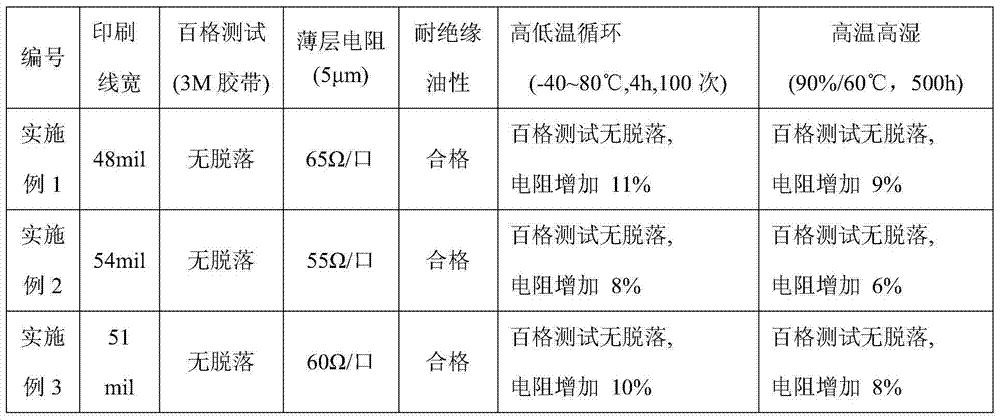

Embodiment 1

[0027] First, 96 kg of modified polyimide with a molecular weight of 20,000 to 30,000 and 224 kg of ethylene glycol diglycidyl ether were heated and stirred at 60°C to make them uniform, and then vacuumed and defoamed for 12 minutes under the condition of a vacuum degree of -0.01 MPa to prepare the Organic carrier; add 450kg flake silver powder with a particle size of 4-7μm, 140kg spherical silver powder with a particle size of 1-3μm, 5kg graphene with a particle size of 50nm-5μm, 10kg organic silicon, 10kg 10kg of hydrogenated castor oil, 10kg of phthalate coupling agent, 10kg of hindered phenolic antioxidant and 35kg of diethylene glycol ethyl ether acetate, using three-dimensional mixing technology, through the shear force generated by revolution and rotation, to achieve Mix thoroughly and evenly; finally use a three-roll machine to grind for 2 to 3 times, and after the fineness reaches 5 μm, vacuum defoam for 13 minutes.

Embodiment 2

[0029] First, heat and stir 68kg of polyacrylate with a molecular weight of 20,000 to 30,000, 40kg of vinyl acetate resin with a molecular weight of 20,000 to 30,000, and 162kg of DBE at 80°C, and then vacuumize and degas under the condition of a vacuum of -0.05MPa8 390kg of flake silver powder with a particle size of 4-7μm, 230kg of spherical silver powder with a particle size of 1-3μm, 10kg of graphene with a particle size of 50nm-5μm, 9kg of organic silicon, 1kg 3kg of fumed silica, 11kg of silane coupling agent, 6kg of TNPP, 30kg of isophorone, and 40kg of ethyl methanol, using three-dimensional mixing technology, through the shear force generated by revolution and rotation, to achieve full mixing and uniformity; finally Use a three-roll machine to grind 2 to 3 times, and after the fineness reaches 5 μm, vacuum defoam for 18 minutes.

Embodiment 3

[0031] First, heat and stir 72kg of unsaturated polyester with a molecular weight of 20,000 to 30,000, 50kg of diol diglycidyl ether, 80kg of DBE, and 38kg of diethylene glycol ethyl ether acetate at 70°C, and then vacuum it at -0.02MPa Under the conditions of vacuum degassing for 15 minutes, it is prepared as an organic carrier; then add 480kg of flake silver powder with a particle size of 4-7μm, 200kg of spherical silver powder with a particle size of 1-3μm, and 5kg of graphite with a particle size of 50nm-5μm ene, 2kg of carbon nanotubes with a particle size of 50nm to 200nm, 10kg of silicones, 10kg of 8kg of polyamide wax, 10kg of phthalate coupling agent, 5kg of phosphite and 30kg of isophorone, using three-dimensional mixing technology, through the shear force generated by revolution and rotation, fully mixed evenly; finally Use a three-roll machine to grind 2 to 3 times, and after the fineness reaches 5 μm, vacuum defoam for 12 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com