Preparation method of bismuth lead sulfide ore flotation inhibitor and use method of inhibitor

A technology for sulfide ore and inhibitor, which is applied in flotation, solid separation and other directions, can solve the problems of inability to inhibit bismuth and lead minerals, high production and processing costs, and high beneficiation costs, and achieves a wide range of pH applications, low environmental pollution, and low price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 15 parts of chloroacetic acid, 40 parts of imidazole, 40 parts of carbon disulfide, and 33 parts of ethanol into a container equipped with a stirrer and a thermometer. Mix and stir. After fully dissolving, heat it in a water bath to 45°C. After 3 hours of reaction, cool and crystallize, and the obtained product is It is the flotation inhibitor of the bismuth lead sulfide ore.

Embodiment 2

[0052] 1. Raw material

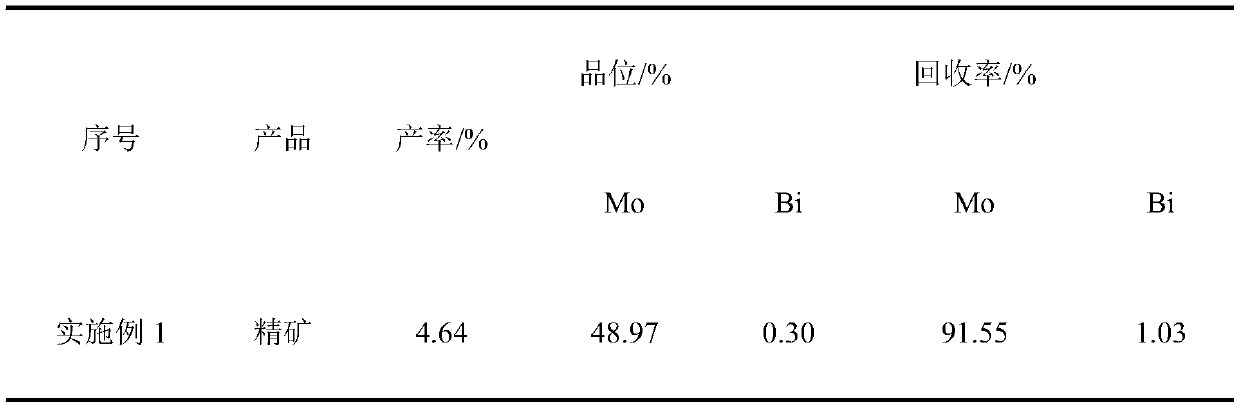

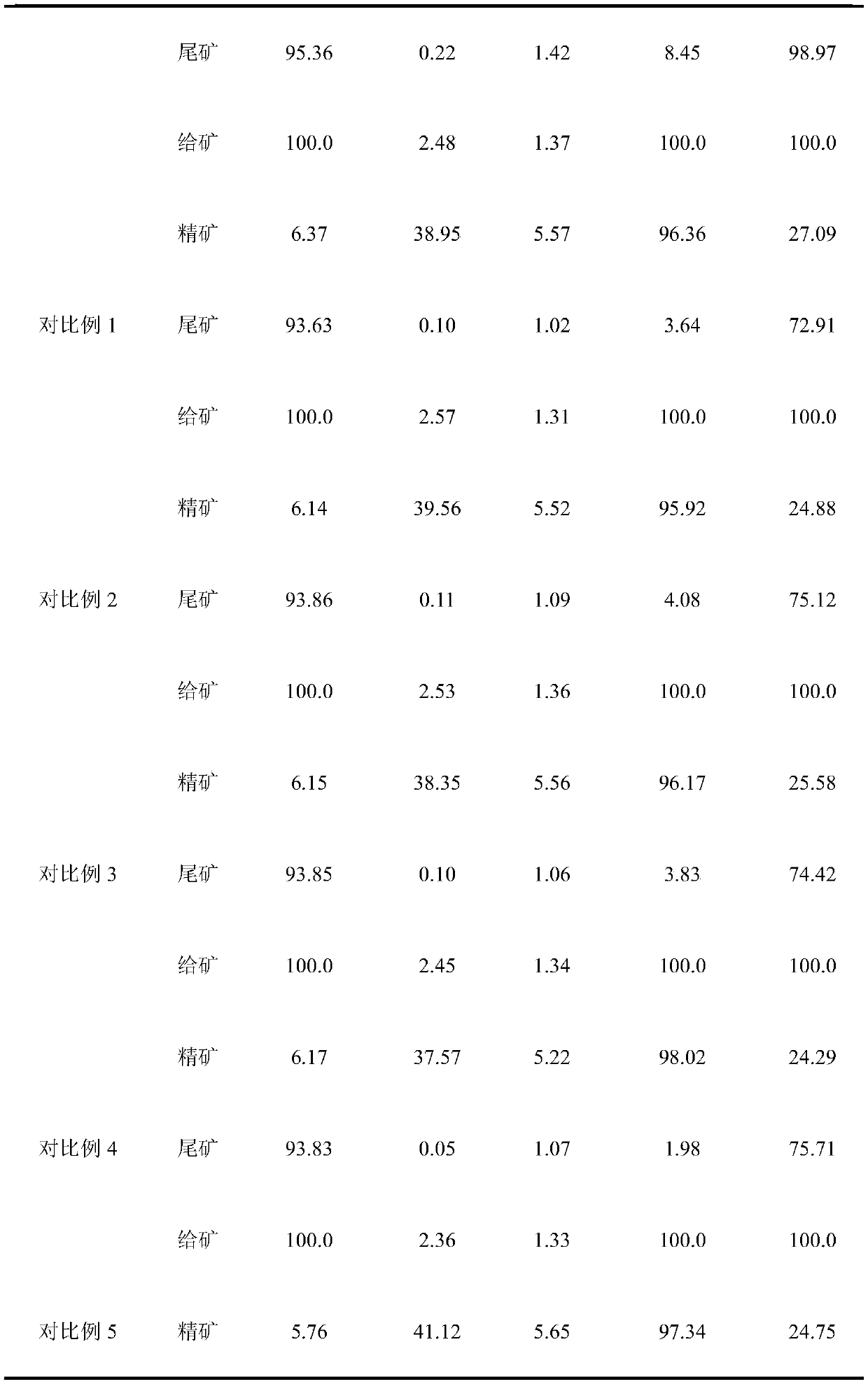

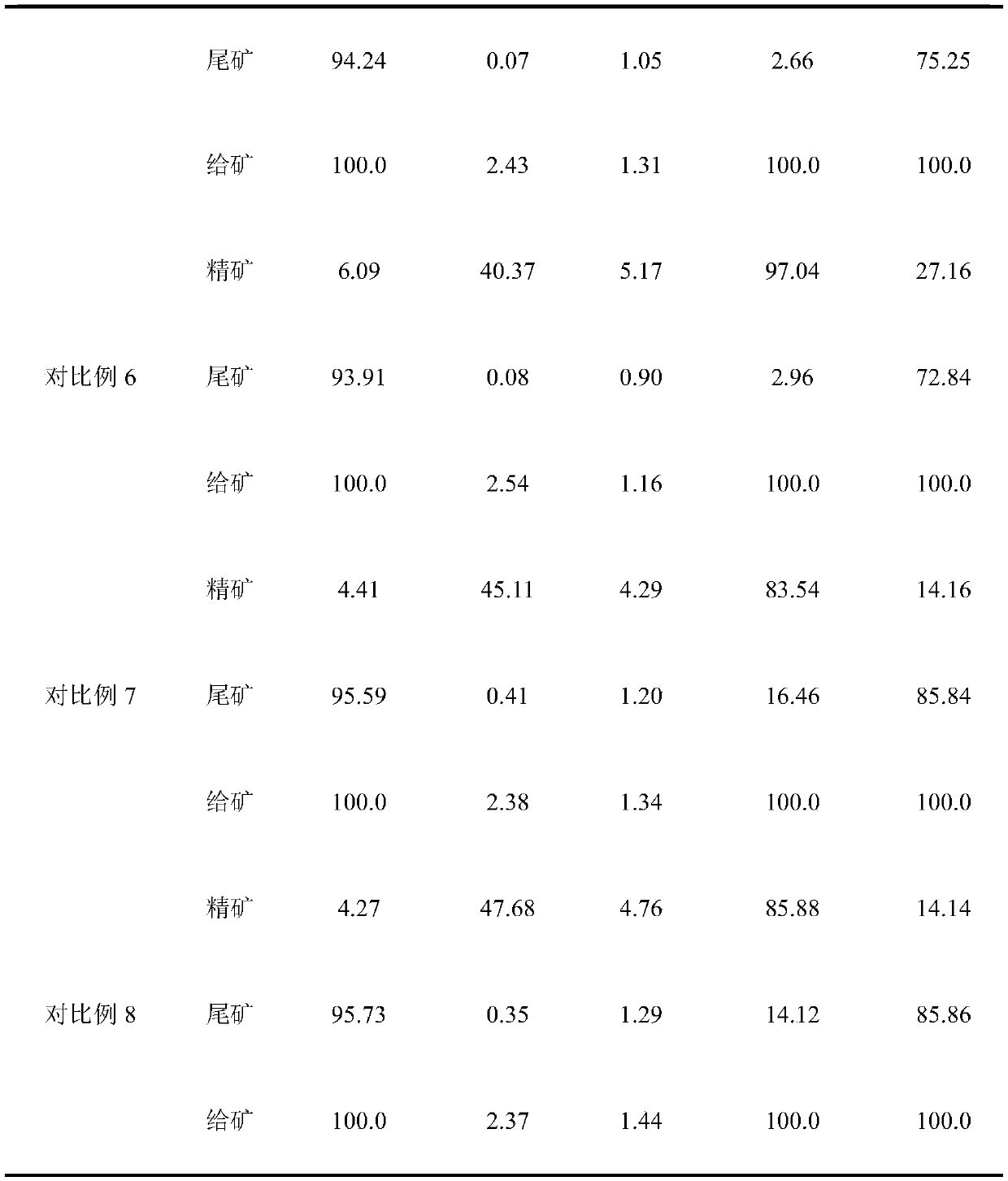

[0053]The mineral raw material is molybdenum-bismuth mixed coarse concentrate, and the phase analysis results show that the main molybdenum-containing mineral in the mineral is molybdenite, and the main bismuth-containing mineral is bismuthite, with a fineness of -200 mesh accounting for 80-85%. The inhibitor used is the inhibitor obtained in Example 1 and Comparative Examples 1-8.

[0054] 2. Operation steps are technical conditions

[0055] Take 1 kg of mixed coarse concentrate and add water to adjust the slurry concentration to 25-35%, add the 500g / t flotation inhibitor, stir for 3-5 minutes, add 100g / t kerosene and 25g / t 2# oil, and then Carry out roughing operations to obtain rough concentrates and tailings; add 120g / t flotation inhibitor to the rough concentrates, and perform 5 times of concentration operations after 3 to 5 minutes of chemical action, and add 50g / t flotation inhibitors to the roughed tailings For kerosene, two sweeping operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com