Method for preparing barium - plumbum - bismuth - oxygen superconduct, and electronic material

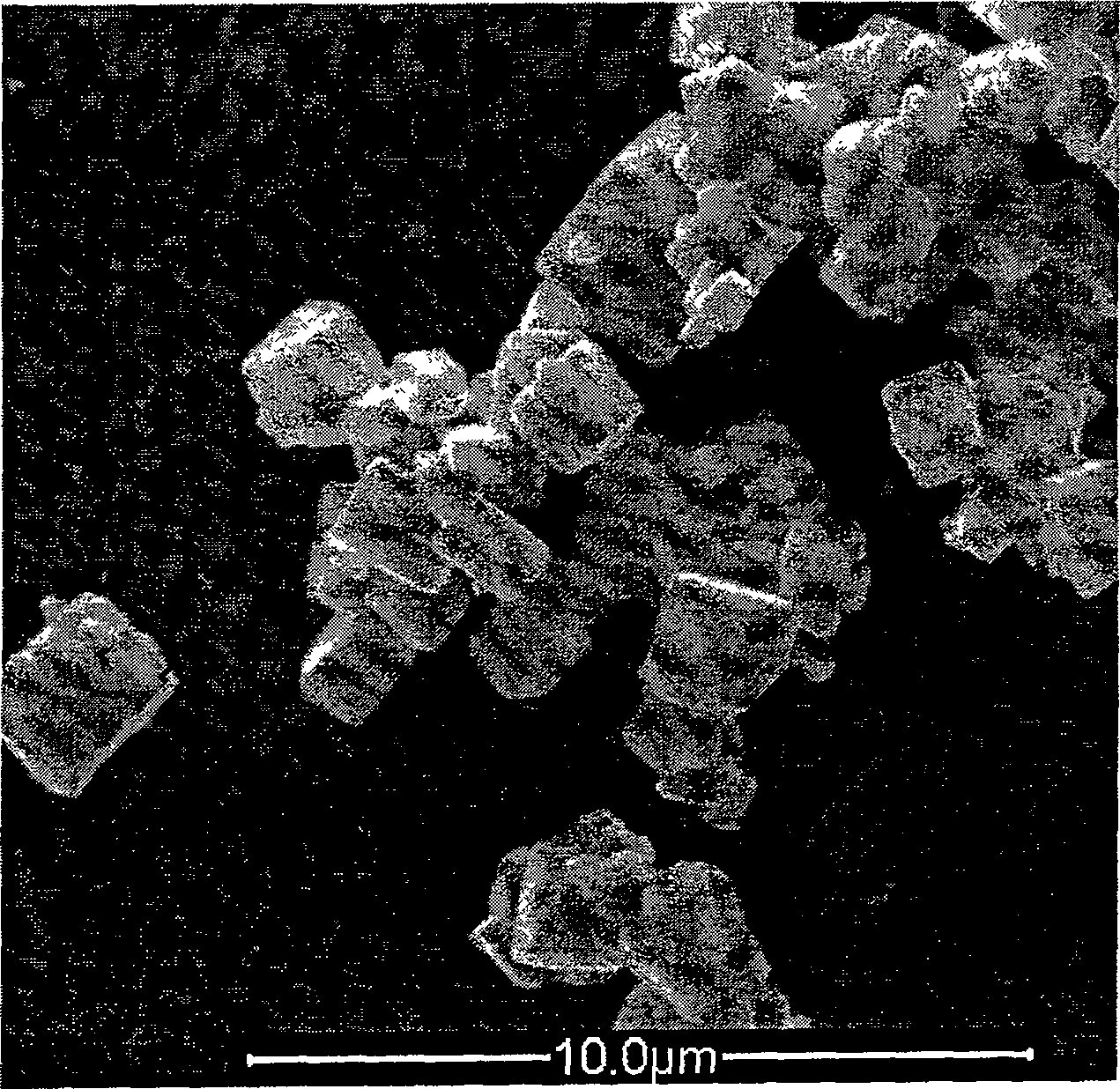

An electronic material, lead-bismuth technology, applied in the field of preparation of superconducting and electronic materials, can solve the problems that restrict the development and application of BPBO superconducting materials, the superconducting performance cannot meet the requirements, and the reaction between compounds is not sufficient, so as to facilitate industrialization The effect of production, small particle size and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Material selection: according to the preparation of barium lead bismuth oxide BaPb 0.75 Bi 0.25 o 3 (i.e. BaPb 1-x Bi x o 3 ,, x=0.25) the stoichiometric ratio of the superconducting material, that is, weigh the raw material barium hydroxide (Ba(OH) 2 ·8H 2 O), sodium bismuthate (NaBiO 3 2H 2 O), bismuth trioxide (Bi 2 o 3 ), lead tetraoxide (Pb 3 o 4 ), where NaBiO 3 2H 2 O and Bi 2 o 3 The molar ratio is 1:1. Grind these raw materials to powder and mix them evenly to make mixed raw materials; another mixture of potassium nitrate and sodium nitrate with a molar ratio of 1:1 is selected as molten salt, molten salt and BaPb that can be prepared 0.75 Bi 0.25 o 3 The molar ratio of the molten salt is 15:1, mix the molten salt with the mixed raw material evenly, and fill it into the reactor.

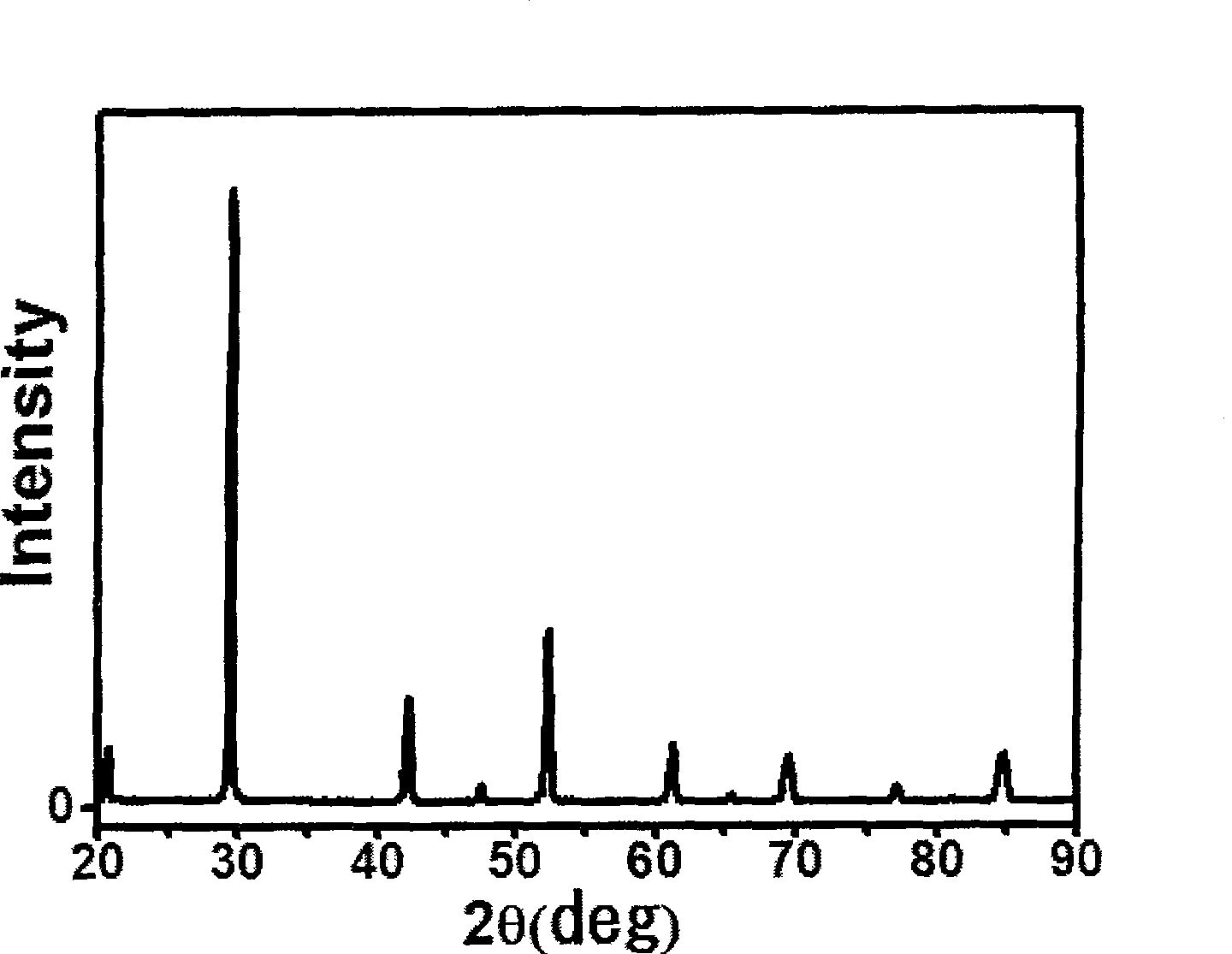

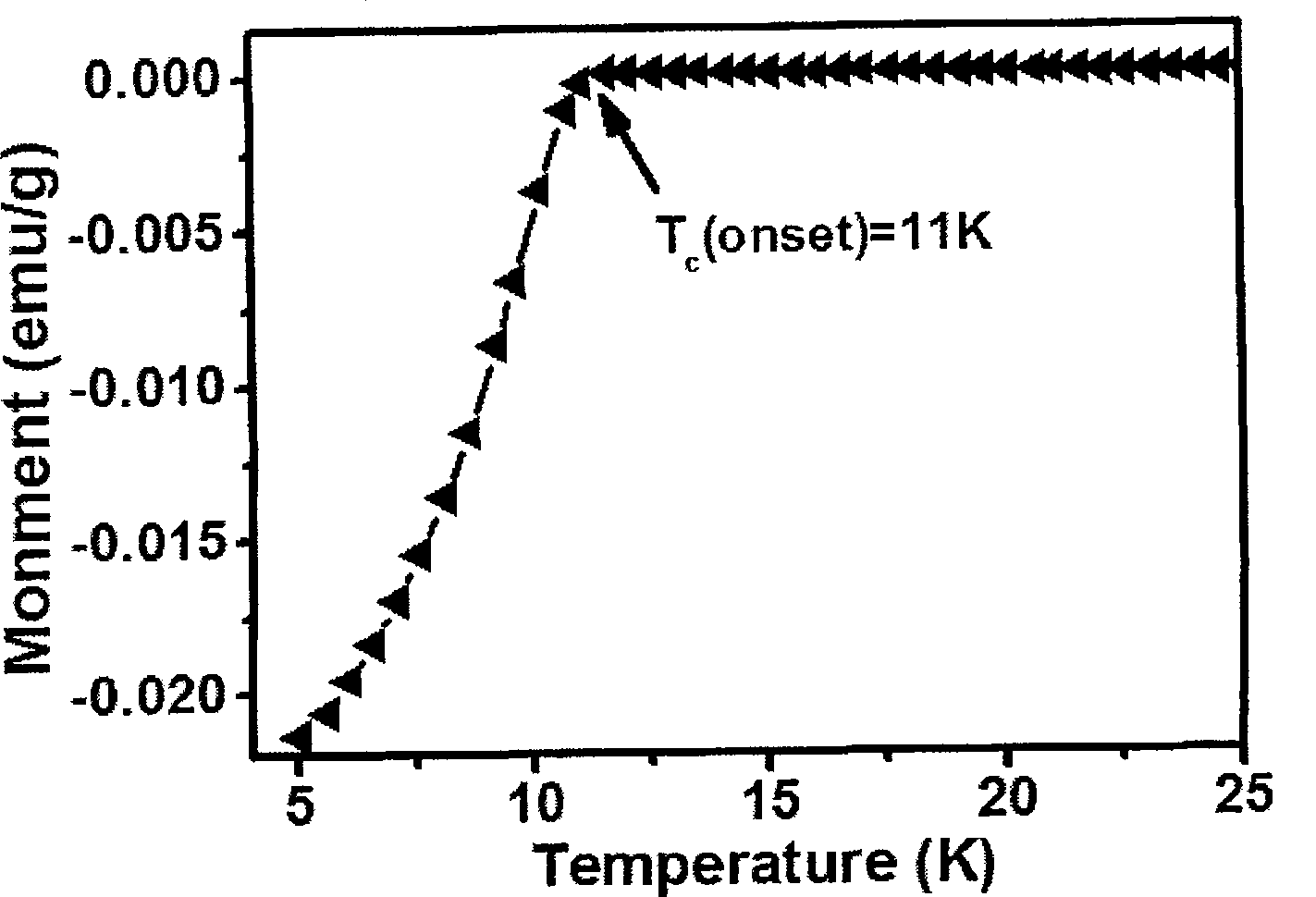

[0019] b. Sintering: Mix the mixed raw materials and molten salt evenly, put them into a Pyrex glass beaker reactor, put them into a box-type electric furnace an...

Embodiment 2

[0023] This example is basically the same as Example 1, the difference is only:

[0024] NaBiO 3 2H 2 O and Bi 2 o 3 The molar ratio is 0.5:1, the molten salt and the BaPb that can be prepared 0.75 Bi 0.25 o 3 The molar ratio is 20:1, grind and mix evenly, put it into a Pyrex glass beaker reactor, then keep it at 150°C for 1.5 hours to remove moisture, then sinter at 600°C for 10 hours, cool to room temperature, and use Rinse four times with hot distilled water, then rinse twice with alcohol, and then dry at 100°C for 20 hours to obtain a black barium lead bismuth oxide superconducting powder material. Experiments have proved that the chemical formula of the prepared barium-lead-bismuth-oxygen superconducting powder material is BaPb 0.75 Bi 0.25 o 3 , the superconducting transition temperature is 10.5K.

Embodiment 3

[0026] This example is basically the same as Example 1, the difference is only:

[0027] NaBiO 3 2H 2 O and Bi 2 o 3 The molar ratio is 2:1, the molten salt and the BaPb that can be prepared 0.75 Bi 0.25 o 3 The molar ratio is 10:1, grind and mix evenly, put it into a Pyrex glass beaker, then keep it warm at 200°C for 3 hours to remove moisture, then sinter at 500°C for 15 hours, cool to room temperature, and use hot distilled water first Rinse five times, then rinse twice with alcohol, and then dry at 150° C. for 30 hours to obtain a black barium lead bismuth oxygen superconducting powder material. Experiments have proved that the chemical formula of the prepared barium-lead-bismuth-oxygen superconducting powder material is BaPb 0.75 Bi 0.25 o 3 , the superconducting transition temperature is 10K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com