Treatment method for bismuth anode slime

A treatment method and anode slime technology, applied in the field of bismuth anode slime treatment, can solve the problems of high recovery cost, long process and high consumption, and achieve the effects of low cost, low consumption and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

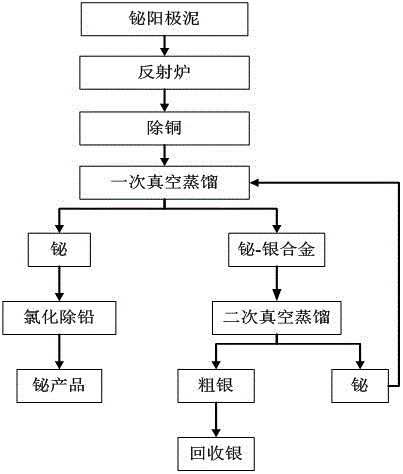

[0018] Such as figure 1 Shown, bismuth anode slime processing method of the present invention is characterized in that comprising the steps:

[0019] a. The reverberatory furnace separates antimony white and coarse bismuth, puts the bismuth anode slime into the reverberatory furnace for refining for 4 days, and separates the Sb 2 o 3 More than 70% antimony white finished products, and then release the bottom solution to cast coarse bismuth;

[0020] b. Copper removal by coarse bismuth, putting the obtained coarse bismuth into a pot for melting and adding sulfur to remove copper to obtain precious bismuth, and send the copper slag to wet processing;

[0021] c. Vacuum distillation once, put the obtained precious bismuth into a vacuum smelting furnace for distillation, the pressure is -10Pa, the temperature is 900°C, and the gaseous bismuth-lead alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com