Lead-free piezoelectric thin film material and preparing method thereof

A thin film material, lead-free piezoelectric technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as ecological environment and human health hazards, achieve good product quality, stable performance, raw materials rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

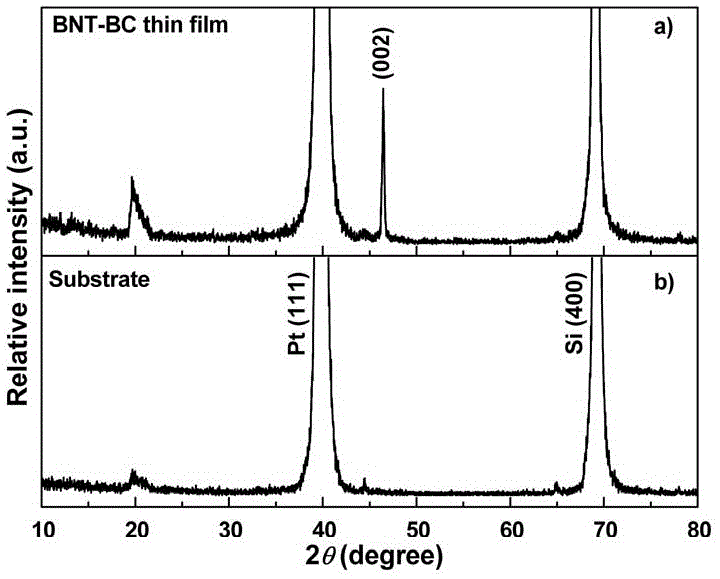

[0033] The chemical structure formula of the lead-free piezoelectric film material of the present invention is (1- x )Bi 0.5 Na 0.5 TiO 3 - x BiCoO 3 , Where x is 0.025, that is, the chemical structure of the lead-free piezoelectric film material is 0.975Bi 0.5 Na 0.5 TiO 3 -0.025BiCoO 3 , Its preparation method includes the following steps:

[0034] A. Preparation of BNT-BC target: solid-phase reaction method is used to prepare BNT-BC target, specifically:

[0035] (1) According to 0.975Bi 0.5 Na 0.5 TiO 3 -0.025BiCoO 3 The stoichiometric stoichiometry in the chemical formula is the raw material Bi 2 O 3 , NaCO 3 , TiO 2 And Co 2 O 3 , In order to prevent the volatilization of Bi and Na during the film preparation process, when weighing the raw materials, Bi 2 O 3 And NaCO 3 Both need 20% molar excess;

[0036] (2) Put the weighed raw materials in step (1) into a ball mill tank, use ethanol as the medium, and ball mill for 24 hours, and then dry the ball milled slurry at 105°C to obt...

Embodiment 2

[0050] The chemical formula of the lead-free piezoelectric film material of the present invention is 0.985Bi 0.5 Na 0.5 TiO 3 -0.015BiCoO 3 , Its preparation method is the same as in Example 1.

Embodiment 3

[0052] The chemical formula of the lead-free piezoelectric film material of the present invention is 0.97Bi 0.5 Na 0.5 TiO 3 -0.03BiCoO 3 , Its preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive field | aaaaa | aaaaa |

| Dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com