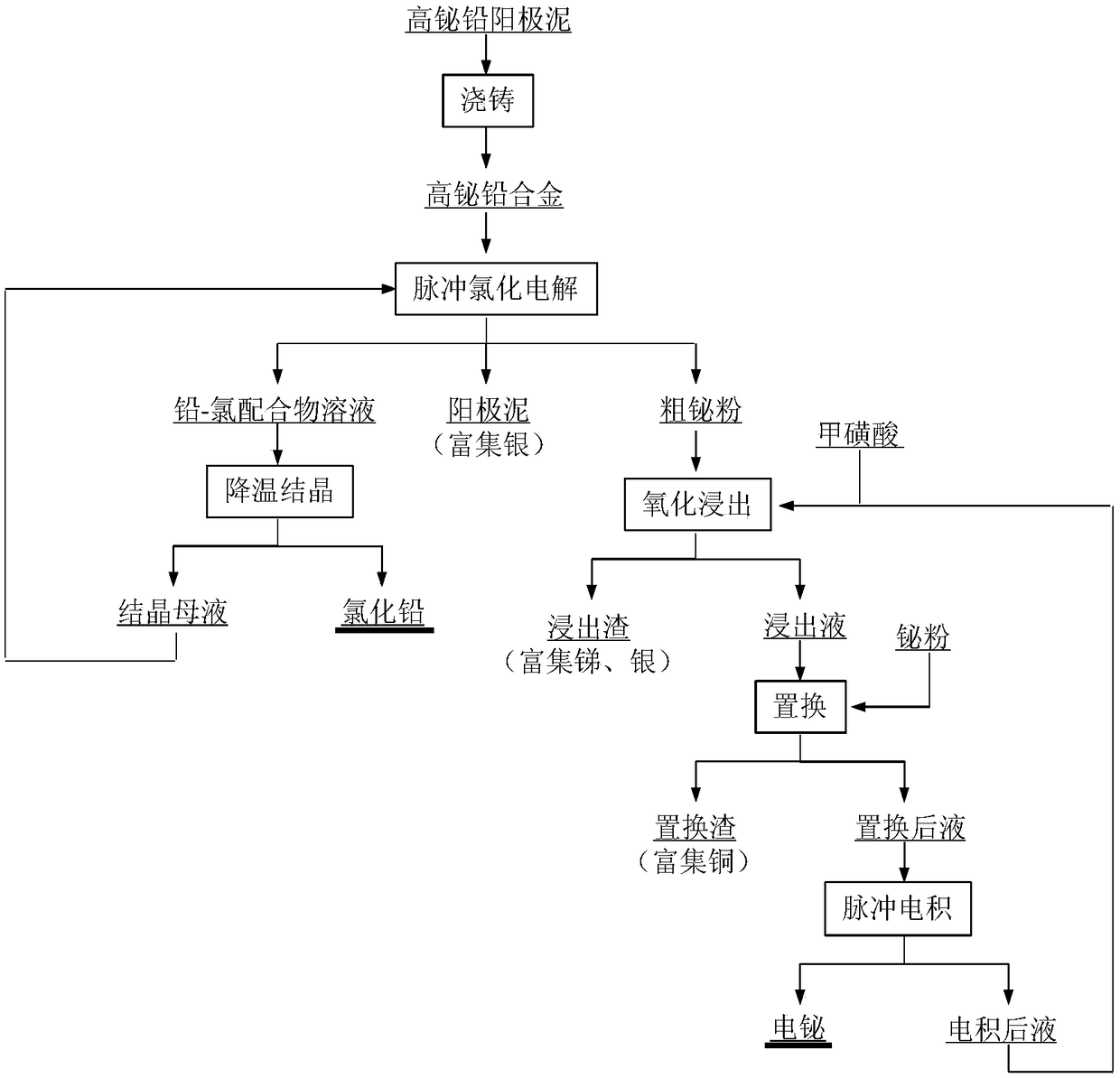

A process for separating lead and bismuth from a high-bismuth-lead alloy

A bismuth-lead alloy and lead separation technology is applied in the directions of photography technology, photography auxiliary technology, and process efficiency improvement, and can solve the problems of easy dispersion of gold and silver, difficult separation, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The composition of the high-bismuth-lead anode alloy cast from high-bismuth-lead anode slime provided by a company in Hunan is: Bi40.1%, Cu 1.9%, Pb 51.4%, Sb 4.5%, Ag 1.9%.

[0032]The high bismuth-lead alloy was used as the anode (length 12cm×width 8cm×thickness 2cm), graphite was used as the cathode for pulse chlorination electrolysis in the HCl-NaCl system, and the anode was placed in a canvas anode bag. The pulse frequency of the pulsed electric field during electrolysis is 500Hz, the duty cycle is 60%, and the pulse average current density is 700A / m 2 , the temperature is 60°C, the distance between cathode and anode is 6cm, the volume of electrolyte is 1L, the concentration of HCl in the electrolyte is 3mol / L, and the concentration of NaCl is 100g / L. Under these conditions, the reaction was stopped after 10 hours of electrolysis, the liquid and solid were separated, the cathode sponge bismuth powder was rinsed twice with 50 ml of hot water and then dried, and the ...

Embodiment 2

[0035] The composition of the high-bismuth-lead anode alloy cast from high-bismuth-lead anode slime provided by a company in Yunnan is: Bi38.3%, Cu 2.3%, Pb 52.7%, Sb 5.1%, Ag 1.3%.

[0036] This high bismuth lead alloy is used as the anode (length 18cm×width 10cm×thickness 2cm), and the titanium plate is used as the cathode in HCl-NH 4 Pulse chlorination electrolysis was carried out in the Cl system, and the anode was placed in a canvas anode bag. The pulse frequency of the pulse electric field is 1200Hz, the duty cycle is 70%, and the pulse average current density is 600A / m 2 , the temperature is 70°C, the distance between cathode and anode is 7cm, the volume of electrolyte is 1.5L, the concentration of HCl in the electrolyte is 4mol / L, NH 4 Cl concentration is 80g / L. Under these conditions, the reaction was terminated after 18 hours of electrolysis, and the liquid and solid were separated. The cathode sponge bismuth powder was washed twice with 100 ml of hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com