A kind of processing technology of high bismuth lead anode slime

A processing technology and anode slime technology, which is applied in the direction of photography technology, photography auxiliary technology, and process efficiency improvement, etc., can solve the problems of high production cost, long production cycle, and occupied capital, etc., and achieve low production cost and production efficiency. High, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

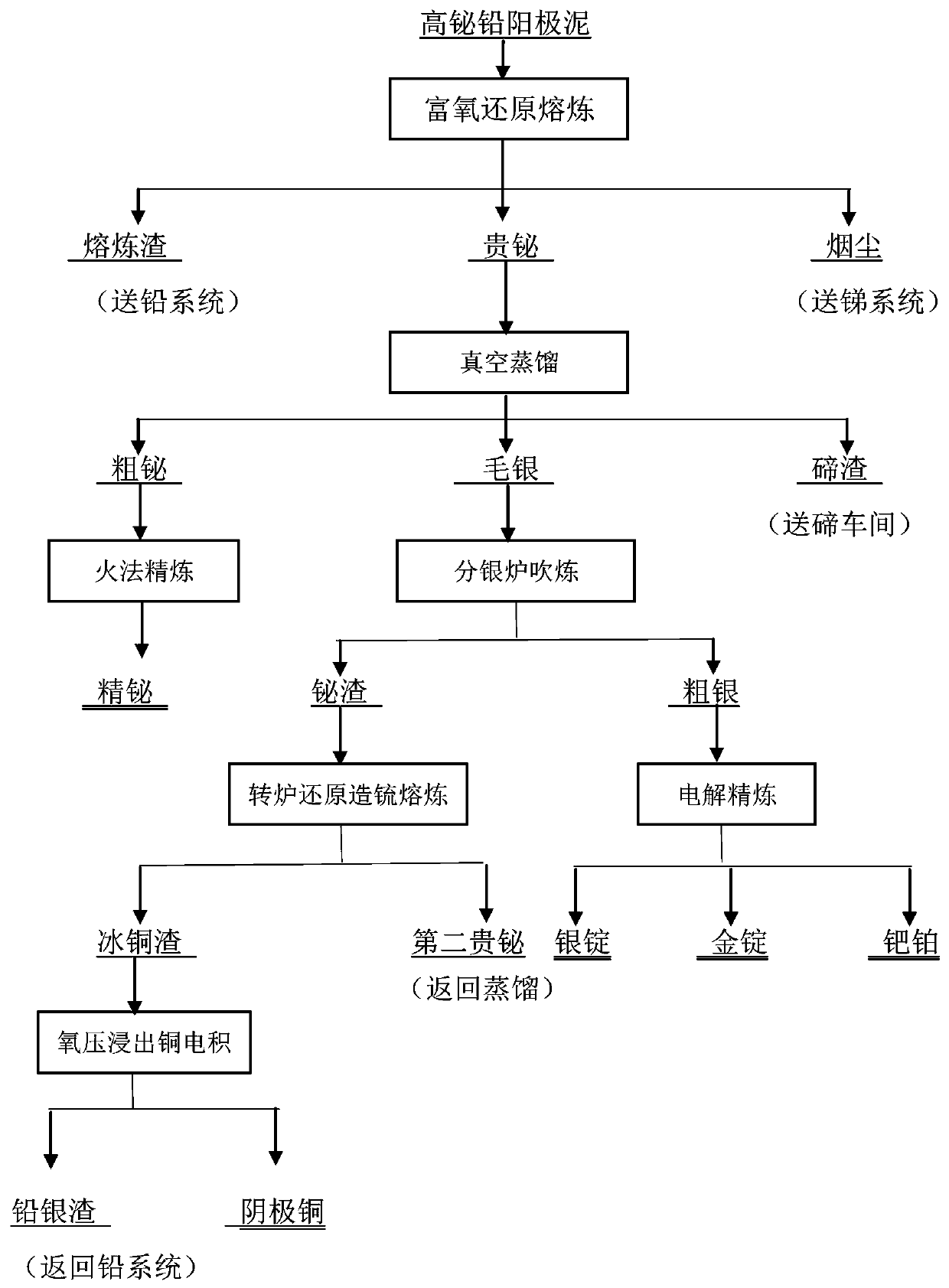

[0021] See attached for detailed process figure 1 ;

[0022] 1. Oxygen-enriched smelting of anode slime

[0023] Anode slime containing Bi 38.29%, Pb 22.74%, Sb 16.96%, Cu 0.91%, Te 0.16%, Ag 27597 (g / t), Au41.3 (g / t) and mixed with 2.5% reduced coal was put into Go to the oxygen side blowing furnace for reduction smelting, adopt the oxygen concentration of 98%, the oxygen pressure of 0.25MPa, and the furnace temperature of 900-950°C to obtain the product noble bismuth alloy, slag and smoke. The slag contains 35.2% Pb, 14.56% Sb, 1.5% Bi, and 524 Ag (g / t). The slag is used as raw material for lead smelting and returned to the lead smelting system to recover valuable metals such as lead, silver, and antimony. The soot contains Sb 61.77%, Pb 8.26%, Bi 2.28%, Ag 635 (g / t), and is sent to the antimony smelting system as the raw material for smelting antimony white; precious bismuth alloy contains Bi 73.92%, Pb 14.55%, and Ag 69811 ( g / t);

[0024] 2. Vacuum distillation of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com