A kind of method that reclaims bismuth in precious lead

A technology of precious lead and bismuth lead, applied in the field of bismuth recycling, can solve the problems of unfavorable clean production and low-carbon economy, high comprehensive treatment cost, low metal recovery rate, etc., achieve great promotion potential, low processing cost, and direct metal recovery high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

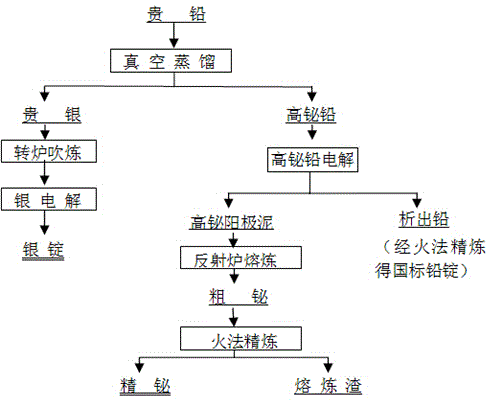

[0023] Such as figure 1 Shown, the method for reclaiming bismuth in this noble lead, its concrete steps are as follows:

[0024] Step 1: First put noble lead (Pb51.0wt.%, Sb14.6wt.%, Cu4.0wt.%, Bi10wt.%, Ag16wt.%) in a vacuum furnace and melt it at a temperature of 450-480°C , and then control the vacuum degree to be 10-20Pa, the temperature to be 940-960°C, and the noble lead feed rate to be 70g / s to separate lead, antimony, bismuth, and copper by vacuum distillation for 25-30 minutes, and produce a high-bismuth lead (Pb64. 3wt.%, Sb15.1wt.%, Cu0.06wt.%, Bi12.5wt.%, Ag2.27wt.%) and precious silver (Pb1.6wt.%, Sb12.7wt.%, Cu17.9wt.%, Bi1.5wt.%, Ag68.1wt.%), the output of the primary high bismuth lead is placed in a vacuum furnace, and then the lead, antimony, bismuth, and copper are separated by vacuum distillation under the above conditions to produce the secondary high bismuth lead Bismuth lead (Pb75.8wt.%, Sb3.56wt.%, Cu0.02wt.%, Bi18.6wt.%, Ag0.009wt.%) and residual pre...

Embodiment 2

[0029] Such as figure 1 Shown, the method for reclaiming bismuth in this noble lead, its concrete steps are as follows:

[0030] Step 1: First place noble lead (Pb50.0wt.%, Sb13.6wt.%, Cu3.6wt.%, Bi13wt.%, Ag18wt.%) in a vacuum furnace and melt at a temperature of 450-480°C , and then control the vacuum degree to be 10-20Pa, the temperature to be 940-960°C, and the noble lead feeding amount to be 70g / s to separate lead, antimony, bismuth, and copper by vacuum distillation for 25-30 minutes, and produce a high-bismuth lead (Pb63. 4wt.%, Sb14.2wt.%, Cu0.053wt.%, Bi14.6wt.%, Ag3.45wt.%) and precious silver (Pb1.3wt.%, Sb11.3wt.%, Cu17.1wt.%, Bi1.42wt.%, Ag69.5wt.%), the output of the primary high bismuth lead is placed in a vacuum furnace, and then the lead, antimony, bismuth and copper are separated by vacuum distillation again under the control of the above conditions to produce the secondary high bismuth lead Bismuth lead (Pb74.6wt.%, Sb2.96wt.%, Cu0.02wt.%, Bi20.3wt.%, Ag0...

Embodiment 3

[0035] Such as figure 1 Shown, the method for reclaiming bismuth in this noble lead, its concrete steps are as follows:

[0036] Step 1: First put noble lead (Pb40wt.%, Sb15.5wt.%, Cu4wt.%, Bi15wt.%, Ag19.8wt.%) in a vacuum furnace and melt it at a temperature of 450-480°C, then Vacuum distillation for 25-30 minutes to separate lead, antimony, bismuth, and copper under the conditions of controlling the vacuum degree of 10-20Pa, the temperature of 940-960°C, and the feeding amount of precious lead at 69-71g / s (grams per second), and the output is once high. Bismuth lead (Pb60.8wt.%, Sb16.4wt.%, Cu0.055wt.%, Bi16.7wt.%, Ag4.1wt.%) and precious silver (Pb1.5wt.%, Sb13.5wt.%, Cu17 .8wt.%, Bi1.66wt.%, Ag66.9wt.%), put the produced primary high-bismuth lead in a vacuum furnace, and then separate lead, antimony, bismuth, copper by vacuum distillation again under the above conditions Output of secondary high bismuth lead (Pb70.8wt.%, Sb3.23wt.%, Cu0.03wt.%, Bi24.1wt.%, Ag0.009wt.%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com