Rare earth doped gallium germanium bismuth lead luminous glass material and its preparation method and uses

A technology of luminescent glass and bismuth lead, which is applied to the application of the above luminescent glass material, the rare earth-doped gallium germanium bismuth lead luminescent glass material, and the preparation field of the above luminescent glass material, can solve the large gap, chemical stability and mechanical strength. Poor, limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

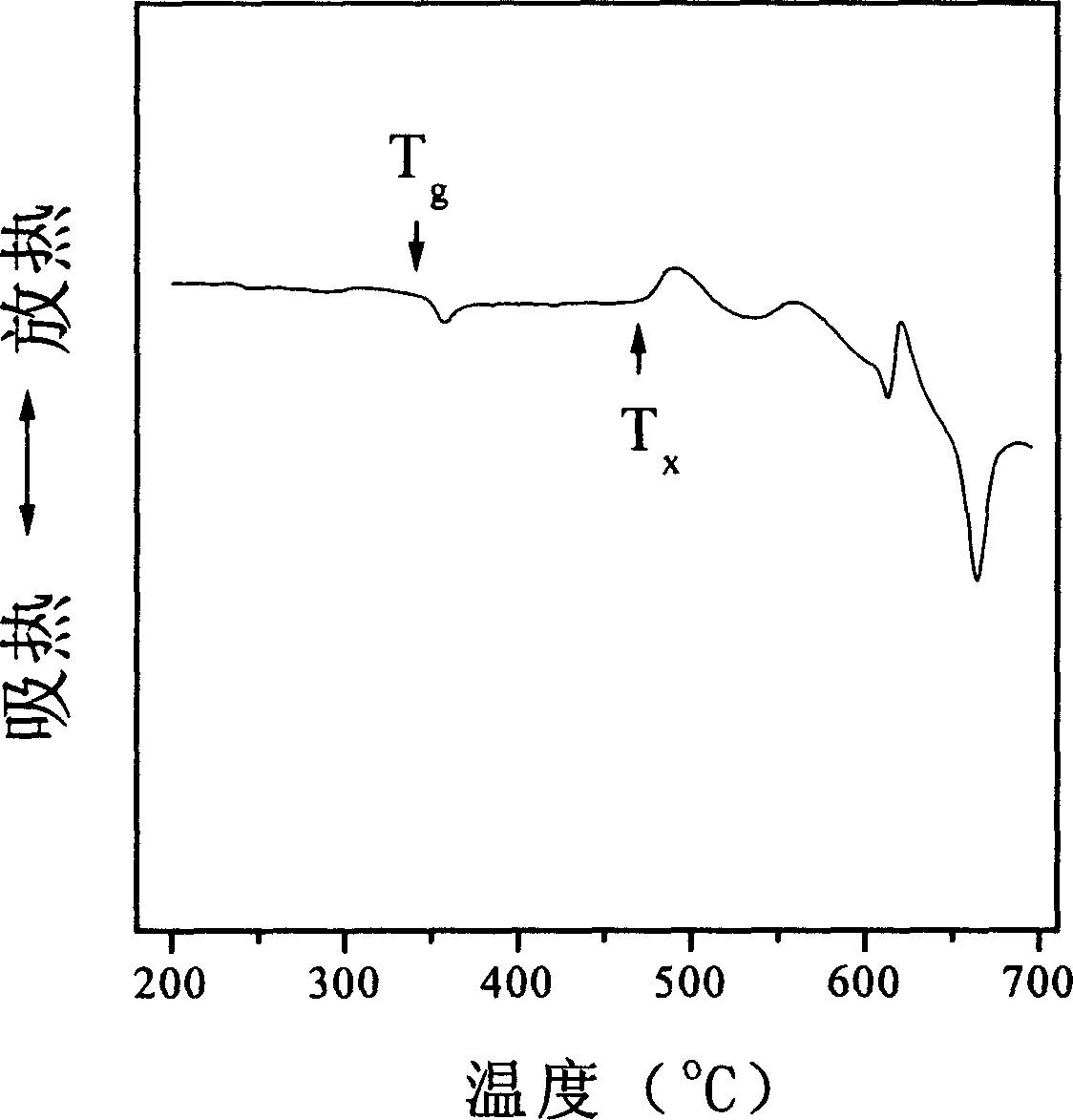

[0042] (1) Weigh 20g of the following mole percentage components, mix them evenly, put them into a covered platinum crucible and place them in a silicon carbon rod electric furnace for melting, the melting temperature is 1100°C, and the melting time is 30 minutes The molten glass is obtained, and after the molten liquid is clarified, it is poured into a preheated stainless steel mold to obtain glass;

[0043] (2) Quickly put the above glass into the material that has been heated to the material transition temperature T g (344° C.) in a muffle furnace for 1 hour, then cool down to 100° C. at a rate of 10° C. / hour, turn off the power, and automatically cool down to room temperature to obtain the luminescent glass material of the present invention.

[0044] Each component and its mole percentage are:

[0045] Ga 2 o 3 0; GeO 2 70; 2 o 3 15; PbO 10;

[0046] PbF 2 5; Er 2 o 3 1.5; Yb 2 o 3 1.0.

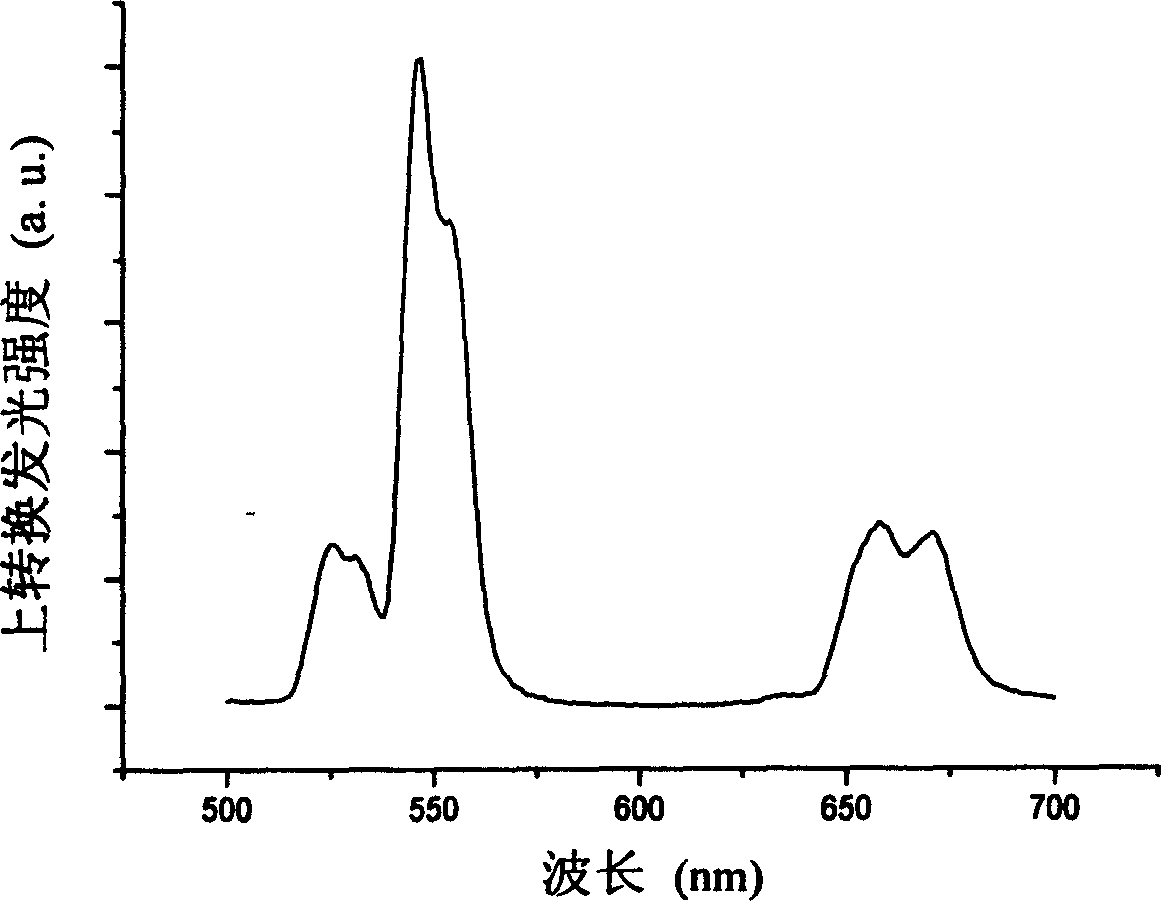

[0047] Take a small part of the sample ...

Embodiment 2

[0050] (1) Weigh 20g of the following mole percentage components, mix them evenly, put them into a covered platinum crucible and place them in a silicon carbon rod electric furnace for melting, the melting temperature is 900°C, and the melting time is 30 minutes The molten glass is obtained, and after the molten liquid is clarified, it is poured into a preheated stainless steel mold to obtain glass;

[0051] (2) Quickly put the above glass into the material that has been heated to the material transition temperature T g (357° C.) in a muffle furnace for 1 hour, then cool down to 100° C. at a rate of 5° C. / hour, turn off the power, and automatically cool down to room temperature to obtain the luminescent glass material of the present invention.

[0052] Each component and its molar content are:

[0053] Ga 2 o 3 30; GeO 2 0; Bi 2 o 3 20; PbO5;

[0054] PbF 2 45;Tm 2 o 3 1.5; Yb 2 o 3 2.

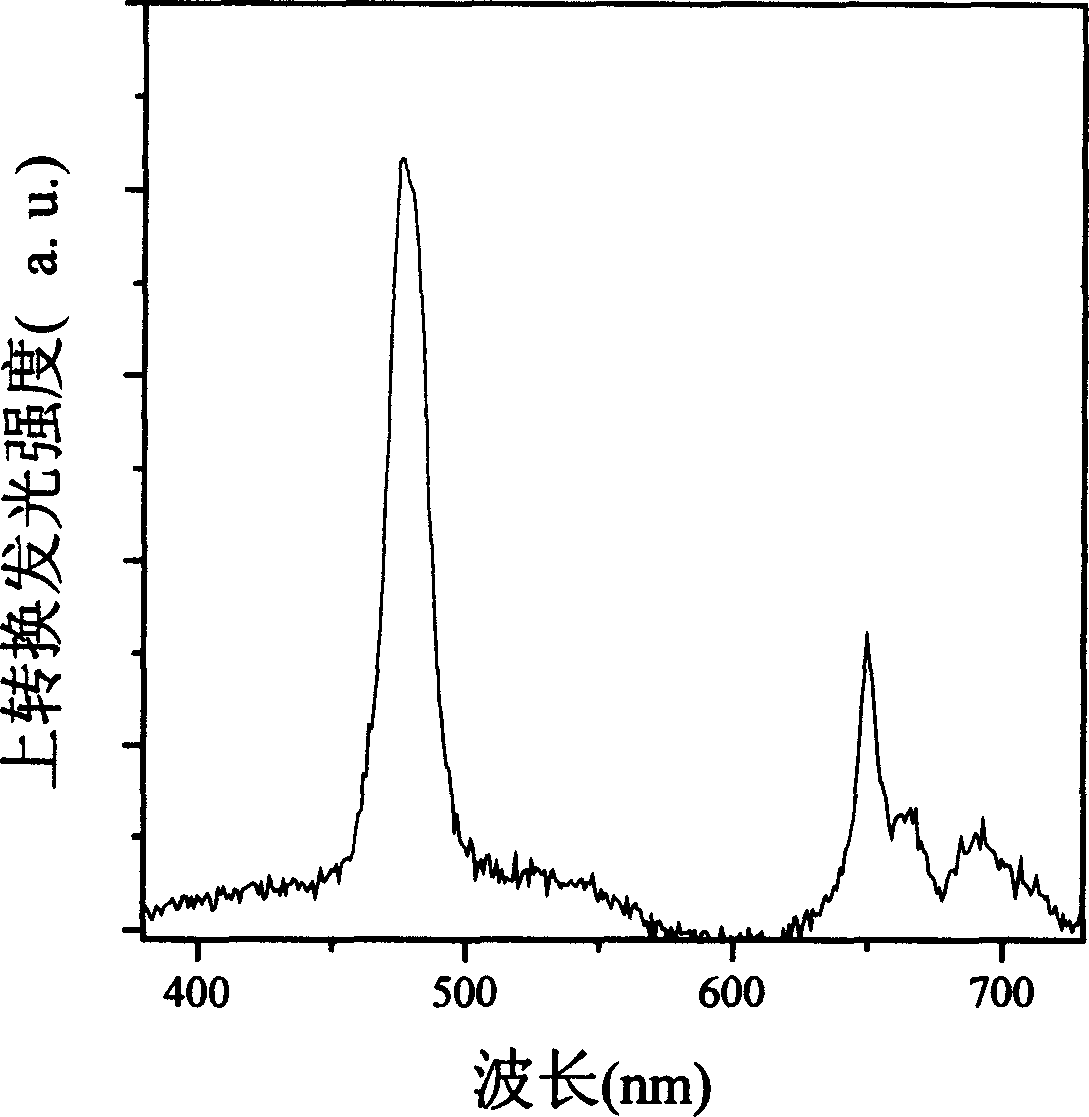

[0055] Take a small part of the sampl...

Embodiment 3

[0058] (1) Weigh 20g of the following mole percentage components, mix them evenly, put them into a covered platinum crucible and place them in a silicon carbon rod electric furnace for melting, the melting temperature is 1000°C, and the melting time is 20 minutes The molten glass is obtained, and after the molten liquid is clarified, it is poured into a preheated stainless steel mold to obtain glass;

[0059] (2) Quickly put the above glass into the material that has been heated to the material transition temperature T g (357° C.) in a muffle furnace for 1 hour, then cool down to 100° C. at a rate of 8° C. / hour, turn off the power, and automatically cool down to room temperature to obtain the luminescent glass material of the present invention.

[0060] Each component and its molar content are:

[0061] Ga 2 o 3 15; GeO 2 20; 2 o 3 50; PbO 15;

[0062] PbF20; Tm 2 o 3 0.2; 2 o 3 2.

[0063] Take the annealed sample and process it into a 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com