Control rod for liquid heavy metal cooling reactor

A liquid heavy metal and reactor technology, applied in the field of reactor equipment, can solve problems such as low density, and achieve the effect of simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

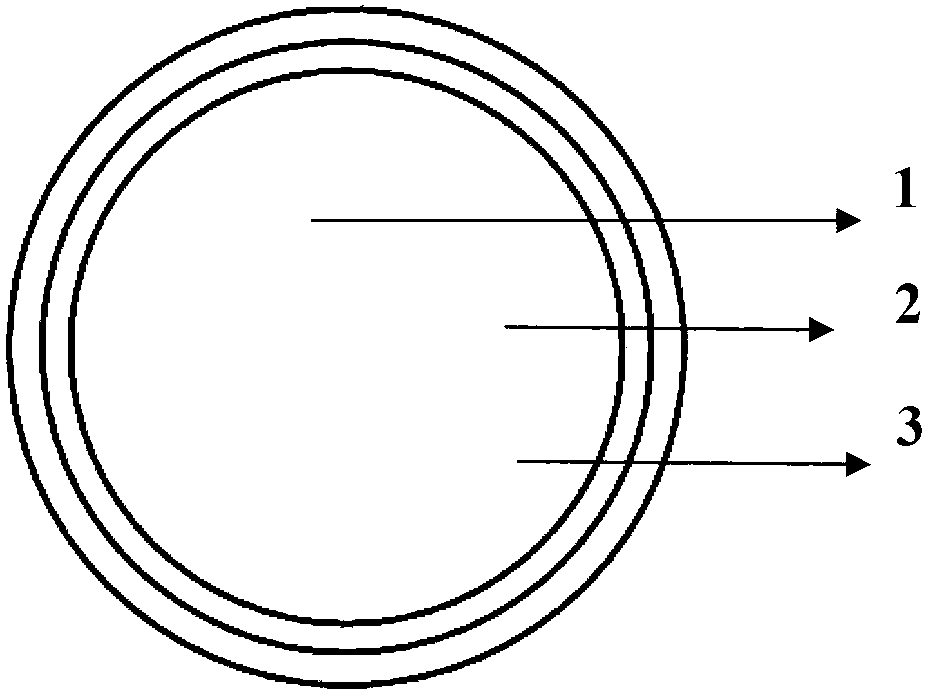

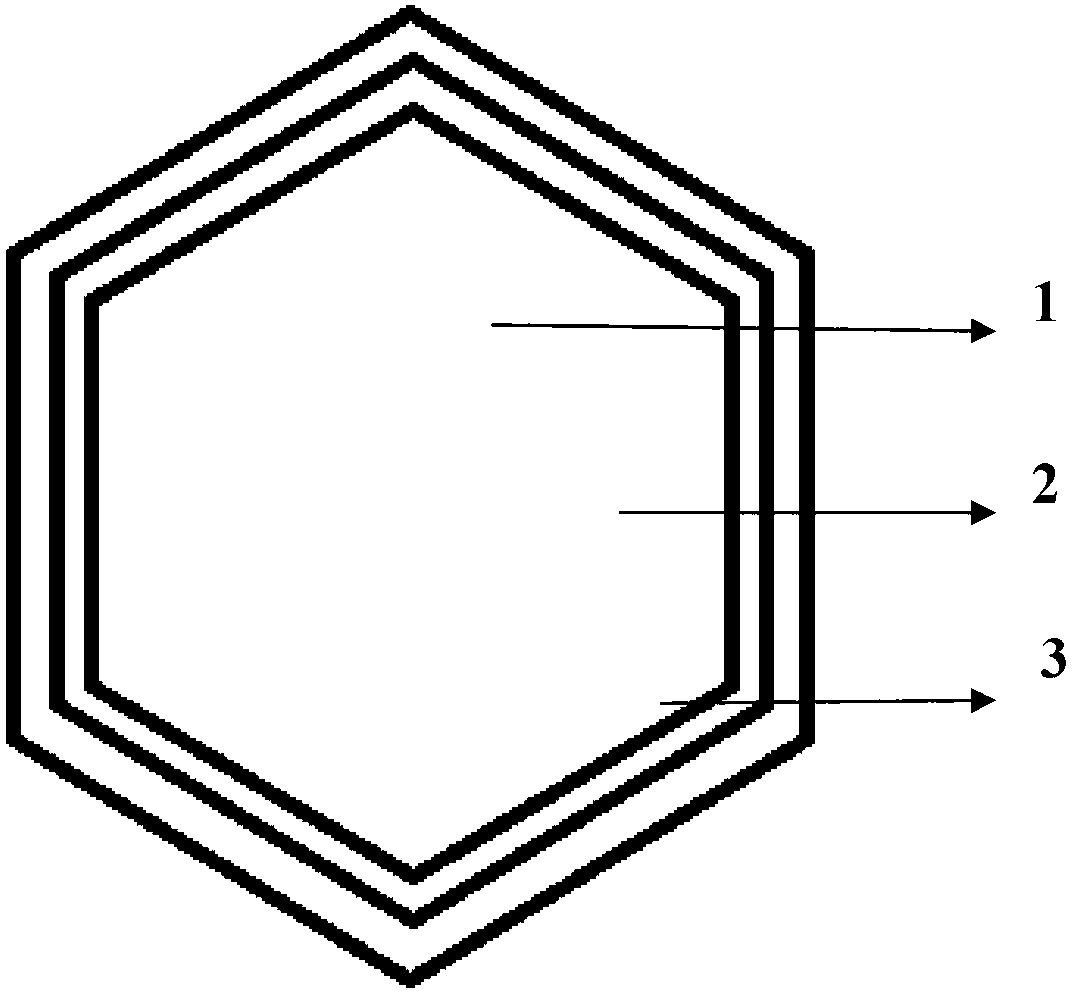

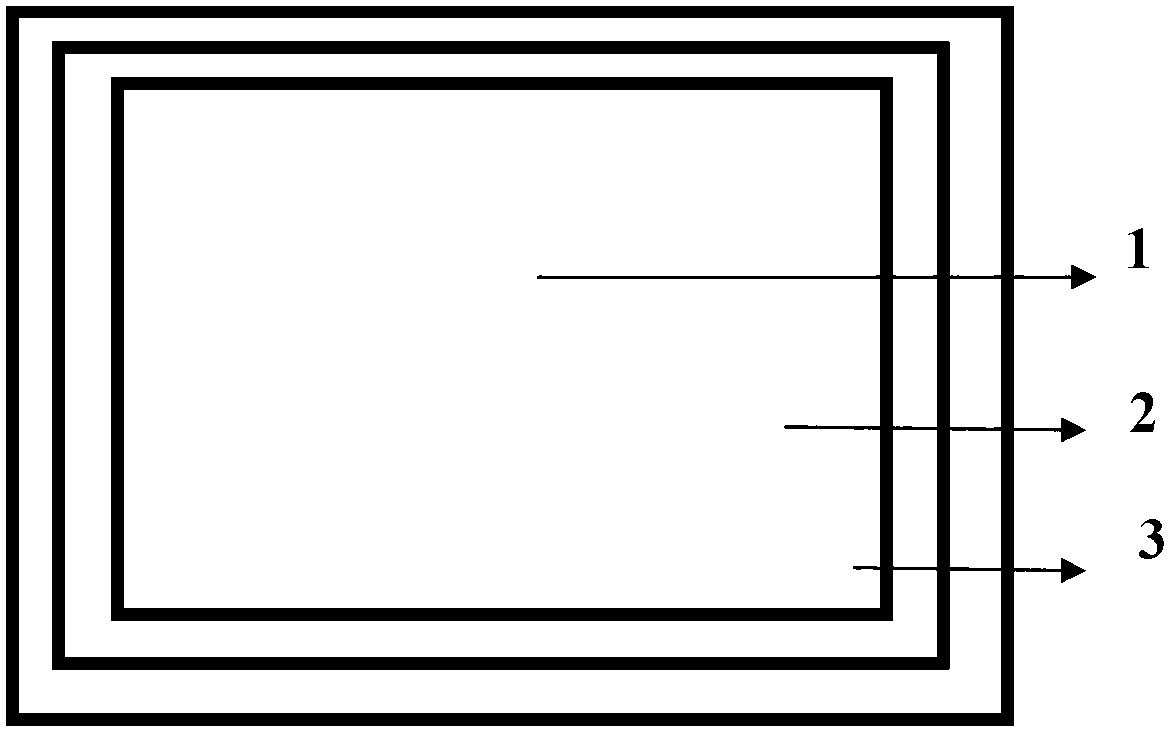

[0023] Such as Figure 1-6 As shown, the present invention proposes a control rod applied to lead-bismuth and lead-cooled reactors, including a high-density absorber 1 (density greater than 10g / cm 3 ), void 2 and cladding 3;

[0024] The high-density absorber 1 is located in the center of the control rod structure and is used to absorb neutrons to meet the requirements of reactivity control and shutdown; the size of the high-density absorber 1 depends on the design requirements of the reactor, and the density of the high-density absorber 1 The density of the high-density absorber 1 is greater than that of lead, bismuth and lead. There are two types of implementations. The first type is a heavy metal absorber, including natural tungsten, natural rhenium or natural tantalum; the second type is a combination of heavy metal absorber and boron carbide. Mixtures, including a mixture of tungsten and boron carbide, a mixture of rhenium and boron carbide, a mixture of tantalum and bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com