Environment-friendly desulfurization extruder of regenerated rubber

A recycled rubber, environmentally friendly technology, applied in the field of recycled rubber extrusion, can solve the problems of high risk, high pressure, high desulfurization labor intensity, etc., and achieve the effect of no waste gas and waste water discharge, no pollution, and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

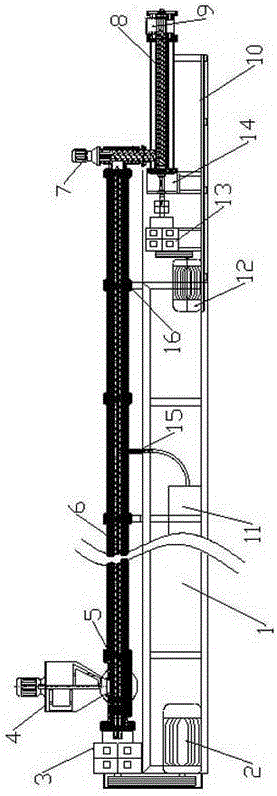

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

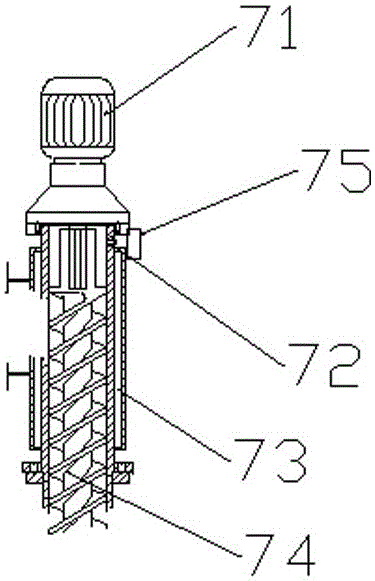

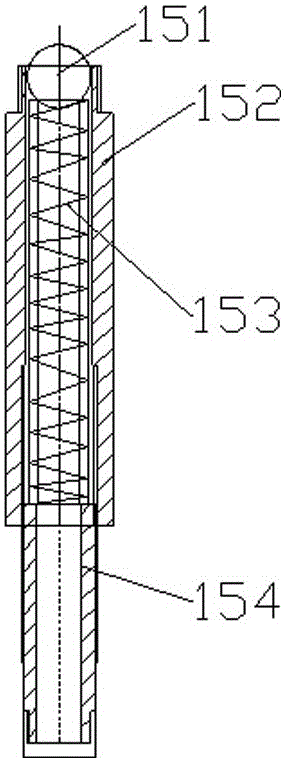

[0026] Environmentally friendly recycled rubber desulfurization extruder, including base 1, upper motor 2, upper gear box 3, feeding device 4, twin-screw feeding device 5, barrel screw 6, over-feeding device 7, twin-screw cooling extrusion 8 and waste recovery device 11, this equipment realizes the fully closed extrusion process from rubber powder to reclaimed rubber so that it will not be in contact with the air, and it is evenly stirred, and the temperature is automatically controlled and adjusted to make the desulfurization effect of reclaimed rubber good, Mooney The rebound is low; the upper motor 2 and the upper gear box 3 are installed on the left side of the base 1, and the twin-screw feeding device 5 is installed on the right end of the upper gear box 3. Sticky material occurs when the material is sticky; the upper part of the twin-screw feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com