Sequencing batch photocatalytic reactor

A photocatalytic reaction and sequencing batch technology, which is applied in chemical instruments and methods, light water/sewage treatment, magnetic separation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

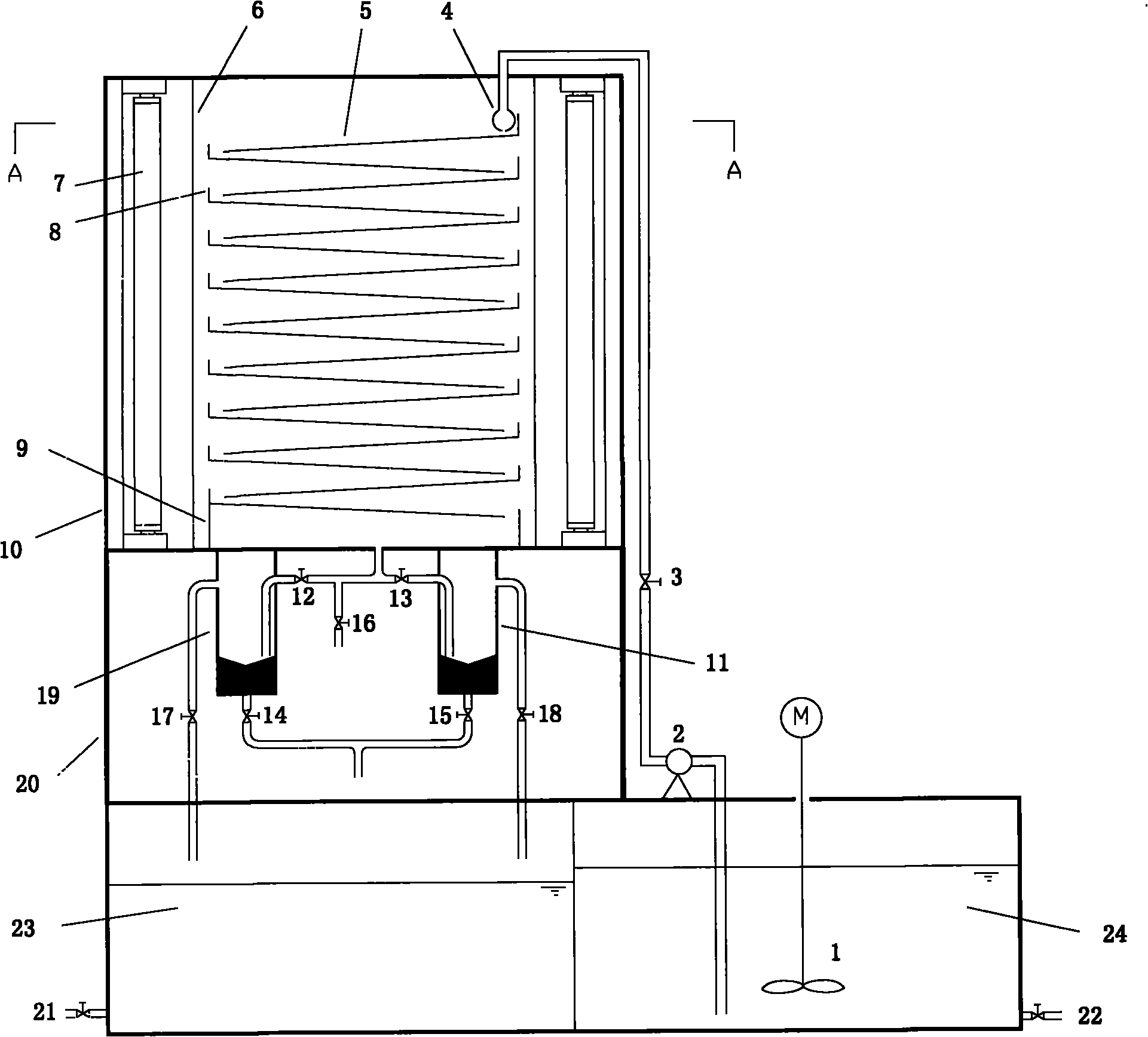

[0022] figure 1 The meanings of the labels in are: 1- agitator; 2- water supply pump; 3- flow regulating valve; 4- water distributor; 5- inclined plate; Water receiving tank; 10-shell; 11-No. 2 separator; 12-No. 1 separator water inlet valve; 13-No. 2 separator water inlet valve; 14-No. 1 separator emptying valve; 15-No. 2 separator Empty valve; 16-sampling valve; 17-1 separator overflow valve; 18-2 separator overflow valve; 19-1 separator; 20-support column; 21-clean water tank drain valve; 22- Sewage tank drain valve; 23-clean water tank; 24-sewage tank.

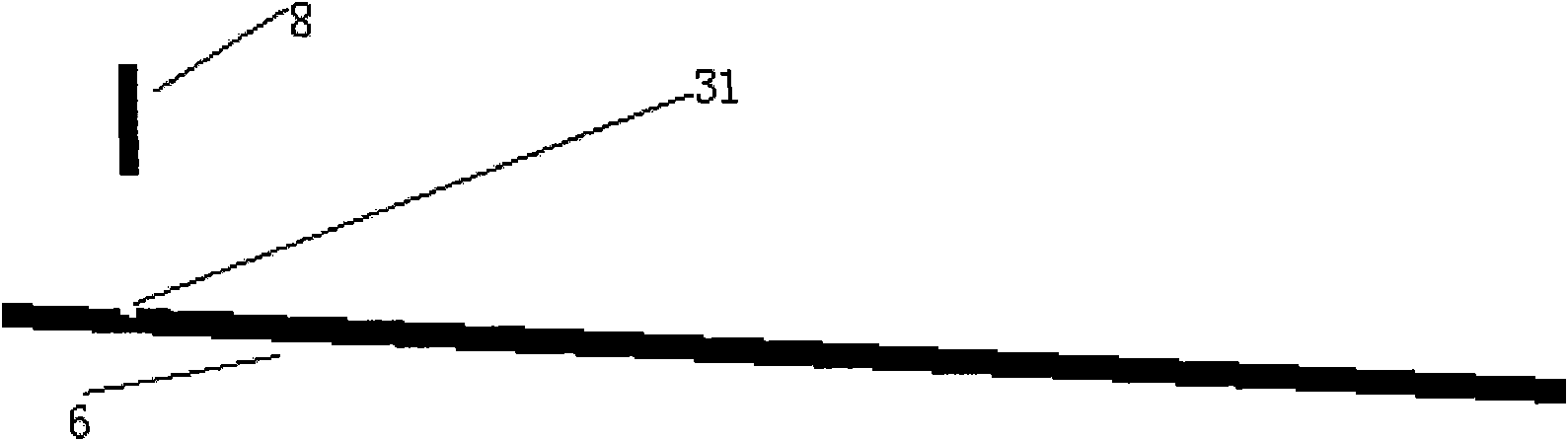

[0023] figure 2 The meanings of each label in are: 5-slope; 8-baffle; 31-groove.

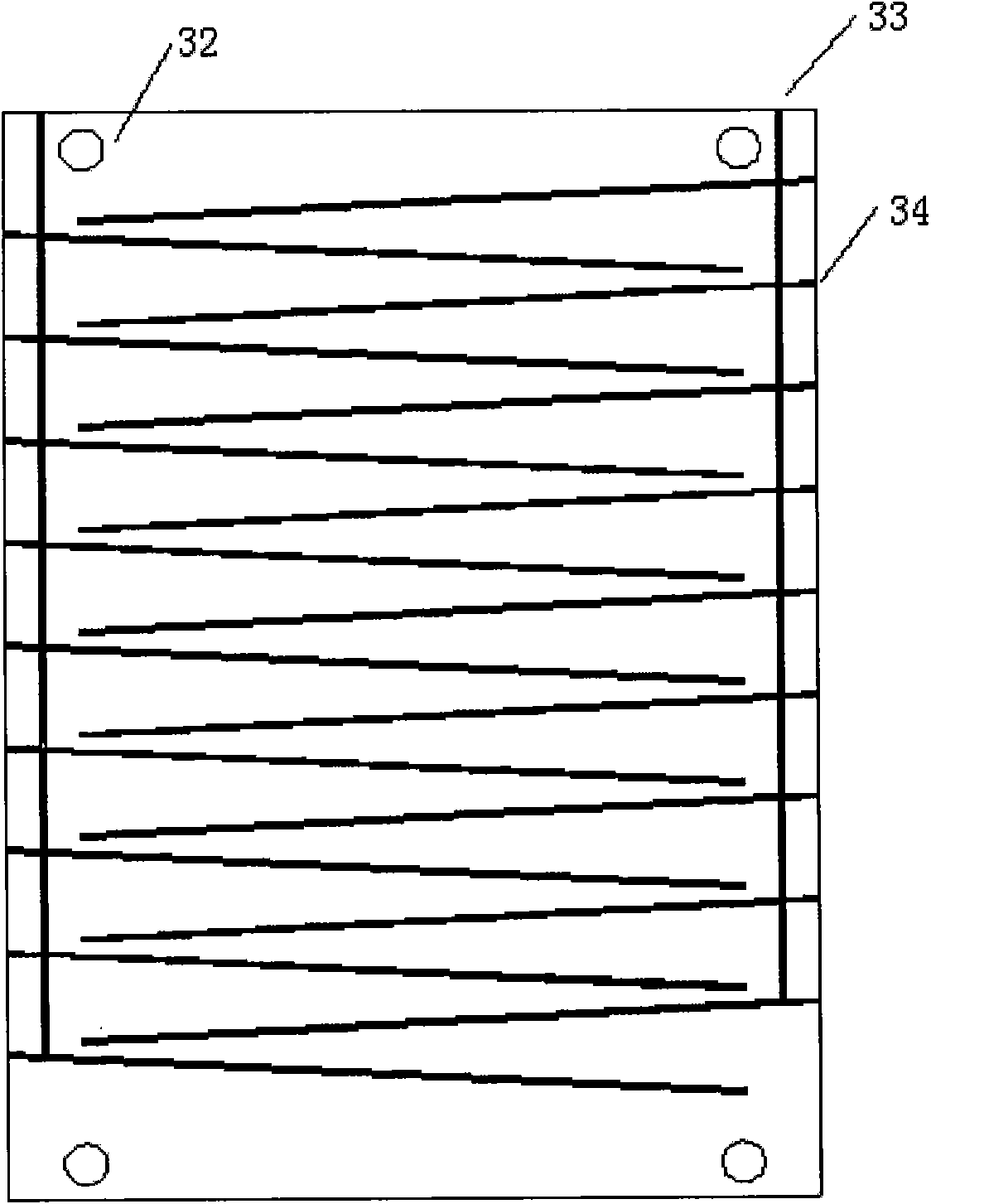

[0024] image 3 The meanings of each label in : 32-bolt hole; 33-longitudinal groove; 34-oblique groove.

[0025] Figure 4 The meanings of the labels in are: 7-light source; 6-partition; 8-baffle; 4-water distributor; 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com