Method for recycling blast furnace gas

A blast furnace gas separation and recovery technology, applied in the field of blast furnace gas recovery and utilization, can solve the problems of low added value of blast furnace gas, poor utilization effect, inability to fully utilize the advantages of blast furnace gas composition and chemical properties, etc., and achieve high energy utilization rate , the effect of good use effect and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

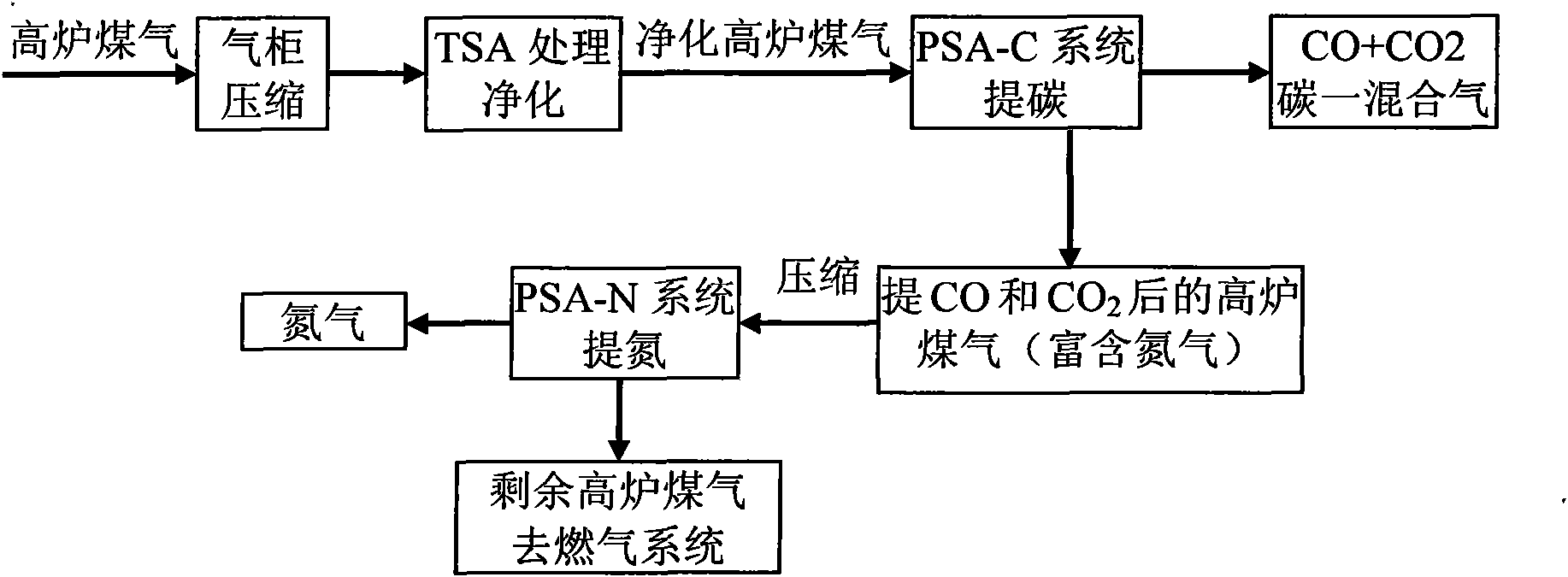

[0011] Embodiment 1: The method for recycling blast furnace gas in this embodiment is realized through the following steps: 1. Pass the blast furnace gas into the gas holder, then compress the blast furnace gas in the gas holder to a pressure of 0.01-0.1 MPa, and then Pass the blast furnace gas into the temperature swing adsorption system (TSA) for processing, control the inlet temperature of the temperature swing adsorption to be 300-400°C, and the outlet temperature to be 170-200°C to obtain purified blast furnace gas; 2. Add the purified blast furnace gas obtained in step 1 to After the pressure reaches 0.2-5MPa, it is sent to the pressure swing adsorption carbon extraction system (PSA-C) to adsorb and purify the carbon-mixture gas. Under the condition of gauge pressure of -0.1MPa~0.15MPa, desorb for 1min~10min to obtain CO and CO with a volume purity of more than 95%. 2 3. Pressurize the remaining blast furnace gas discharged from the gas outlet of the pressure swing adsor...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, the blast furnace gas in the gas tank is compressed to a pressure of 0.03-0.08 MPa. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, the blast furnace gas in the gas holder is compressed to a pressure of 0.06 MPa. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com